- What is a Pneumatic Valve ?

- Key Components of the Pneumatic Valves

- What is the Function of Pneumatic Valve ?

- What is Pneumatics ?

- How does a Pneumatic Controlvalve Work ?

- What are the Types of Pneumatic Valve

- What are the Major Components in a Pneumatic Valves ?

- What are the Types of Pneumatic Actuator ?

- Applications of Pneumatic Actuators

- What is the Purpose of the Actuator ?

- Types of Actuation in Pneumatic Actuators

- Applications of Pneumatic Valves

- How is a solenoid valve is different from a pneumatic valve ?

- What is a 3-way pneumatic valve ?

- What is an electro-pneumatic valve ?

What is a Pneumatic Valve ?

A pneumatic valve is a mechanical device used to control the flow of compressed air within a pneumatic system. These valves are crucial for regulating air pressure, directing airflow, and controlling the speed and movement of pneumatic actuators, such as cylinders and grippers.

Key Components of the Pneumatic Valves

- Air Supply: The source of compressed air, usually generated by a compressor and stored in an air receiver tank.

- Air Pipes or Hoses: These transport compressed air from the supply to various parts of the system.

- Actuators: Devices that convert the energy from compressed air into mechanical motion. Common types include pneumatic cylinders and grippers.

- Controls: These include various manual or automated devices for operating the pneumatic system.

- Valves: These control the direction, pressure, and flow rate of the compressed air.

What is the Function of Pneumatic Valve ?

A pneumatic valve is also known as directional control valves, the major function of a pneumatic valve is to switch airflow. These valves are capable to maintain the pressure. The range of pneumatic valves is vast and there are many categories of pneumatic valves. Pneumatic valves are categorized according to their style, type, design principle, type of operation, function, size, and application. The pneumatic valve can do the simplest function of switching a single flow path on and off, to the exacting proportional control of pressure and flow. The valves which are used in pneumatics mostly have control function, this can be described as the operation of the valve in any process or the controlling of a quantity. A control function requires control energy, we could know the control energy by the mode of actuation it can be manual, mechanical, hydraulic, or pneumatic.

What is Pneumatics ?

Pneumatics can be described as the use of pressurized air to some mechanical motion. Pneumatics are also used in control valves, pneumatics has many applications in different industries. It also has other applications such as dentistry, construction, and mining. The fuel for pneumatic power is air.

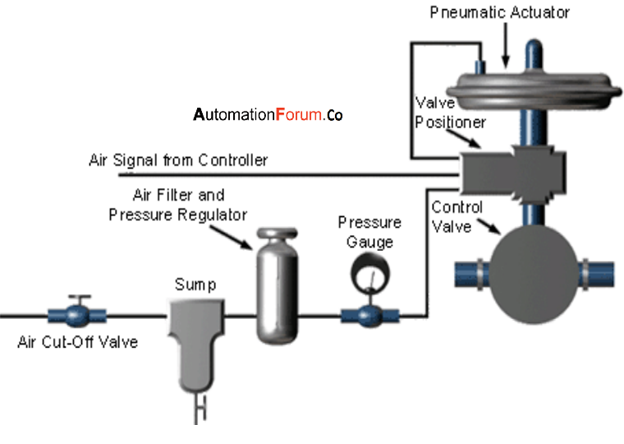

How does a Pneumatic Controlvalve Work ?

Pneumatic control valves can decrease pressure in a controlled manner with the help of actuators and positioners with a controller to pilot them. Controllers are able to sense the pressure fluctuations and they can regulate the air supply signal to the pneumatic positioner. A pneumatic positioner would supply air to the diaphragm opening a valve. Springs are utilized as an opposing force causing the valves to close upon loss of or a reduction of air pressure applied on the diaphragm. Pneumatic control valves are widely used in many industries.

What are the Types of Pneumatic Valve

Pneumatic valves are categorized by function into: directional control valves (control flow direction), non-return valves (prevent reverse flow), flow control valves (regulate flow rate), and pressure control valves (maintain system pressure).

Directional control valves

The important function of a directional control valve is to control the direction of flow in the pneumatic circuit. These valves can regulate the airflow and they are also capable to do the airflow starting and stopping. Directional control valves are able to control the way the air passes.

Direct airflow to different parts of the system, commonly using a sliding spool mechanism. Examples include:

- 2/2-way valves: Control the flow of air in two positions – open or closed.

- 3/2-way valves: Direct air to one of two outputs, allowing for switching between two circuits.

- 4/2-way and 5/2-way valves: Used in more complex systems to control multiple actuators.

Non-return valve

These valves are also used to control the flow of air and they allow the airflow only in one direction in the other direction the airflow will be blocked at all the time. These valves are designed in a way that check is additionally loaded by the downstream air pressure, and it would support the non-return action. There are certain non-return valves those can do pneumatic controls they are check valve, shuttle valve, quick exhaust valve, and two pressure valve.

