- Thermocouple

- What are the different type of thermocouple?

- Thermocouple Types : Based on Base Metal

- Thermocouples Types: Based on Noble Metal

- Thermocouples Types: Based on refractory Metal

- Thermocouple output voltage response with low & high temperature.

- Summary of types of thermocouple

- Application of Thermocouple

- What is meant by element Chromel, Alumel & Constantan?

- How do we choose between different types of thermocouples?

- Why are Type K Thermocouples So Popular?

Thermocouple

A thermocouple is made up of two metal conductors of different metals that have been soldered together at the ends to form an electrical circuit. The Seebeck effect causes a voltage to be created when there is a temperature differential between the two joints, and when one of the two joints are opened, there is an electromotive force (emf).

The type of metals employed and the temperature that the joints are exposed to are the only factors that affect the polarization and strength of the electromotive force.

The joint between the thermocouple conductors and the measuring circuit is known as the cold junction or the reference junction, whereas the joint exposed to the temperature to be measured is known as the hot junction or the measuring junction.

In order for the emf generated to simply depend on the temperature of the measuring junction, the reference junction for a thermocouple must be at a specific temperature (often 0°). The materials that make up the conductors have an impact on the type of thermocouple.

What are the different type of thermocouple?

A thermocouple can be made from any sort of two dissimilar metals. The thermocouple is defined by the hot junction that forms between the two metal wires since different metals have different qualities. There are many different kinds of thermocouples, and each has special qualities in terms of temperature range, toughness, vibration resistance, chemical resistance, and applicability.

Thermocouple are broadly classified as Base metal, Noble metal & Refractory metal.Thermocouples come in eight basic varieties. The most popular thermocouple kinds are

- “Base Metal” Type J, K, T, and E thermocouples

- Noble metal “Type R, S, and B” thermocouples

- “Refractory metal” – Type W, W5and W3

Thermocouple Types : Based on Base Metal

Type K Thermocouple

- The most popular type of temperature sensor is the k-type, which has a positive (chromel) and a negative (alumel) component.

- This thermocouple is recommended for areas with corrosion or oxidation.

- Yet, according to the EMF effect from hysteresis, they do not perform properly at low temperatures.

- Otherwise, it is too accurate and trustworthy at high temperatures.

- It is inexpensive and accessible in a number of forms due to its popularity.

- Its operating temperature ranges from 95 to 1260°C.

- Its accuracy is typically +/- 2.2°C (or +/-.75%), their specific error tolerance is +/- 1.1°C (or +/- 0.4%), and their sensitivity ranges from 28 to 42 V/°C.

- Unless there is a strong reason K thermocouple is used rarely

Application of Type K thermocouple

- Utilized in dry areas, moderate chemical solutions, water, and mild chemical conditions.

- Found in vehicles, hospitals, oil heaters and boilers, and the food sector.

Type J Thermocouple

- Thermocouple with a copper-nickel alloy constantan (negative pole) and an iron positive pole is called J type thermocouple.

- This thermocouple has a temperature range of -210 to +1200 °C, although it has a shorter life cycle than K-type at high temperatures.

- With regard to price and dependability, it is comparable to the K-Type.

- They typically have an accuracy of +/- 2.2°C (or +/-.75%), a specific inaccuracy of +/- 1.1°C (or +/- 0.4%), and a sensitivity of 50–60 V/°C.

- Type J is less common than type K because of its narrow temperature range (-40 to +750 °C).

- Because an abrupt magnetic transformation will result in permanent de-calibration, J types should not be utilised over 760 °C.

- It is suited for detecting middle temperatures in decreasing environments and when carbon and hydrogen are present.

- Its ability to function correctly in oxidising environments is compromised by the presence of iron.

Application of a type J thermocouple.

- It is used in hot operations, such as the manufacturing of polymers and resin, as well as in vacuum, inert, and reducing environments.

- This thermocouple is mostly used in vacuum, reducing, and oxidising conditions.

Type E Thermocouple

- The E-type has a positive (Chromel) and a negative (Constantan) component and is not employed for oxidation in certain applications.

