- Vibration

- Measurement of Vibration

- What is need of monitoring machine vibration?

- Methods to evaluate Vibration Measurement

- What are the different sensors used for Vibration Measurement?

- Accelerometer

- Velocity Transducers

- Displacement Transducer

- List some of the non-accelerometer Contact Vibration Sensors

- Explain Non-Contact Vibration Sensors

Vibration

Oscillating movement around equilibrium position is called as vibration. Vibration measurement is used to check electric motors, turbines or bearings health and resonance. The dynamics of the machine, such as the alignment and balance of the spinning elements, are what cause vibrations in all rotating machines. Monitoring vibration amplitude at specific frequencies can reveal shaft alignment and balance, bearing and gear quality, and machine resonance.

Measurement of Vibration

- Vibration analysis is used to determine the functioning and mechanical condition of equipment.

- Vibration measurement is an effective, non-intrusive approach to monitor machine condition during start-ups, shutdowns, and normal operation.

- Vibration analysis is mostly utilized on rotating equipment such steam and gas turbines, pumps, motors, compressors, paper machines, rolling mills, machine tools, and gear boxes.

- Vibration analysis can detect growing problems before they generate unplanned downtime.

What is need of monitoring machine vibration?

- Vibration monitoring can detect failing bearings, mechanical looseness, and worn gears.

- Vibration analysis can detect misalignment and unbalance before bearing or shaft breakdown.

- Vibration levels can reveal incorrect bearing installation and replacement, shaft alignment, and rotor balancing.

Methods to evaluate Vibration Measurement

Vibration characteristics of any dynamic system is analyzed using, three parameters:

- Measurements of acceleration

- Vibration Velocity

- Measurements of displacement

What are the different sensors used for Vibration Measurement?

- Acceleration Sensor – Piezoelectric Accelerometer, Capacitive MEMS Accelerometer

- Velocity Sensor- Velocity pick up, Electro-magnetic Velocity transducer, Laser Velocimeter

- Displacement Sensor – Capacitance type, Inductance Type, Vibration pickup, Laser Displacement Sensor, Eddy current or capacitive displacement sensor

Most contemporary vibration measures use acceleration. Acceleration data once integration gives velocity and double integration gives displacement. Accelerometer signal conditioners have integrators.

Accelerometer

- Accelerometers measure a structure’s vibration or acceleration of motion. It is mainly used in the high frequency vibration and measured in msec2. The piezoelectric material when pressed by the mass due to the force of vibration or a change in velocity (acceleration), produce an electrical charge that is proportional to the force applied to it. Since the mass is constant and the charge is proportional to the force, the charge must likewise be proportional to the acceleration.

Piezoelectric accelerometers

- Piezoelectric accelerometers are good for vibration measurement, however low frequency applications require high sensitivity accelerometers.

- Peizo electric accelerometers rely on the piezoelectric effect of quartz or ceramic crystals to provide electrical output proportional to applied acceleration. For industrial applications, piezoelectric accelerometers are the most common and widely used.

- Its lead zirconatetitanate (PZT) sensor elements generate electric charge or output when accelerated.

- Piezoelectric accelerometers are used for shock testing and vibration measurement.

- Because they are based on strain gauges, they need amplifiers and temperature adjustment, although they have a wide bandwidth (from 0 to 1000 hertz) and low noise.

- Gas or fluid damping protects the accelerometer and keeps it from resonating.

Capacitive MEMS (micro-electro-mechanical systems) accelerometers

- They are the smallest and cheapest.

- These are preferred as they can be placed directly to printed circuit boards.

- Although their low cost and small size have made them popular, their data quality is poor, especially at higher frequencies and amplitudes.

- Their low cost and power consumption make them suitable for health monitoring.

Velocity Transducers

- The velocity pickup is a typical transducer or sensor for detecting rotating machinery vibration. This vibration transducer installs quickly and costs less than others.

- For these two reasons, this sort of transducer is appropriate for broad purpose machine applications.

- Velocity pickups have been employed as vibration transducers on rotating machinery for a very long time, and they are still used for a number of applications today.

