What are the parts of control valves and what are the accessories used in control valves

Why do we need control valves

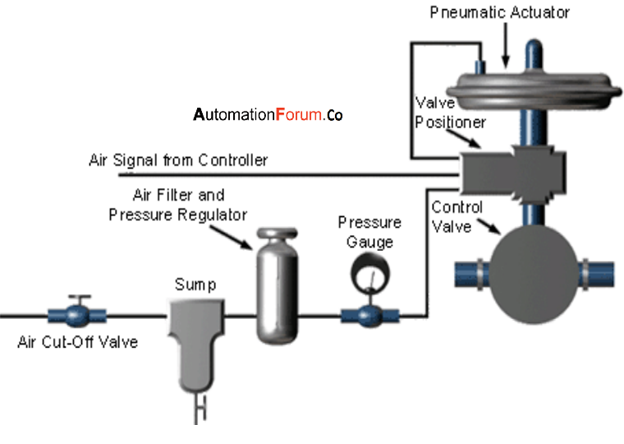

Control valves are used to control the flow of the liquid, it can regulate the fluid flow when the position of valve plug or disk is changed from the force from actuator to do this the valve must not have fluid with external leakage and it also requires a proper capacity for this service. The valves must be capable to withstand the corrosive and temperature influence of the process. The valve must have proper end connections to combine with the pipeline and actuator attachments control valves are divided into linear and rotary motion valves. Control valves are widely used in process plants and it will help to reduce the load disturbances.

- Valve body – it is the pressure carrying part and it is able to handle the pressure and temperature. The piping connection ends are given by this it also supports the seating surface and provides the fluid flow passageway.

- Bonnet assembly – it is the portion of the valve which has the packing box and stem seal, it could guide the stem and it may provide attachment of the actuator to the valve body. Usually, bonnets are welded threaded, welded or pressure sealed with the body.

- Trim – trim can be considered as the heart of the valve, with a primary function to proportion the valve orifice in a way that the prescribed relationship exists between flow capacity and valve plug lift. This is the valve’s internal component and can modulate the flow of controlled fluid.

- Valve plug – this is the movable part of the valve which is placed in the flow path to modulate the rate of flow through the valve

- Guide bushing – The bushing is fitted to the body, bonnet, bottom flange to guide the plug’s post.

- Cage – This is a part of the valve trim, in a globe or angle body, that surrounds the closure member and its flow passages could provide flow characterization or a seating surface, it could also provide stability, guiding, balance, and alignment.

- Seat ring -It is a part of the valve body assembly which would provide a seating surface for the closure member and may provide part of the flow control orifice.

- Seat – This is the contact between the closure member and its mating surface which establishes wall shutoff.

- Stem connector – It is the device which connects the actuator stem to the valve stem

- Yoke – it is the structure which connects the actuator power unit to the valve

- Actuator – the function of an actuator is to provide the motive force to operate a valve mechanism

- Positioner – A positioner is a device that is attached to the actuator, the controller will give an electronic or pneumatic signal to the positioner and the signal is compared to the actuator position. If the actuator position is different from the signal then the positioner, then the positioner sends the required power mostly through compressed air to change the actuator position.

What is valve sizing and how to do effective valve sizing

Valve sizing is the procedure of matching the dynamics of a process system to the performance characteristics of the valve. Valve sizing is important and this will provide the ability to manage the flow in the power system. I order to do the valve sizing properly certain details are needed for the system such as pressure before and after the control valve, flow rate quantity and units, process temperature with units and properties of the media and the details which are required for the control valve is flow capacity, inherent throttling curve, cavitation index, and critical flow factor.

What are the control valve accessories

Air pressure regulator

This is the most required accessory for the control valve it could be an air filter cum pressure regulator. This device is designed to furnish the reduced air supply pressure to the valve positioner. The filter portion in this device will remove the particulate matter which is large enough to clog the instrument nozzle.

Valve positioner

This can be considered as a relay that is capable to detect the instrument signal and valve position. This device is used to split the range values to reverse the signal to a valve. So that the friction in the valve can be removed.

I/P converter

This is an electro-pneumatic signal converter which is used as a linkage component between electric, electronic or pneumatic systems

Reversing relay

This device is used when the action from the controller is needed to be reversed

Hand-wheel

This device is used for the manual operation of the control valves, in case of emergencies like during the start-up or in case of air failure.

Limit switch

This is the switch that activates when the position of the device crosses a given physical limit.

Solenoid valve

It’s an electromagnetic device and its purpose is to move the plunger up or down if the current is passed through a coil that surrounds the plunger

To know more about control valves check the following links