- What is a feedback control?

- What are the characteristics of feedback?

- How does a feedback control work?

- What are the key components of a feedback control system?

- What are the objectives of the feedback control?

- What are the types of feedback system?

- How do feedback control systems manage disturbances?

- What is the role of stability in feedback control systems?

- What is a Proportional-Integral-Derivative (PID) controller in feedback systems?

- How does feedback improve system performance over time?

- What are the advantages of feedback control?

- What are the disadvantages of a feedback system?

- What is a feed-forward control?

- What are the advantages of the feedforward control?

- What are the disadvantages of a feed forward control?

- What is the difference between feedback and feedforward control?

- Does the feedback and feed-forward can be used in a single process?

- What are real-life examples of feedback control systems?

- What is a feedback control system with an example?

- What is feedback in process control system?

- What is feedback in controlling?

- What is a feedback system and its types?

What is a feedback control?

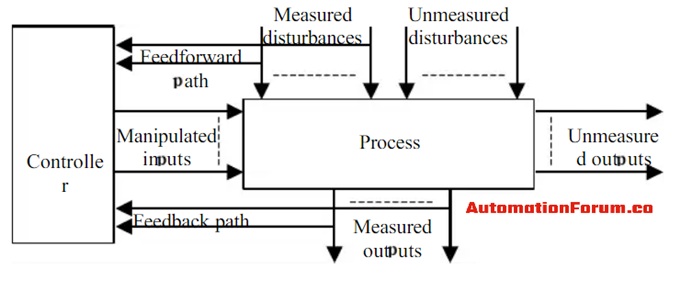

The feedback is an electric signal which is transferred from the output to the controller, so the controller would be able to calculate how the output is different from the required value. The controller would know the past state of the system output with the help of this feedback signal. The controller would calculate the error and it would vary the system input to get the required output. The closed-loop system is also called a feedback system because it fed back the output into the input so that the errors can be cleared and the required output quality can be maintained. The feedback control is to remove the measured disturbances. The feedback controls are automated and it should do the sensing, calculating, and manipulating to be performed by the equipment, and that each element must communicate with the other elements in the control system.

- What is an automatic control system?

- What is a servo valve?

- What is industrial control system (ICS)

- Basic of Quality Assurance (QA)

- What is mimic panel?

- What is Protective system Override ? & What is Protective Override switch (POS)?

- What is Reliability Centered Maintenance (RCM)?

- How a Valve is controlled using a 4-20mA loop

What are the characteristics of feedback?

- Good accuracy

- It has a slight tendency towards oscillation (instability)

- The non-linear effects are reduced

- The effects of external disturbances or noise can be reduced

- The effects of external disturbance and noise are reduced

- Product quality can be increased

- The response to the variation in the input is high

How does a feedback control work?

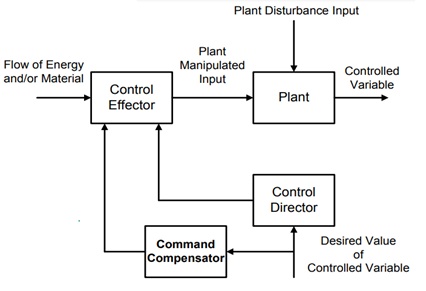

In a control system, a feedback loop is an important tool, the feedback loop will consider the system output and this will help the system to alter its operation in order to get the required output. In order to do this task, a system should have controllers, compensators, and feedback structures to the system. The feedback control system is composed of sensors, controllers, process systems, etc. The major components of a feedback control system are input, the process which is being controlled, output, sensing elements, controllers, and actuating devices. The feedback control would only need minimal knowledge of the process that is to be controlled.

The feedback control can be considered as the easy way to automate the control of a process. The sensors in the control system would measure the actual value of the controlled variable. So after measuring the value it will be transmitted to the feedback controller. The controller would compare the measured value to the desired value and the difference between these values is considered as error. So if there is an error then the controller would send a proportional output to the control value. The controller would send a signal to the plant and sets the process variable, according to the set point. So in case if there is a disturbance that affects the process variable of the plant then the sensor in the feedback section would detect this and sends a signal to the controller.