- While it should be avoided in sulphurous atmospheres, this type has a maximum EMF per degree.

- Type E is particularly suited for low temperature (cryogenic) application because to its high output (68 V/°C).

- Its lack of magnetic properties is another quality.

- The positive pole of the “K” type thermocouple and the “J” type thermocouple are combined to create a thermocouple with high thermos-electrical power.

- It is specifically suggested in oxidising environments.

- Between -95 and 900°C is the range of their temperatures. Its sensitivity ranges from 40 to 80 V/°C, and their precision is typically +/- 1.7°C (or +/- 0.5%), with an error limit of +/- 1.1°C (or +/- 0.4%).

Application of Type E thermocouple.

- Used below zero, in oxidising, or inert applications; cryogenic temperatures do not cause corrosion.

- Excellent for cryogenic chemical and pharmaceutical applications

Type T Thermocouple

- The T-type consists of a positive (Copper) and a negative (Constantan) part.

- In vacuum environments, they are frequently used for reducing and oxidising.

- It exhibits dependable resistance to disintegration in the majority of atmospheres and great stability at subzero temperatures.

- Their temperature ranges from -200 to 350 °C.

- The specific error restriction is +/- 1.1C (or) 0.4%, the precision is roughly +/- 2.2C (or) +/-.75%, and the sensitivity ranges from 17 to 58 V/°C.

Application of Type T Thermocouple

- Cryogenics and other applications involving extremely low temperatures typically make use of the Type T thermocouple because of its high level of stability.

- It is also present in many kinds of laboratories.

Type N Thermocouple

- Both a positive (Nicrosil) and a negative (Nisil) component make up the N-Type.

- According to temperature and hysteresis variations, it is quite resistant to degrading.

- It usually costs more than other kinds of thermocouples.

- They can be found in the temperature range of -250 to +1300 °C.

- Their accuracy ranges from +/- 2.2°C (or +/-.75%) to +/- 1.1°C (or +/- 0.4%), and their sensitivity ranges from 24 to 38 V/°C.

- ‘The type N is appropriate for high temperature measurements without the expense of platinum (B,R,S) types due to its great stability and resistance to high temperature oxidation.

- It is gaining popularity because it was created to be a “improved” type K. Similar to a type “K” thermocouple for high temperatures, but with less hysteresis.

Application of Type N thermocouple

- Used in ovens, furnaces, and kilns with vacuum or regulated atmospheres.

- Moreover, the iron, aluminium, and smelting industries, as well as gas turbine and engine exhausts.

Thermocouples Types: Based on Noble Metal

- Thermocouple types B, R and S are all ‘noble’ metal thermocouples and exhibit similar characteristics.

- They are the most stable of all thermocouples, but due to their low sensitivity (approx 10 µV/°C) they are usually only used for high temperature measurement (>300 °C).

- Due to their high cost and poor sensitivity, Type B, R and S thermocouples are often only utilised for high-temperature readings.

- To reinforce the thermocouple and avoid failures from grain growth that can happen in high temperatures and severe environments, HTX platinum wire can be used in place of the pure platinum leg in type R and type S thermocouples.

Type S Thermocouple

- Platinum and rhodium thermocouples, two noble metals, enable the acquisition of very precise readings.

- S type is made up of Platinum -Rhodium 10% in positive and Platinum in negative

- Due to its excellent resistance to high temperatures, it is frequently used in oxidising environments.

- It is not really indicated in lowering atmospheres or those with metal gases.

- Ideal for high temperature measurements up to 1600 °C.

- Due to their high cost and low sensitivity (10 V/°C), they are not suitable for widespread use.

- Because of its outstanding stability, Type S is used as the calibration standard for gold’s melting point (1064.43°C).

Applications of Type S thermocouple

- Used in extremely high temperatures employ the Type S.

- It is frequently encountered in the pharmaceutical and biotechnology sectors.

Type R Thermocouple

- Similar to the “S” type thermocouple, but using various ratios of the two metals.

- R type is made up of Platinum -Rhodium 13% in positive and Platinum in negative

- Suitable for measurements of high temperatures up to 1600 °C.

