A cartridge valve is a directional control valve, it is a two-position valve and because of this four such valves are needed to do the direction control. The cartridge valves are considered as pressure, directional, and flow control valves and this valve will be screwed to a threaded cavity. These valves are mostly used for low flows. The cartridge valves are small in size and it has fast switching speeds. These valves are of low cost and because of this, the cartridge valves are used in motion control and fluid power system. The cartridge valves are available in many configurations like on/off, proportional, pressure relief, etc. A cartridge valve will be screwed into the valve block and it would be able to do the logical and automated functions.

- What is an anti-surge valve and what are their functions?

- What are the problems in a control valve and how to do the troubleshooting and maintenance of a control valve?

- What is a single-seated and double-seated valve and how are they different from each other?

- What is a pilot valve and how does pilot valve work

- What are the types of pressure control valves and how does it work

- What is a directional control valve and what are the types of DCV

What is the need and use of a cartridge valve?

The integrated hydraulic circuits are compact hydraulic systems and they are created by using many cartridge valves and other components into a single, machined, ported manifold block. A cartridge valve is designed to be assembled into a cavity of a ported manifold block, this could be done with other cartridge valves and hydraulic components. In order to function the valves intended function, the cartridge valve is assembled into the manifold block either by screw-threads or by a bolted cover. Cartridge valves are composed of a combination of inserts and various control covers to provide the valve functions in hydraulic circuits.

What are the features of a cartridge valve?

- Less leakage when compared to the spool-type valves

- Good response

- The cartridge valve system that has inserts and control covers incorporated in the manifold blocks reduces the control circuit piping and saves space.

- By using one cartridge we can do many control functions

How does a cartridge valve operates?

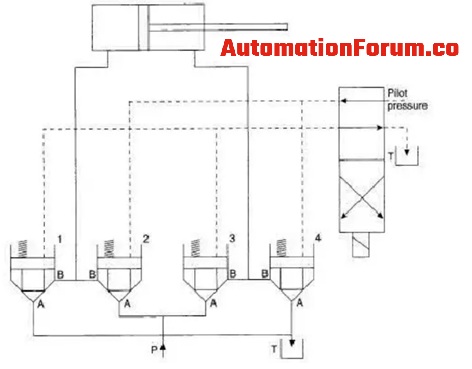

As we discussed above a cartridge valve is a two-position valve, so in order to do the direction control, four cartridge valves are used. These valves are operated in pairs by solenoid-operated two position valves, 2 and 4 would cause the cylinder to extend and 1 and 3 would cause the cylinder to retract. The cylinder would drive to a fully extended or fully retracted position. If the cylinder was required to hold an intermediate position the single two-position solenoid valve will be replaced by a three-position center blocked valve with one solenoid for extending and the other one for retracting.

These valves are a type of poppet valve and they are specially designed to fit in a block. Most of the valves can be designed as a cartridge in order to fit into a block, so in this way, a bank of valves can be built into one block. So this block could contain directional valves, relief valves, flow dividers one-way valves, etc.

How to install a cartridge valve?

The cartridge valve can be installed between the actuator and possible line breakage points. This type of valve can be installed into an actuator port, a housing-type cartridge valve can be installed close to the actuator or directly into the actuator.

What are the advantages of cartridge valves?

- Minimum leakage problem

- They are lightweight and small

- Less operation noise

- This valve can be used to stop and start the fluid flow and it can also be used to change the direction of the fluid flow

- System response can be improved

- Less energy consumption

- Good stability

- Good reliability

What are the applications of cartridge valve?

We can use cartridge valves according to the control input

- These valves can be used as directional control valves it can do the start, stop, and direction control process

- Pressure control valves

- Check valves

- Flow control valves