What are the key components of a feedback control system?

A feedback control system generally consists of the following components:

- Reference Input (Setpoint): The desired or target value of the controlled variable.

- Sensor/Transducer: Measures the actual value of the controlled variable.

- Controller: Compares the measured value with the setpoint and computes the error signal.

- Actuator: Adjusts the system based on the controller’s output to minimize the error.

- Feedback Loop: Returns the system’s output to the controller to ensure that the process is continually adjusted.

What are the objectives of the feedback control?

The major objective of feedback control is to ensure that the output value of the system must be similar to the required value. This is done by tracking the reference trajectories or by maintaining close to their setpoints. The feedback signal would resist the disturbance signal, which affects the output, and also it can improve the performance of the system. The feedback control can also stabilize the unstable plant.

What are the types of feedback system?

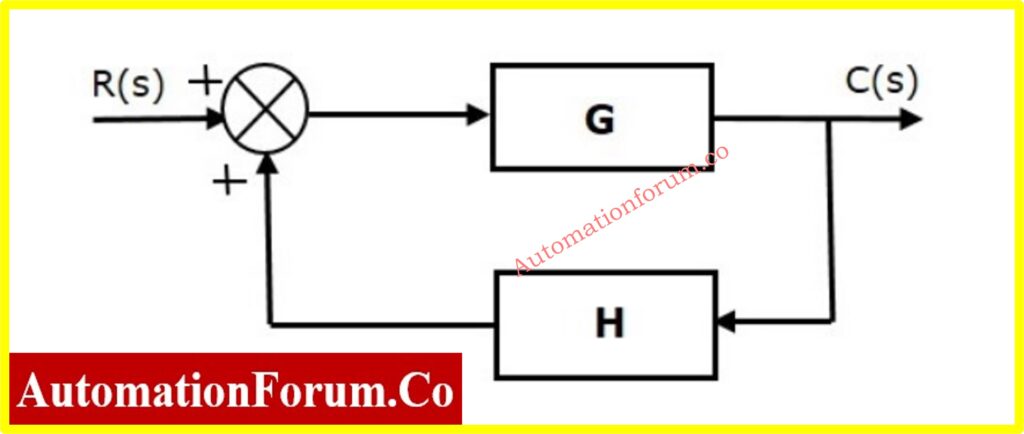

Positive feedback system

In a positive feedback control system, the reference input, R(s)R(s)R(s), is added to the feedback output. The block diagram below illustrates a typical positive feedback control system.

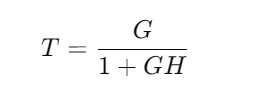

The concept of the transfer function will be discussed in later chapters. For now, consider the transfer function of a positive feedback control system as:

Where:

- T is the transfer function or the overall gain of the positive feedback control system.

- G is the open-loop gain, which is a function of frequency.

- H is the gain of the feedback path, also a function of frequency.

In this type of feedback system, the set-points and the output values are added together by the controller as the feedback in phase with the input. So in this feedback, it would increase the event that caused it, because of this an event that is influenced by the positive feedback would increase or decrease its output activation until it hits a limiting constraint.

