A flange is a device that can be used to connect two pipes mechanically, it can also do the connection of a pipe to a tee, valve, choke, or any other equipment to form a piping system. The flanges are elements of a pipeline that would allow the assembly of parts, it is an element that can be supplied as a separate part or as a part that is attached from the factory to an element such as a valve, pump, or another part. Basically, a flange is a kind of coupling that can join two lines together with the help of bolts and a gasket in between them. So the flange won’t individually make the joint. The flanged joints can be described as a combination of two flanges or it can be considered as bolting of two flanges and there would be a gasket in between these flanges.

- What is a subsurface safety valve?

- What is an emergency stop valve?

- What is a reversing valve?

- What is an anti-surge valve and what are their functions?

- What is a choke valve and what are the functions of the choke valve?

- What are the problems in a control valve and how to do the troubleshooting and maintenance of a control valve?

So the gasket between the flanges would give the seal, and the bolts provide forces which is required to seat the gasket and hold the joint together. The flanges provide the surface for the gasket to seal against and carry the applied forces around the gasket. The joint would allow easy disassembly and reassembly of piping or removal of components.

What are the characteristics of flanges?

- Holes are accurately drilled in the flange for the ease of the assembly

- The spot facing would ensure the seating of the fasteners true and square

- In order to obtain maximum strength, the grain flow is controlled

- Unrestricted flow is obtained by smooth and accurate bore

- Good welding is facilitated by machined bevel and land

- In order to ensure true alignments, all faces are machined within tolerances

What are the uses of flanges?

The need for flanges is increasing day by day, flanges are used for many industrial applications it is one of the best coupling methods to join two pipes. A flange would work properly if the components of the flange work properly. Flanged joints are mostly used for the ease of maintenance, flanges are used when the joints need dismantling. In certain pipelines maintenance is needed frequently so breakout flanges are used at definite intervals on pipelines.

What are the need for gaskets in a pipe line and in a valve?

A gasket is a malleable material that could be soft or hard and it is inserted between the flanges in order to prevent leakage. Pressure will be applied to the gasket by bolting or by using a clamp in order to compress the gasket firmly in a place. The gaskets are made of different types of material and it can be selected according to process characteristics like pressure and temperature. Gaskets are used in a valve to prevent the leakage in the closure mechanism and it also can prevent the leakage of fluid to the atmosphere. It is used in valves to allow the function of internal mechanisms that depends on separate fluid chambers like a pressure balance trim.

What are the types of flanges?

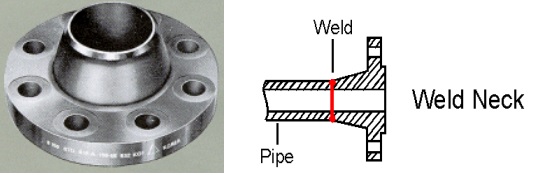

Weld neck flanges

This type of flanges is attached to the pipe by butt welding, mostly these flanges are used for critical services. So these flanges are suitable for handling extreme pressure and temperature and because of this feature, these flanges are mostly used for petrochemical and refinery plants. The bores of both the pipe and flange match and this would reduce the turbulence and erosion inside the pipeline. The weld neck flanges are bored to the ID of the pipe and it has a high neck into which the pipe is welded. This flange is considered the best welding flange due to its high, heavy neck.

Slip on flange

This flange is slipped over the pipe and after that, it will be fillet welded, there will be two fillet welds and these welds are at the inside and outside of the flange. This type of flange connection is very fragile when compared to the weld neck type. Mostly these flanges are selected because of their lower installation cost and also because they can handle slight misalignment. These flanges are not suitable for high temperature, high pressure, or high external loading situations.

Socket weld flange

This type of flanges are bored only on one side and these flanges are used for small bore lines only. These flanges are suitable for small-size high-pressure pipelines. The bore of the pipe and the bore are the same and thus it has good flow characteristics. This type of flange will be welded to the ID of the pipe and counterbored slightly larger than the OD of the pipe to allow the pipe to be inserted and welded in place.

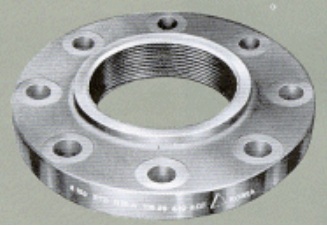

Threaded flanges

These flanges are made of steel and are used for special applications, the major advantage of this flange is that it can be connected to the piping without welding. In certain cases, a seal weld is also used in conjunction with the threaded connection. Screwed fittings are mostly used for smaller pipe sizes. These flanges are used to connect other threaded components at low pressure. The threaded flanges are mostly used for low pressure and low-temperature applications like water and air utility services. These flanges are inevitable in explosive areas because a welded connection in these areas would be dangerous. These flanges cannot be used with pipes that have thin walls due to the fact that thread cutting won’t be possible. Threaded flanges cannot be used for conditions involving temperature or bending stresses of any magnitude. Under cyclic conditions leakage through the threads could occur in few cycles.

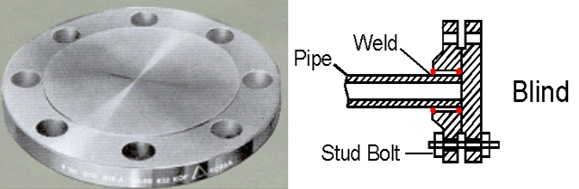

Blind flanges

These flanges are used to close the ends which need to be reopened later. These flanges are used to blank off the ends of the piping, valves, and pressure vessel openings. These flanges are constructed without a bore, from the standpoint of internal pressure and bolt loading, blind flanges which are in the larger size are the most highly stressed flange types. So basically a blind flange is a flat metal plate that is used to block flow in a piping system. By using this flange we can easily access the vessels or piping systems for inspection. We can use blind flanges for high temperature and pressure applications.

Lap joint flange

This type of flanges is used with stub ends when piping is of costly material. These flanges are cost-effective, in an expensive pipe such as stainless steel because of the fact that only the stub must match the pipe and the flange can be made of cheap carbon steel material. These flanges have less pressure holding capability, lap joint flanges can be used in services that require frequent dismantling for inspection and cleaning. In systems that would erode or corrode quickly, these flanges could be salvaged for reuse.

Long weld neck flanges

This type of flange is similar to the weld neck flange and the only difference is that their neck is extended and acts as a boring extension. This type of flanges is mostly used on vessels, columns, or barrels.

Orifice flanges

These flanges are used when an orifice plate or flow nozzle must be installed. Pairs of pressure tapings are machined into the orifice flange, thus making separate orifice carriers or tappings in the pipe wall. These flanges are used for instrumentation connections it is used in conjunction with a flow meter to indicate the flow.