3 – Way Valve Manifold Essential Component for DP Transmitters

The 3-valve manifold serves as an essential component alongside Differential Pressure (DP) Transmitters to measure pressure with precision and ensure operational safety. It consists of three manual valves:

- Two Block Valves – High-Pressure (HP) and Low-Pressure (LP) Block Valves

- One Equalizing Valve – Used to balance pressure between the transmitter ports

The main functions of this manifold include:

- Isolating the DP transmitter for maintenance and calibration.

- Preventing over-ranging (overloading) of the DP transmitter.

- Allowing proper venting or bleeding of trapped air from the transmitter tubing..

- Ensuring safe startup and shutdown procedures for Dp transmitter.

The following procedures provides how to bring the DP transmitter into service and safely remove

Refer the below link for the Step by Step Calibration Procedure for Differential Pressure Transmitter

Bringing a DP Transmitter with a 3-way Valve Manifold into Service

When commissioning a new or serviced DP transmitter or returning it to service after maintenance, follow these steps:

Step 1: Ensure All Valves are Initially Closed

- Confirm that the HP Block Valve, LP Block Valve, and Equalizing Valve are all in the closed position.

- This prevents any immediate pressure from being applied to the transmitter.

Click here for What is manifold and types of manifolds and application of manifolds in Instrumentation?

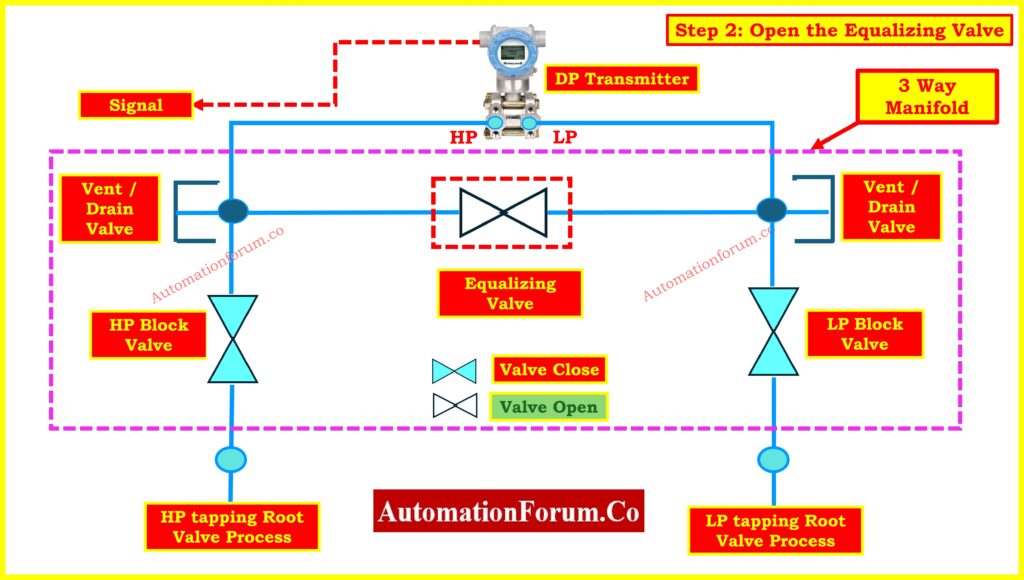

Step 2: Open the Equalizing Valve

- The Equalizing Valve (center valve) should be opened slowly.

- This allows equal pressure to reach both the HP and LP sides of the DP transmitter.

- This step ensures the transmitter starts at zero differential pressure, preventing potential damage from a sudden pressure surge.

Click here for Differential Pressure Transmitter Commissioning Checklist for Flow Measurement Applications

Step 3: Slowly Open the HP Block Valve

- Gradually open the HP Block Valve to introduce high-pressure fluid to the transmitter.

- Observe for any leaks around the valve connections.

Step 4: Close the Equalizing Valve

- Once the HP pressure has stabilized, close the Equalizing Valve to separate the HP and LP sides.

- This allows the DP transmitter to start detecting pressure differences accurately.

Step 5: Open the LP Block Valve

- Now, slowly open the LP Block Valve to allow low-pressure (LP) fluid to enter the transmitter.

- At this point, the transmitter is measuring the actual differential pressure (HP – LP).

Step 6: Open the Main Root Valves

- Finally, open the LP and HP tapping root valves to allow the process fluid to flow freely from the tapping points into the transmitter.

- The DP transmitter is now fully operational and transmitting a pressure signal.