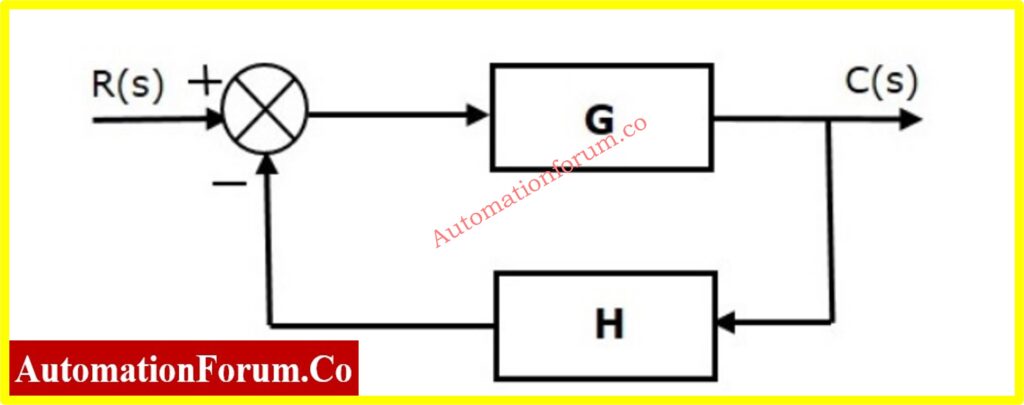

Negative feedback

In a negative feedback control system, the feedback reduces the error between the reference input, R(s)R(s)R(s), and the system output. The block diagram below depicts a typical negative feedback control system.

The transfer function of a negative feedback control system is given by:

Where:

- T is the transfer function or overall gain of the negative feedback control system.

- G is the open-loop gain, which is a function of frequency.

- H is the gain of the feedback path, also a function of frequency.

Negative feedback enhances system stability, improves accuracy, and minimizes errors by counteracting disturbances.

The negative feedback would take place, if the result of the process would affect the operation of the process in a way to reduce the changes. This type of feedback can create stability. This type of feedback is very stable, accurate, and responsive. In this type of feedback control, the output value will be subtracted from the input value (required value). The value that we get is an error and thus we could determine how far the output is varied from the required value. The major advantage of the negative feedback is that it has good accuracy, the system sensitivity to the disturbance is reduced, smoothing and filtering, and high bandwidth.

How do feedback control systems manage disturbances?

Feedback control systems are designed to reject disturbances by continuously monitoring the output and adjusting inputs. When a disturbance affects the system, sensors detect deviations from the setpoint. The controller processes the error (difference between desired and actual output) and alters the actuator’s input to bring the system back to the setpoint, thereby minimizing the effect of the disturbance.

What is the role of stability in feedback control systems?

Stability is a critical aspect of feedback control systems. A stable system will return to its setpoint after a disturbance, while an unstable system may oscillate or diverge from the setpoint. To ensure stability, control systems must be designed with proper feedback mechanisms and tuning of controllers (like PID controllers) to avoid excessive oscillations or drift in output values.

What is a Proportional-Integral-Derivative (PID) controller in feedback systems?

A PID controller is widely used in feedback control systems. It consists of three terms:

- Proportional (P): Responds to the current error by adjusting the output proportionally to the error.

- Integral (I): Addresses accumulated past errors to eliminate steady-state errors over time.

- Derivative (D): Predicts future errors by considering the rate of change of the error, thus improving the system’s response speed and stability.

How does feedback improve system performance over time?

Feedback systems continuously adjust themselves to maintain optimal performance. As external conditions or internal parameters change, feedback allows the system to adapt, correct deviations, and improve accuracy and stability. Over time, with proper design, feedback helps maintain consistency, reduces steady-state error, and optimizes process control.

What are the advantages of feedback control?

- Rejection of disturbances

- The system sensitivity will be very less to the plant uncertainties

- The steady-state error reduction of the system is increased

- The transient response can be easily controlled

- System stability is improved

- The overall system gain is improved

- High bandwidth

- The effect of variation of the system parameters are reduced

- There is no need to know what disturbance will affect the process

- The relation between the process and the final control element is not a problem

What are the disadvantages of a feedback system?

- If the system is not designed properly then there is a possibility for instability

- The feedback inherently couples different art of a system

- The whole feedback process with control system could be complex

- The feedback control won’t take any action till there is a change in the controlled variable

- The feedback control won’t be able to do the predictive control action in order to compensate for the effects of known or measurable disturbances.

- In certain cases, the controlled variable can’t be measured online

- The feedback system can’t handle large time constant or long time delays, in case if there is a large and frequent disturbance then the process would operate continuously at a transient state and it would never achieve the desired state

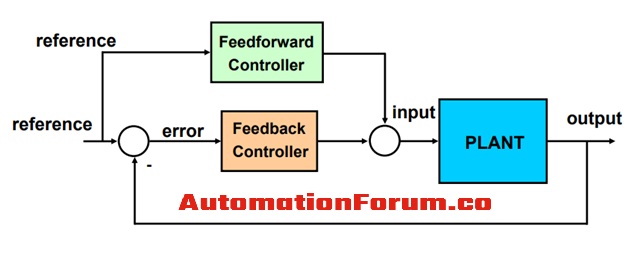

What is a feed-forward control?