Velocity Pick up

- When a coil of wire is moved through a magnetic field, a voltage is induced between the coil’s end wires.

- The induced voltage is created by energy transfer from the magnet’s flux field to the wire coil.

- As the coil vibrates via the magnetic field, a voltage signal is produced.

- The velocity pickup generates vibration signals without external devices.

- Gravity forces affect velocity transducers.

- Because of this, velocity sensors have a sensitive axis. Cross-axis vibration can harm velocity sensors. In instances when induced electrical noise is an issue, the higher output sensitivity is helpful. The greater signal for a given vibration intensity will be less affected by noise.

- Velocity pickups’ frequency responses vary by manufacturer. Most pickups respond between 10 and 1000 Hz.

- When choosing a velocity pickup for a rotating machine application, this is crucial.

- The pickup’s frequency response should be within the machine’s expected vibration frequencies.

- A velocity transducer has internal moving parts, hence it is less popular in hostile areas where better ruggedness is required.

Velocity of Vibration

Velocity of vibration focuses on low and high frequency vibrations. It best represents vibration energy in mm/sec. Mainly measured in true RMS value.

Velocity measurement methods

1. Use of Transducers

Electromagnetic Linear Velocity Transducers

- Usually used to measure oscillatory velocity.

- An EMF is generated in a coil winding by a moving permanent magnet.

- The speed of the magnet’s oscillation determines this EMF.

- This permanent magnet can measure the vibrating object’s velocity.

Electromagnetic tachometer generators

- Measures the angular velocity of vibrating objects.

- They output voltage/frequency proportional to angular velocity.

- DC tachometers employ a permanent magnet or magneto, while AC tachometers use a variable coupling transformer with a coupling coefficient proportional to rotor speed.

2. Laser Vibrometers or Laser Velocimeters

- These novel instruments are sensitive and accurate.

- They use a frequency-modulated (44 MHz) laser beam reflected from a vibrating surface.

- The velocity of the vibrating surface is determined by comparing the reflected beam to the original beam and using the Doppler frequency shift.

3. Acceleration Integration

Similarly with displacement measurements, low-cost digital signal processing makes it practicable to use sturdy, reliable, adaptable accelerometers as sensors and integrate their output to produce a velocity signal.

Displacement Transducer

- One of the measurements to examine the intensity of the vibrations is amplitude, which highlights low frequency vibrations.

- Depending on the signal that we are detecting, the displacement is measured in three ways: peak to peak, zero to peak, and RMS.

- Measurements of displacement are made in three directions: axial, horizontal, and vertical.

- The energy of the vibration is determined by how quickly it repeats in addition to how much movement (displacement) there is (frequency).

- It is measured in microns.

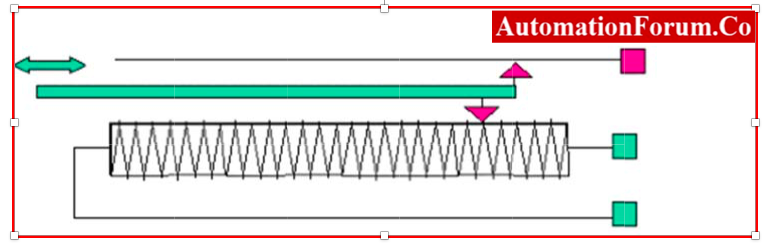

The displacement transducer has a fixed and mobile portion. Although the fixed part serves as a reference, the mobile part is attached to the breaker’s mobile contact and moves with the contacts. The internals of many types of rotating machinery have a number of quite small anular radial clearance gaps between the rotor and the stator, e.g., annular seals, balance drums, and blade-tip clearances. Excessive rotor vibration might cause rubbing or hitting. Accelerometers and velocity transducers measure machine vibration, not rotor motion.

Types of Displacement Transducer used in Vibration measurement

Vibration Pick up

A vibration pickup is a transducer used in conjunction with another instrument to monitor vibrations. Seismic instruments are the most popular vibration pickups. A seismic instrument comprises of a mass-spring-damper system installed on the vibrating body. The displacement of the mass in relation to the mounting base is then used to calculate the vibratory motion.