- The specific error is +/- 0.6°C or 0.1%, the accuracy is +/- 1.5°C (or) +/-.25%, and the sensitivity ranges from 8 to 14 V/°C.

- They are not appropriate for broad use because to their low sensitivity (10 V/°C).

- It costs extra because it contains a lot more rhodium than the S-Type nearly 50% more.

- Compared to type S, type R has a slightly higher output and better stability.

- For applications involving high temperatures, there is the R-Type. In low-temperature systems, it is used because of its great precision and dependability.

Type B Thermocouple

- The B-Type thermocouples have the highest temperature limitation of all the thermocouple kinds listed above, and they are widely used in high-temperature sectors.

- At very high temperatures, they operate with a high degree of precision.

- For the positive leg, it has platinum mixed with 30% rhodium, while for the negative, it has platinum mixed with 6% rhodium.

- the range of temperatures is 1370 to 1800 °C

- The sensitivity is between 5 and 10 V/°C, and the accuracy is between +/- 0.5% and +/-.25%. The specific error limitation is within +/- 0.25%.

Application of Type B thermocouple

- used widely in the steel and iron industries to keep an eye on the chemistry and temperatures of the steel-making process.

Thermocouples Types: Based on refractory Metal

- Thermocouples that contain rhenium and tungsten, whose chemical symbol is W, are the only ones that are exempt from the arbitrary nomenclature.

- The amount of rhenium in the positive leg is indicated by the number that follows the W. Example In the case of Type W5, the positive leg is composed of 95% tungsten and 5% rhenium. There won’t be rhenium in the positive leg if there isn’t a number.

- Very high temperatures can be measured with these thermocouples.

- Vacuum furnaces, hydrogen atmospheres, and inert atmospheres are common applications.

- Because to embrittlement, they are not usable in oxidising conditions at high temperatures.

- An average temperature range is 0 to 2315 °C, although this can be increased to 2760 °C in an inert atmosphere and 3000 °C for quick observations.

Types of thermocouple

- W5 or Type C

- W3 type or Type D

- either Type WR, Type W, or Type G

W Type or Type G thermocouple

- The tungsten-rhenium thermocouple system’s first combination to be created was Type G.

- Yet, the pure tungsten positive leg’s brittle nature makes it suffer.

- This is the main reason why the positive leg is typically transported in its drawn-out state.

- The thermocouple is then subjected to high operating temperatures (often > 2000°F), which causes an emf shift.

- The greater Seebeck coefficient attained at temperatures above 900°F is the main benefit of the G combination.

- This benefit’s value is downplayed by modern instruments.

- Both hipping ovens and heat treat ovens frequently employ these thermocouples.

W3 Type (or) Type D thermocouple

- It has a tungsten positive pole that is 3% rhenium rich, and a tungsten negative pole that is 25% rhenium rich.

- 2,320°C is its highest temperature range.

- The W3 thermocouple is designed for use in environments with temperatures that are exceptionally high.

- Extremely resilient in environments where reducing agents are present, as well as those where hydrogen or other inert gases are present. Air and other oxidising atmospheres are not suitable for use with this product.

Applications of W3 (or) Type D thermocouple

- Semiconductors, solar energy, and aerospace frequently use these thermocouples.

W5 or Type C Thermocouple

- Type C Thermocouples are created for exceptionally high temperatures and constructed of tungsten rhodium alloys (2315 °C).

- To avoid failure from oxidation, the thermocouple materials must be used in hydrogen, inert, or vacuum environments.

- Maximum Temperature Range is affected by the diameter of the bare wire, the protective sheaths, and, to a lesser extent, the connectors or extension wire leads that are attached.

- The W5 Thermocouple is quite comparable to the W3 kind, but it has a higher proportion of rhenium, which boosts its resistance to mechanical stress.

Application of Type C thermocouple

- These thermocouples are widely utilised in a variety of applications, including producing high-temperature materials, aerospace, power production, military and defence testing, semiconductor processing and equipment, and research.

