There are different types of boilers classified based on their boiling process. These are

Fire Tube Boiler:

In a fire tube boiler, hot gas passes through the pipes and boiler feed water is inside the shell to be converted into steam. Fire tube boilers are usually used for relatively small steam capacities with low to moderate steam pressures.

As a guideline, competitive fire tube boilers for steam speeds up to 12,000 kg / hour with pressures up to 18 kg / cm2. Fire tube boilers can use fuel oil, gas or solid fuel in their operations.

Working:

The ignition process occurs in the pipe, then the heat generated is delivered directly into the boiler containing water. The size and construction of the boiler affect the capacity and pressure produced by the boiler.

Characteristics:

- Usually used for relatively small steam capacity (12,000

kg / hour ) with low to moderate pressure (18 kg / cm2). - In its

operation it can use fuel oil, gas or solid fuel. - For economical reasons, most fire tube boilers are constructed as boiler packages (assembled by the factory) for all fuels

What are burners used in boilers? types of burners

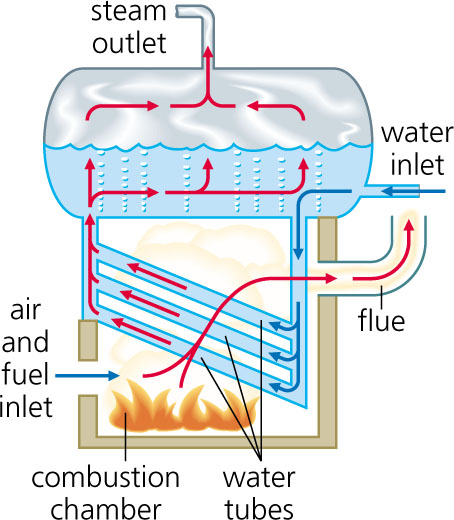

Water tube boilers:

In the water tube boiler, boiler feed water flows through the pipes into the drum. The circulated water is heated by the combustion gas to form steam in the steam area in the drum.

This boiler is chosen if the steam demand and steam pressure are very high as in the case of a boiler for power plants

A very modern water tube boiler designed with a steam capacity between 4,500-12,000 kg / hour, with very high pressure.

Working of water tube boiler

The ignition process occurs outside the pipe. The heat produced is used to heat a pipe containing water. The feed water was previously conditioned first through an economizer.

The resulting steam is then collected first in a steam drum until it is appropriate. After going through the secondary superheater and primary superheater stages, steam is released into the main distribution pipe.

Characteristics of water tube boiler:

- Forced, induced and balanced drafts help to improve combustion efficiency

- Less tolerant of the quality of water produced

from a water treatment plant. So that water must be conditioned on minerals and other substances that are soluble in water - Allows for higher levels of heat efficiency

- This boiler is used for the needs of very high steam pressures such as in power plants.

- Steam capacity between 4,500-12,000

kg / hour with very high pressure. - Using oil and gas fuel for boiler water tubes assembled from the factory

- Using solid fuel for boiler water tubes that are not assembled at the factory.

Combination boilers:

It is called a boiler combination because it is available as a complete package. When sent to the factory, it only requires steam pipes, water pipes, fuel supply and electricity connections to operate. Boiler packages are usually

Characteristics of Combination boilers:

- The small amount of combustion space and the high heat released results in faster evaporation.

- The large number of small diameter pipes makes it have good convective heat transfer.

-

Forced Forced or induced draft systems produce good combustion efficiency. - A number of

passes / passes produce better overall heat transfer. - Higher thermal efficiency compared to other boilers.