Flow control valves

This valve is capable to regulate the flow of air and the control action is limited to the airflow passing through the valve, when it is open, maintaining a set volume per unit of time.

Manage the rate of airflow to control the speed of actuators. Examples include:

- Throttle valves: Restrict airflow to control actuator speed.

- Needle valves: Allow precise adjustment of flow rate.

Pressure control valve

In pneumatically operated control valves pressure control can be done, these types of control valves can control the air pressure in the valve. So basically these valves can control the airflow pressure in valves. Pressure control valves are classified into three types they are pressure limiting valve, pressure sequence valve, and pressure reducing valve.

Regulate the pressure of the compressed air in the system to ensure it stays within safe and functional limits. Examples include:

- Pressure relief valves: Release excess pressure to prevent system damage.

- Pressure regulators: Maintain a constant output pressure regardless of input pressure variations.

What are the Major Components in a Pneumatic Valves ?

In a pneumatic valve, the valves control the switching and routing of air. The valves have to control the flow of compressed air and they need to control the flow of exhaust to the atmosphere. In a pneumatic switching circuit two types of valves are used they are 2/3 valve and 2/5 valves. The air cylinder comes in a variety of sizes and shapes. The major function of a cylinder is to convert the energy in the compressed air into straight motion.

What are the Types of Pneumatic Actuator ?

Pneumatic actuators convert compressed air energy into mechanical motion. Here are the main types:

Rotary Actuators:

These actuators produce rotational motion. They are used in applications requiring rotation, such as turning a valve or rotating a component. Common types include rack and pinion actuators and vane actuators.

Pneumatic Cylinders:

Also known as air cylinders, these actuators provide linear motion. They are widely used for pushing, pulling, lifting, or lowering loads. Types include single-acting cylinders (air pressure moves the piston in one direction, with a spring returning it) and double-acting cylinders (air pressure moves the piston in both directions).

Grippers:

These actuators are designed to grasp or hold objects. They are used in automated systems to pick and place items. Grippers can be parallel (jaws move in parallel) or angular (jaws move in an arc).

Rodless Actuators:

These provide linear motion without the use of a piston rod. Instead, the load is carried by a carriage that moves along the actuator body. They are used in applications where space constraints make traditional cylinders impractical.

Vacuum Generators:

These create a vacuum to hold or manipulate objects. They are often used in packaging, pick-and-place, and material handling applications.

Click here for Basic Types of Control Valve Actuators

Applications of Pneumatic Actuators

where are pneumatic actuators used?

Pneumatic actuators are used in various industries for their reliability, simplicity, and cost-effectiveness. Some common applications include:

- Automatic Valve Operation: Pneumatic actuators are widely used to control the opening and closing of valves in industrial processes.

- Manufacturing: For tasks such as assembly, packaging, and material handling.

- Automotive: In braking systems, suspension systems, and other vehicle controls.

- Food and Beverage: For packaging, bottling, and processing.

- Healthcare: In medical devices and laboratory automation.

- Robotics: To provide movement and control in robotic arms and other automated systems.

What is the Purpose of the Actuator ?

The primary purpose of a pneumatic actuator is to convert the energy from compressed air into mechanical motion, which can be either linear or rotary. This motion is used to:

- Control Valves: Actuators are integral to the operation of control valves, where they convert air signals into valve stem motion. They can throttle valves for precise flow control or provide quick opening and closing for on/off control.

- Perform Mechanical Work: Actuators enable various mechanical operations such as pushing, pulling, lifting, rotating, and gripping.

- Automate Processes: By integrating actuators into automated systems, processes can be made more efficient, reliable, and faster.

Types of Actuation in Pneumatic Actuators

- Reverse Acting: In this configuration, the actuator opens the valve when air pressure is applied and closes it when the air pressure is released, with the help of a spring.

- Direct Acting: In this type the actuator closes the valve when air pressure is applied and opens it when the air pressure is released, with spring action.

Applications of Pneumatic Valves

Pneumatic valves are used in various applications, including:

- Industrial Automation: Controlling machinery and robotic arms.

- Manufacturing: Operating presses, lifts, and conveyer belts.

- Automotive: Managing braking systems and other vehicle controls.

- Healthcare: Powering pneumatic tools and devices.

How is a solenoid valve is different from a pneumatic valve ?

The operation of the solenoid valve is entirely dependent upon electricity but the pneumatic valve operates with the help of electromagnetic force. Compressed air is also used for the movement of the parts.

What is a 3-way pneumatic valve ?

Mostly three-way valves are similar to two-way valves and the difference is that an extra port is used to for exhausting downstream air. These valves are able to control single acting or spring return cylinders and any load that must be pressurized and alternately exhausted

What is an electro-pneumatic valve ?

Electro-pneumatic valves are used for simple on-off function, in this valve we can control the pressure by manually opening a valve, automatically by detecting its pressure or by sending an electrical signal.

Click here for more about Control Valves

Click here for more about Valves

To get more info about the control valve check the following link