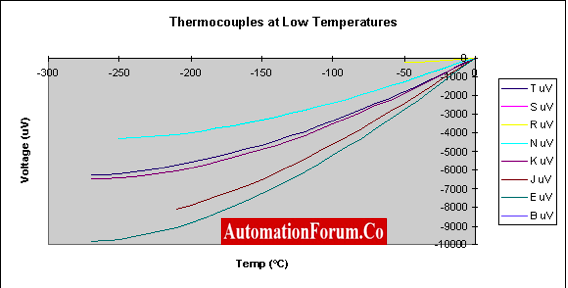

Thermocouple output voltage response with low & high temperature.

- The graphs that follow illustrate the voltage output of thermocouples at various temperatures.

- It is important to keep in mind that thermocouples based on platinum have a very low output, which is the reason why their employment is restricted to the monitoring of extremely high temperatures.

Summary of types of thermocouple

| Thermocouple Type | Materials used in positive leg | Materials used in negative leg | Maximum temperature | Application |

|---|---|---|---|---|

| K | Chromel | Alumel | 1260°C | Refineries |

| J | Iron | Constantan | 760 | Injection moulding |

| N | Nicrosil | Nisil | 1260°C | Refineries, Petrochemicals |

| E | Chromel | Constantan | 870°C | Power plants |

| T | Copper | Constantan | 370°C | Cryogenics, Freezers, Food production |

| R | Platinum-13% rhodium | Platinum | 1480°C | Sulfur recovery units |

| S | Platinum-10% rhodium | Platinum | 1480°C | Pharmaceutical, labs, Biotech, High Temperature Furnaces, |

| B | Platinum-30% rhodium | Platinum-6% rhodium | 1700°C | Glass production unit |

| W | Tungsten | Tungsten – 26% Rhenium | 2320°C | Semiconductors, Solar, Aerospace |

| W3 (or) D Type | Tungsten – 3% Rhenium | Tungsten – 25% Rhenium | ||

| W4 (or) C Type | Tungsten – 5% Rhenium | Tungsten – 26% Rhenium |

Application of Thermocouple

- Thermocouples are used for a variety of tasks, including monitoring the presence of a pilot light in gas-fed heating appliances like ovens and water heaters, as well as determining the temperature of the room itself.

- Thermocouples of the S, R, and K types find widespread application in the steel and iron industries, where they are used to monitor temperatures as well as chemistry throughout the steel-making process.

- The testing of prototype electrical and mechanical equipment can typically benefit from the utilization of thermocouples.

- Example: keeping an eye on the switchgears while the heat run test is being performed.

- The number of thermocouples that are used for logging and testing the various temperatures that are involved with a process is utilized in industries such as chemical production and petroleum refining.

What is meant by element Chromel, Alumel & Constantan?

- Chromel = Nickel-chromium

- Alumel = Nickel-aluminum

- Constantan = Copper-nickel

How do we choose between different types of thermocouples?

- Range of temperatures

- Several thermocouple types operate at varying temperatures.

- For instance, Type T’s copper component has a maximum temperature of close to 370°C.

Size of conductor

- When long cycle detection is used, the size and shape of the thermocouple wires must be taken into consideration.

- T-type thermocouples, for instance, are used up to 370°C if the primary system is made up of #14AWG wires (or 0.064″ Diameter).

- Nevertheless, the temperature range is only 150°C when the gadget uses 30AWG wires.

Accuracy

- The accuracy of T-type thermocouples is the highest among base metal thermocouple types.

- Following this are the types J, K, and N for ANSI/ASTM E230 standard restrictions of error, followed by E-Type.

- The sheath composition in probe devices, the insulating material in surface sensors, and sensor shape are some more crucial elements.

Why are Type K Thermocouples So Popular?

- Type K thermocouple can withstand a wide range of temperatures and are durable they are extremely popular.

- Comparing Type J (Iron) and Type T conductor metals to those used in them, they are more chemically static (copper).

- Although type K’s output signal is about lower than that of type T, type J, and type E, it is higher than type N, which is its main rival, and it has been employed more frequently than those other types.