Level Measurement

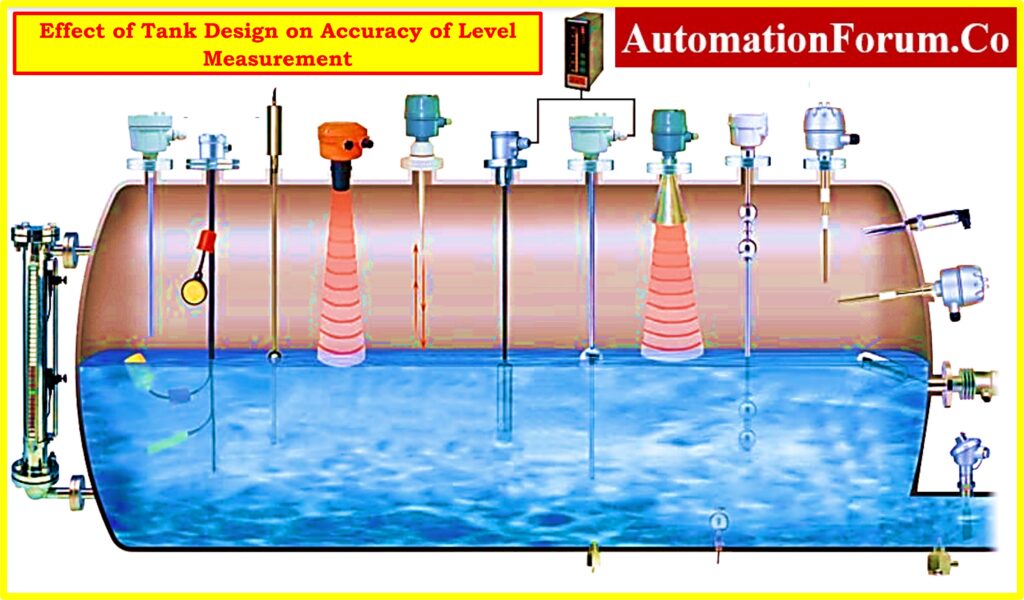

Effect of Tank Design on Accuracy of Level Measurement

Table of Contents

- Tank Shape and Geometry

- Tank Size and Height

- Construction Material

- Tank Wall Thickness

- Effects of Sloshing and Waves

- Pressure and temperature

- Properties of Liquids

- Fumes and Vapors

- Calibration and Sensor Positioning

- Agitators and Baffles

- Maintenance and Human Error

- Environmental Aspects

- Technology for Level Measurement

- Control System Integration

- Concerns Regarding Safety

In many industrial applications and processes, including as manufacturing, chemical processing, oil and gas, water treatment, and others, level measuring is a crucial component. In order to monitor processes, manage inventories, and ensure secure and effective operations, level readings must be accurate.

The tank’s design has a big impact on the accuracy and reliability of level measurements. Let’s examine each of the key elements in greater detail:

Tank Shape and Geometry

- Tanks come in different shapes and geometries, such as cylindrical, spherical, rectangular, or irregular.

- Cylindrical tanks are commonly used due to their simple design, providing consistent and predictable level measurements.

- Irregular shapes or complex geometries may introduce measurement errors due to uneven distribution of contents, leading to variations in measurements.

Tank Size and Height

- The size and height of the tank can affect the accuracy of level measurement.

- Due to the relative greater influence of sensor tolerances, readings of smaller tanks may have higher percentage errors.

- Taller tanks can introduce hydrostatic pressure variations, impacting measurement accuracy and requiring compensation for pressure effects.

Construction Material

- The tank’s material can affect the accuracy of level measuring.

- Non-metallic or non-conductive materials, for example, can have an impact on the performance of level measurement technologies such as capacitance or conductive sensors.

- Due to electromagnetic phenomenon, metal tanks may cause signal interference for several non-contact level measuring devices.

Tank Wall Thickness

- The thickness of the tank walls can impact level measurement accuracy.

- Thick walls can reduce signal penetration for certain technologies, leading to less precise measurements.

- For ultrasonic or radar-based measurements, thick walls may also introduce reflections and echoes that affect the accuracy of readings.

Effects of Sloshing and Waves

- The presence of sloshing and waves in the tank can result in measurement errors.

- These effects can be most noticeable in tanks containing free surface liquids, such as gasoline tanks on moving vehicles or ships.

- In such instances, specific strategies or technologies may be necessary to adjust for sloshing effects.

Pressure and temperature

- To achieve accurate level measurements, tank design should take temperature and pressure variations into account.

- Temperature changes might cause the liquid to expand or contract, affecting the observed level.

- Thermal influences might cause the tank to expand or contract. This can have a big influence on level-based measurements instead of volume measurements since an extended tank might have more fuel in it at a certain midpoint than it would have at the same midpoint without expansion.

- High-pressure conditions can have an impact on the performance of some measurement devices, requiring pressure corrections.

Properties of Liquids

- The physical qualities of the liquid being measured can have an impact on the accuracy of the level measurement.

- Certain level measurement devices may be hampered by liquids with high viscosity or low dielectric constants.

- Proper measuring equipment selection can account for these qualities and provide reliable measurements.

- The expansion of the shell caused on by the substance contained

Fumes and Vapors

- Tanks containing volatile liquids can emit vapors and fumes that can interfere with certain level measurement systems, such as ultrasonic or optical sensors.

- To ensure measurement accuracy, proper ventilation or the use of vapor-resistant sensors may be required.

Calibration and Sensor Positioning

- Accurate level measurements require proper calibration and sensor positioning.

- Calibration ensures that the readings correlate to the liquid’s real level.

- To avoid incorrect readings, sensor placement should take into account the tank’s internal features as well as potential obstacles.

Agitators and Baffles

- Tanks containing baffles and agitators might have an impact on level measuring accuracy.

- Wave reflections caused by baffles can result in misleading level measurements during measuring.

- Agitators can cause disturbances on the liquid surface, altering its stability and introducing measuring inaccuracies.

Maintenance and Human Error

- Human error during tank installation or maintenance can result in inaccurate level measurement.

- To maintain sustained accuracy, regular maintenance and calibration checks are required.

- Human errors can be reduced by properly training workers involved in tank operations and level measurement.

Environmental Aspects

- External environmental conditions can have an impact on the accuracy of level measurement.

- Sensor performance can be impacted by vibrations, electromagnetic interference, and temperature variations.

- Sensor shielding or isolation may be required in settings with severe electromagnetic interference.

Technology for Level Measurement

- The level measurement system selected should be compatible with the tank design and intended application.

- Ultrasonic, radar, capacitance, and hydrostatic technologies all have variable degrees of the suitability for various tank designs.

- Each approach has advantages and disadvantages, and the best option is determined by criteria such as tank size, contents, and environmental conditions.

Control System Integration

- The accuracy of level measurement should be in line with the overall control system requirements.

- Disagreements in level readings may result in inefficiencies in process control or inventory management.

- Monitoring and communication between level sensors and control systems in real time can help to optimize operations.

Concerns Regarding Safety

- To avoid spilling or overfilling, tank design should prioritize safety, which can affect level measuring accuracy.

- Even in critical circumstances, proper safety procedures can assure reliable and precise measurements.

- In the event of incorrect level readings, safety shut-off mechanisms can prevent catastrophic events.