Step 7: Bleeding Air from the System (If Required)

- If any air is trapped inside the DP transmitter, use the Vent/Drain Valves to bleed the air.

- This ensures accurate pressure measurement without air pockets affecting measurement readings.

Click here for Transmitter Calibration Span, LRV and URV Value Calculator from Measured 4 to 20 mA

Removing a DP Transmitter with a 3-way Valve Manifold from Service

When maintenance, calibration, or replacement of the DP transmitter is needed, follow this safe removal process:

Step 1: Close the Main Root Valves

- Shut off the HP and LP tapping root valves to stop the flow of process fluid to the manifold.

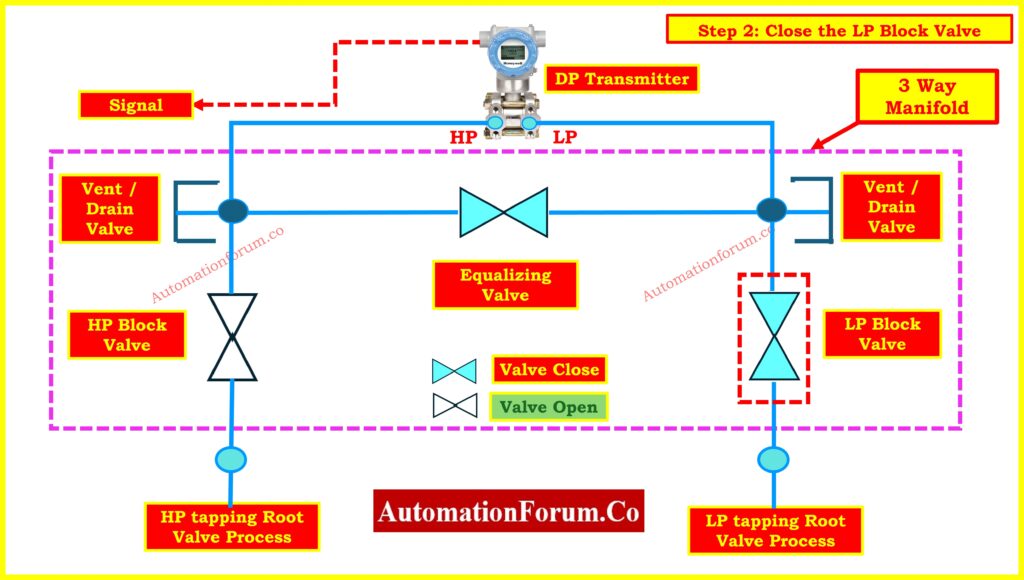

Step 2: Close the LP Block Valve

- Close the LP Block Valve to isolate the low-pressure side from the transmitter.

Step 3: Open the Equalizing Valve

- Opening the Equalizing Valve allows equal pressure to build on both sides, preventing a pressure differential that could damage the transmitter.

Step 4: Close the HP Block Valve

- Close the HP Block Valve to isolate the high-pressure side from the transmitter.

Step 5: Bleed any Residual Pressure

- If there is residual pressure left inside the DP transmitter, use the Vent/Drain Valves to release it.

- This ensures the transmitter is completely depressurized before disassembly.

At this point, the DP transmitter is safely out of service, ready for maintenance or calibration.

Following the correct procedures when bringing a DP transmitter into service or removing it ensures safe and accurate operation. The 3-way valve manifold plays a important role in protecting the DP transmitter from sudden pressure changes and allowing for controlled pressure equalization.

By carefully following the valve operation sequence, you can:

- Prevent pressure surges that may damage the transmitter

- Ensure accurate differential pressure readings

- Facilitate easy maintenance and calibration

- Maintain a safe working environment

Click here for How to Safely Zero a DP Transmitter with 3-Way Valve and 5-Way Valve Manifolds ?

Procedure for Bleeding the DP Transmitter

- Ensure the HP and LP Block Valves are open (transmitter is in operation).

- Keep the Equalizing Valve closed to maintain proper differential pressure.

- Open the Vent/Drain Valves (as shown in the diagram) one at a time to release trapped air or liquid.

- Once bleeding is complete, close the Vent/Drain Valves securely.

Note

- The Equalizing Valve connects the high-pressure (HP) and low-pressure (LP) sides of the transmitter.

- If it is open during bleeding, it will equalize pressure between HP and LP, preventing proper venting of trapped air or fluid.

Click here for Key Considerations for Pressure Transmitter Manifold Selection