The feed-forward control can anticipate the effect of disturbances that could affect the process, this type of control would sense and compensate these problems before it affects the process. This type of control has the limitation that it can’t completely compensate for the disturbance because of the variation and imperfection of the mathematical model and also because of the imperfections in the control action. So basically a feedforward control would measure the important disturbance variables and they would take proper actions before it affects the process. In order to prevent the disturbance in a system before it happens, this system would require to know the plant behavior or the plant model. So if the feedforward system gets a proper plant model then it can prevent the errors before it affects the process.

What are the advantages of the feedforward control?

- It would take proper action in case there is any chance of deviation in the controlled variable so it would act before the error affects the process

- It can act quickly according to the process model

What are the disadvantages of a feed forward control?

- The measurement of the disturbance variable must be done online and for many applications it is not possible

- If the feedforward control needs to operate properly a process model is needed and this is to determine how the control variables are affected by the disturbances. So the performance of the feedforward control is depended on the process model accuracy

What is the difference between feedback and feedforward control?

- The major objective of the feedback system is to reduce error when it happens

- In the feedforward control it would control or reduce the transient response

- The feedback control can compensate for any disturbances that affect the control variable

- In the case of feedforward control, it would compensate the disturbance before it affects the control variable

- The feedback control won’t do anything until there is a deviation in the controller variable, while the feedforward control does take preventive actions.

- The feedforward control takes predictive control action while the feedback control doesn’t

- A feedforward control system has a feedback structure, while the feedback control system doesn’t have a feedforward structure

- The major advantage of the feedback over the feedforward is that the feedback control can detect all the disturbances while the feedforward control can’t do this.

- The feedforward control can’t be used for adaptable, non-linear, or time varied systems but there is no such problem for the feedback control.

- The feedback control only requires minimal knowledge of the process that is to be controlled but the feedforward would need maximum details about the process.

Does the feedback and feed-forward can be used in a single process?

Mostly the feedback and the feedforward are used together in a process. So while combining the feedback and the feedforward system we would get the advantages of both. The feedforward components would provide quick response, and the feedback components do the rest of the response accurately, compensating for errors in the model.

What are real-life examples of feedback control systems?

- Thermostats in HVAC systems: A thermostat continuously measures room temperature (feedback) and adjusts the heating or cooling system to maintain a desired setpoint.

- Cruise control in vehicles: The speed of the vehicle is monitored, and the system adjusts the throttle to maintain the set speed, regardless of inclines or declines.

- Autopilot systems in aircraft: Sensors provide real-time data on altitude, speed, and direction, which is fed back into the system to automatically adjust the flight path and maintain stable flight.

What is a feedback control system with an example?

A feedback control system continuously monitors the output and compares it with the desired setpoint. It adjusts the input to correct any deviations, ensuring the output matches the target.

For example, a thermostat in a heating system is a feedback control system. It measures room temperature (feedback), compares it to the desired temperature, and adjusts the heater to maintain the set temperature.

What is feedback in process control system?

Feedback in a process control system refers to the practice of measuring the actual output of a process and using that data to adjust the input, ensuring that the system achieves its desired performance. The feedback loop helps the system self-correct by minimizing errors between the setpoint and the actual output.

What is feedback in controlling?

Feedback in controlling involves using information from the output of a system or process to influence and adjust its input. This ensures the system maintains its desired performance or setpoint. Feedback allows for real-time adjustments, improving accuracy and stability in controlling processes.

What is a feedback system and its types?

A feedback system is a control system that uses feedback to regulate its behavior. It continuously compares the actual output with the desired setpoint and adjusts the input accordingly. There are two main types of feedback systems:

- Positive Feedback: Amplifies the input signal, potentially leading to instability.

- Negative Feedback: Reduces the difference between the output and the desired value, promoting stability and accuracy.