What is Well Head Control Panel?

Well Head Control Panel (WHCP) is used to monitor the flowing conditions of the well flowline and to initiate a shutdown of the oil well.

WHCP installed near the wellhead incorporates all that components installed together in WHCP to do as a control function to operate the well.

WHCP insclude components such as:

- Pneumatic components: 3-way pilot valve, 3-way push button, pneumatic pressure switch, pressure regulator etc.

- Hydraulic components: Interface valve (pneumatic to hydraulic), hydraulic pump, hydraulic reservoir tank, PSV etc

- Instrumentations: Pressure gauge, chart recorder (pressure, temperature, and flow rate), pressure switch (PSLL, PSHH), temperature gauge etc.

Functions of WHCP:

The wellhead control system’s function is to monitor the flow line pressure of each well, interface with the Emergency Shutdown System (ESD) facility, and control the surface safety valve (SSV). The well control system also monitors the surface-controlled underground safety valve (SCSSV) for the well when required.

- The main function of WHCP is to shut down the well in case conditions that harm or for other interventions as well as the work test, etc.

- Wellhead Control Panels and Systems control a wellhead platform’s critical process security parameters and provide secure and sequential start-up and shutdown of production wells as per Secure charts model.

- Use the Hydraulic high pressure for sub surface safety valve (sssv)/Down Hole valve/SCSSV.

- Wellhead shutdown systems come with integrated or separate stand-alone or skid-mounted hydraulic power units (HPUs) with interchangeable hydraulic pumps, accumulators and reservoirs, etc.

- We can open or close the DHSV using the push button in the panel with the wellhead control panel. A master valve or wing valve with button push button can also be opened or closed.

Surface Safety Valve (SSV):

The SSV is usually mounted as a wing valve on a Christmas tree with high or low pressure wellhead. This name is derived from the tree-like nature of the branching valves and fittings. To allow maintenance, a manual valve must be mounted between the SSV and the well.

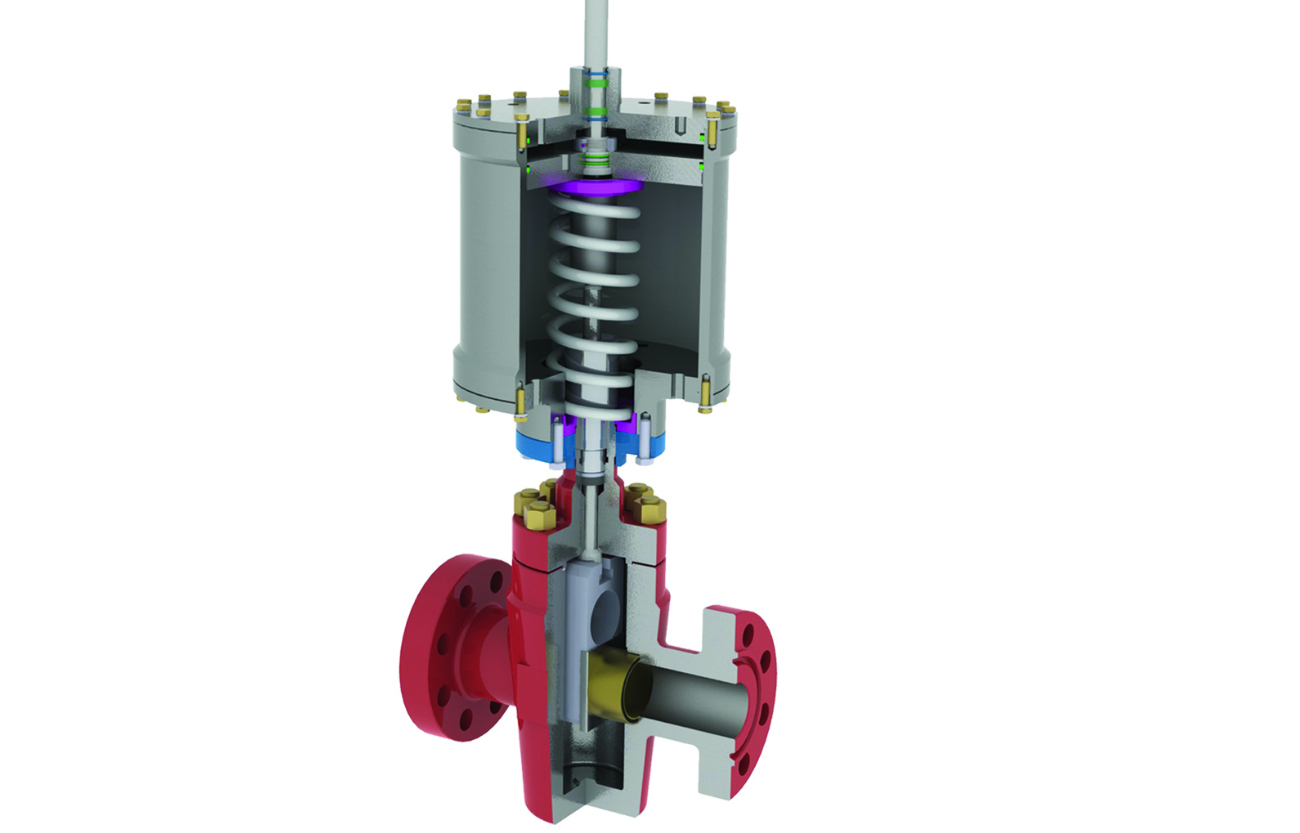

Normally a reverse gate valve is the type of valve used in a shutdown valve flow line. Because of its self-closure, this valve is well suited for this application.

The valve consists of a gate assembly operating through the valve at 90 degrees to the pathway. The stem and gate of the valve rise to be closed. This stem action is opposite to a typical gate valve’s stem action.

An actuator type with a diaphragm or piston is used with a reverse gate valve. Through applying pressure above the diaphragm, which drives down the stem, the valve is opened. To shut the valve, the diaphragm stress is removed. The flowline pressure drives the gate stem upward, closing the valve.

A spring, located under the diaphragm of the actuator, will also close the valve when there is equal pressure on both sides of the valve.

Surface-Controlled Subsurface Safety Valves (SCSSV)

SCSSVs are specially designed wellhead shutdown valves which are kept open by continuous hydraulic pressure maintenance. Typically these valves are hundreds of feet below the seabed or land surface. Occasionally it takes more than one valve per well.

The number of wells that a hydraulic system controls depends on local preference. Sometimes it is preferred to have individual hydraulic systems.

The wells are usually grouped into logical “blocks” that allow good access and control of the operator in case of a problem. Normally, a limit of no more than 10 to 20 wells per hydraulic system will allow resetting of all SCSSVs in less than 5 minutes.

A pneumatically driven pump with a second pump as a backup is supplied with hydraulic pressure. The backup pump can be another pneumatically driven pump with the option of a manual operator or a pump operated by hand.

To monitor the hydraulic pressure and alert the operator, a low-pressure sensor may be installed. On the pump discharge, a relief valve is given to release excess backpressure back into the supply tank.