Variable Area Flow Meter – Application – Working Principle – Advantages

Variable Area Flow Meters

Variable area flow meters are used to measure the volume flows of liquid and gases.

Application of Variable Area Flow Meter – Volume flow measurements of Liquids and Gases

Components – Vertical Conical Measuring Tube

Mobile Float

It consist of vertical conical measuring tube which widens upwards and a specially formed float which can move up and down freely in the measuring tube.

Working Principle –

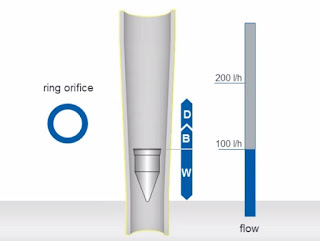

The reference of position of the float to the measuring tube creates a variable ring orifice.The higher the position of the float the larger the ring orifice and therefore the cross sectional area through which the medium come pass through the float.This is the origin of the English designation of the device.

When there is no flow, gravity keeps the float at the bottom end of the measuring tube.

As soon as the medium flows through the tube from bottom to top the float rises again until the acting forces are in balance.

Three main forces act on the movable float.

1. Graviatation force (W = Weight) – Operates downwards as a reset force.

2. Buoyancy force (B)

3. Flow force (D=Drag)

Weight = Drag + Bouyancy

W and B = Constant

The position of the float is a flow indicator.

The physical operating mode shows that the position of the float is a flow indicator.

With glass cones flow rate can be read on a scale on the measuring chip itself.

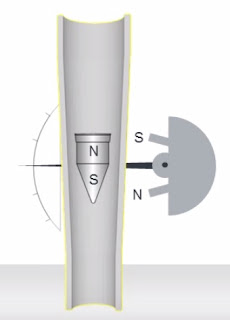

With the metal cones the float is not visible so they have a magnetic transfer onto the pointer.For this purpose a magnet is built into the float.Through a magnetic coupling installed on the point of axis the linear movement of the float float is converted into the rotary movement of the pointer which displays the flow on a scale.No auxiliary power supply is required.

Advantages of Variable area flow meter – Purely mechanical.No auxiliary power is requires.

Related posts –

Flow transmitter calibration

Type of Valves