Capacitance type Displacement Transducer

The capacitance-type displacement transducer operates on the basis of sensing the electrical capacitance of the space between the transducer tip and the target whose position is being measured. The capacitance method is ideal for extremely accurate laboratory measurements, but its great sensitivity to material changes (like oil) or impurities within the clearance gap would make it a difficult in calibration for industrial applications.

Inductance Type displacement transducer

Techniques for measuring displacement

Optical Techniques

- When displacements are sufficiently large, typically >0.1 in., to make stroboscopic photography and strobe lights useful.

- It is possible to determine how far away a light beam is from the source by observing how its intensity or angle changes as it is projected onto a reflected surface.

- Changes in distance can also be observed if the detecting device is quick enough.

- The laser interferometer is the optical measurement tool with the highest sensitivity, accuracy, and precision for measuring distance or displacement.

- A reflected laser beam is combined with the initial incident beam using this equipment.

- Phase differences create interference patterns that can quantify displacement down to 100 nm..

- Contact Techniques: Several relative motion sensors measure relative motion or the distance between two objects by making direct touch with them. They include linear potentiometers, cable position transducers (string-pots), and LVDTs. All of these gadgets rely on electromechanical transducers and mechanical linkages.

- Double Integration of Acceleration: Many applications are adopting the more durable and adaptable accelerometers as sensors and double integrating the acceleration signal to derive displacements as a result of the expanding availability and falling cost of digital signal processing. Digital processing can produce results that are quite high-quality and high-accurate, whereas older analogue integration approaches tended to be noisy and imprecise.

List some of the non-accelerometer Contact Vibration Sensors

Electromagnetic velocity sensors

- More difficult to get, electromagnetic velocity sensors have the advantages of sensing velocity directly and having a wide operating temperature range.

- They work by utilising the current produced by a magnet moving inside a coil.

Gyroscopes or Angular Rate Sensors

- Gyroscopes measure angular rate as opposed to accelerometers, which measure linear acceleration.

- Instead of an output represented in g’s, the gyroscope’s output is a rate value, commonly displayed as degrees per second (°/s).

- An accelerometer cannot give a frame of reference like that offered by gyroscopes (or even a bunch of accelerometers).

- Accelerometers can help offer a frame of reference in regard to gravity because they monitor inertial forces, but it becomes challenging to retain that reference when the accelerometer is vibrating as well.

- By experiencing persistent static accelerations that could be mistaken for the gravity vector, an accelerometer may become “disoriented.”

- The system can, however, determine the true direction of motion thanks to the gyroscope.

- Gyroscopes, when combined with accelerometers, aid in maintaining the system’s orientation.

- Gyroscopes are typically used in conjunction with accelerometers to monitor vibration, but when used alone, they provide a far less complete image of the vibrating environment.

Explain Non-Contact Vibration Sensors

Microphone

- A microphone or an acoustic pressure sensor can be used to monitor high-frequency vibration in a cost-effective manner. Microphones are particularly helpful for tracking how a system’s vibration varies over time.

- Applications for health monitoring can profit substantially from the low cost and ease of use of a microphone. The frequency content of a vibration can also be represented very clearly and precisely using microphones.

Laser displacement sensor

- Laser displacement sensors employ triangulation with a transmitting and receiving lens.

- Using a transmitting lens, a laser beam is directed at the target.

- The light is then reflected back towards the sensor and focused on a receiving element by a receiver lens.

- The angle of the reflected light changes as the target travels nearer and farther away (it is focused on a different place on the receiving element).

- When using spinning components or where the bulk of the accelerometer would have an excessive impact on the system’s motion, displacement sensors are preferred.

Eddy current or capacitive displacement sensors

- These have similar benefits and drawbacks as lasers when it comes to measuring vibration.

- They provide a method to “measure vibration through the air” without changing the vibrating system, but they are only able to access relative motion; as a result, they must remain stationary and measure the difference in motion of a nearby structure.