Step by Step Procedure For Pressure Switch Calibration

How to do Pressure Switch Calibration [Step by Step Procedure]

Prerequisites

1.Safety First

-Please follow appropriate safety procedures as required by your company for the pressure range.

-Know the voltage to expect and confirm

-Isolate and Depressurize line

2.Understand the switch configuration

-Trip on decreasing or increasing

-NO or NC contact,Normal status

3. Orientation on test setup

-Keep same orientation when testing pressure.

4. Dont change input too fast.

5. Avoid leaking in test connection

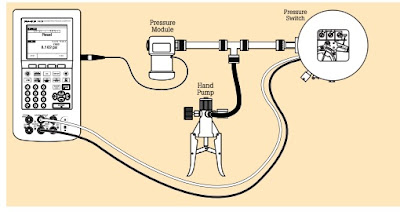

Equipment Required For Calibration

1.Pressure Source

2.Accurate Gauge

3.Micro switch contact monitoring device.

For high pressure application Hand pump is more suitable.

For low pressure shop air or simple regulated pressure can be used or electronic pressure source can be used.

Pressure should have an accuracy of 0.25 %.

Pressure Switch Calibration Procedure

1.First step of the calibration is to make sure the switch operating correctly. To test a switch give pressure from zero to full range of the switch.Then return back to zero.Repeat the step for 3 times.

2.To measure an increase in setpoint,start at 0 psi and increase the pressure to the setpoint ,the switch will actuate indicating the NO contact of the switch get closed.

3.To measure the deadband ,slowly decrease the pressure,the switch will actuate indicating switch NC contact is closed.Record the deadband.

4.To measure a decrease in setpoint,start at 0 psi and increase the pressure to full range.As the pressure increases the NO contact get closed. Then lower the pressure to reset point.Then NC contact becomes closed.

5.To measure the deadband slowly increase the pressure till the switch gets actuated .

Repeat the steps to verify repeatably.

You can do the adjustment in Pressure Switch as per manual.

Calibration Report Template Can be Downloaded from here.

Calibration Report / Certificate

Following information must be present in Pressure Switch Calibration Certificate

1.Unique instrument identifier .Eg: P&ID Tag

2.Mfg,Model,Serial Number,Location

3.Setpoint with units of pressure

4.Reset point (if necessary) or some some way to indicate “trip on increasing input”

5.NO or NC contacts

6.Tolerance with units of measure

7.Test equipment used with unique identifier and next due date

8.As found and As left data

9.Results

10.Technician signature / Date