Working of Aspirating Smoke Detection

Introduction

Aspirating smoke detection ensures reliable fire detection in demanding application areas, where very early fire detection is required and business continuity is paramount. Aspirating smoke detectors continually draw samples of air from the areas requiring protection and evaluate these samples for the presence of smoke.

The basic ASD system has three main components :

• The network of sampling pipes, which collects the air through sampling holes and transports it from the protected space to the detector, where the presence of smoke particles is tested.

• An aspiration smoke detector consisting of:

– A detection chamber with a high sensitivity sensor to detect smoke particles suspended in the air

– A vacuum cleaner or fan to extract air from the protected area to the detection chamber

– An optional filter to remove all large particles that can damage the sensor inside the detection chamber

• The exhaust pipe to expel the sampled air from the detector.

Sampling Pipe Network

The sampling pipe network is connected to a port on the top or bottom of the detector. It’s typically constructed of plastic, but can be made of copper, brass, or another non-ferrous metal. Individual manufacturers have specific requirements for sampling pipe. The type of pipe is determined by the specific application and specified in the design software.

There are several methods of installing a sampling pipe network:

• Single pipe configuration, with one (1) pipe connected to the detector and extending through the entire covered space. Selecting this configuration may result in longer pipe runs and delay sampled air collection at the detector.

• Multiple pipe configuration , composed of multiple or branched pipes.

The sampling tube can be installed horizontally at roof level, in racks or vertically for warehouse and atrium applications . For hidden locations, the sampling pipe can be hidden in an empty space with smaller capillary tubes to sample the space .

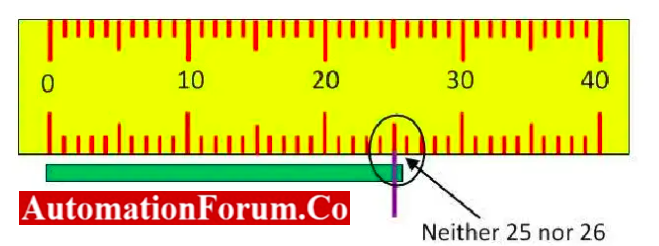

The pipe network contains sampling holes that allow air to enter the pipe. The sampling hole spacing is determined by the type of detection system being installed, which depends to a large extent on the type of application (for example, warehouse, data center, historic buildings). The individual sampling holes are sized according to the design software, which considers the fluid dynamics of the ASD systems and the type of design criteria of the detection system.

All ASD systems contain similar equipment, but the detector technology type varies. Currently, there are several

Types of detection technologies:

• Laser-Based Systems (Filtered) – This method utilizes a laser as the light source within the detection chamber. First, the air passes through a filter system to remove all large particles. The filtered air sample then passes in front of the laser, and the light scatter caused by the smoke particulates is measured by a photo collector. The detector’s sophisticated electronics determine the quantity of smoke particles within the chamber.

• Laser-Based Systems (Non-Filtered) – This method, commonly referred to as “Particle Counting,” also utilizes a laser as a light source in the detection chamber. However, in this configuration, the air is sent directly to the sensing chamber instead of passing through a filter. As the air passes in front of the laser, a photo collector counts the number of particles within the specified micron size to determine if sufficient smoke particulates are present. The laser technology’s sophisticated electronics differentiate between suspended dust particles and smoke particles

within the sample.

• Cloud Chamber – This method is the oldest and original aspirating technology. The sensing element is a sealed chamber containing extremely dense water vapor. When a charged smoke particle interacts with the dense water vapor, the particle is ionized. The resulting ions act as condensation nuclei around which a mist will form (because the original water vapor is extremely dense and on the verge of condensation). This process amplifies the size of the particulate from something that was below the wavelength of light (invisible) to a size far above the wavelength

of light (visible). The particulate will then be sufficiently sized and the photo cell inside the chamber will detect the mist/smoke particulates.

• Dual Source Sensor – This method utilizes a blue LED to detect extremely low concentrations of smoke and an infrared laser to identify nuisances like dust that can cause false alarms. Advanced algorithms interpret signals from both sources to determine if the sample is smoke or dust suspended in the air. Detected particulate levels could be as low as 0.00046% per foot (0.0015% per meter) obscuration.

Also read