Flow MeasurementInstrumentation

Differential Pressure flow measurement – How it works ? Advantages and Disadvantages of DP flow measurement

Working Principle of Differential Pressure Flow Measurement

Flow measurements are essential to run a plant efficiently and safely.There are no real flow measurement technologies available including differential pressure flow also known as DP flow which utilizes a variety of measurement instruments.

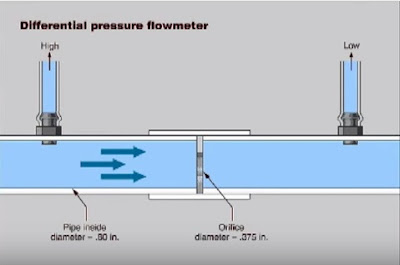

DP flow is measured with the combination a primary element and a secondary elements.

The primary element is placed in the pipe to create a differential pressure and connecting

the secondary element to the process.

The secondary element or transmitter takes measurements from the primary element and converts them into useful quantitative values and transmits those values to a control system.

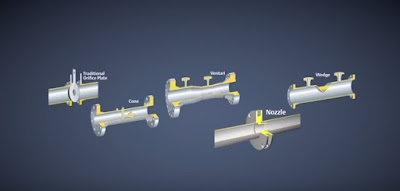

There are many types of primary elements including traditional orifice plate cone venturi nozzle wedge

How to select a differential pressure flow measurement Primary element?

Primary element selection is dependent on process conditions.All these different primary

elements have one thing in common, they constrict the flow in a pipe causing a pressure

drop from one side to the other. the difference in pressures is the differential pressure.

The square root DP is proportional to the flow rate.

Traditionally transmitters were connected to the process with external impulse piping.

Modern DP Flow Transmitters -The impulse piping is built into the primary element this allows the transmitter to be directly mounted to the process line.Advantages of this type of flow transmitters are Easy installation and reduce maintenance cost

Advantages of Modern Differential Pressure Flow Transmitters.

1.Simple technology with no moving part.

2.Compact sensor

3.Configurable for bi-directional flow

4.Usable over a very wide range of sizes

5.Relatively inexpensive

Disadvantages of DP flow measurement.

1.Limited accuracy and turndown range

2.Causes a pressure drop and reduces pipe’s free passage

3.Orifice often a wear-prone point

4.Depends on good pressure sensor practice

5.Changes in liquid characteristics can affect readings.

Related Topics: