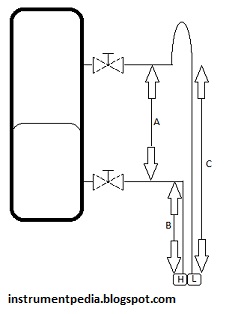

How to calibrate Dp level transmitter for low side dry leg

Differential level transmitter for low side dry leg

Calibration Procedure:

*Hook up HART Communicator and verify some parameters by refer to data sheet. Typical parameters are, tag number, PV, LRV and URV.

*Isolate the instrument from the process.

*Remove connection at manifold to the process after release the process pressure

*Connect pressure calibrator to high side of manifold

*Expose the low side to atmosphere

*Hook up a multimeter in series with the signal to the DCS to measure current signal.

*Apply pressure as per data sheet LRV

Multimeter should show 4mA

If not, do zero adjustment at transmitter using HART Communicator

*Apply pressure as per data sheet URV

Multimeter should show 20mA

If not, do span adjustment at transmitter using HART Communicator

*Verify the linearity by increasing and decreasing the pressure (0%,25%,50%,75%,100%,75%,50%,25% and 0%of range)

Note

LRV and URV range from data sheet should include the pressure effect from bottom flange height to the transmitter and the SG of process liquid.

Example calculation

S.G=0.89

A= 2000mm (measurement length)

B= 100mm (off set)

C=A+B=2100mm

Dp = pressure at high side – pressure at low side

LRV = (B x S.G) – pressure at low side

= (100mm x 0.89) – 0

= 89 mmH2O

URV = (C x S.G) – pressure at low side

= (2100mm x 0.89) – 0

= 1869 mmH2O

Related posts:

Displacer level transmitter calibration and installation consideration

Capillary type DP level transmitter

Flow transmitter pitot type calculation and calibration

DP Flow transmitter calculation and calibration.