- What is Instrumentation & Control?

- What are the different classes in Measuring instruments?

- Explain the block diagram of basic Instrumentation control

- What is Instrumentation and Control Engineering?

- What does Instrumentation and Control Engineer do?

- What are the terminologies in Instrumentation and Control Engineering?

- What are the Instruments Used in Instrumentation and Control engineering?

- Instrumentation and Control Engineering, and its Industrial application in various fields

- Aerospace Industries:

- Biomedical Instrumentation:

- List process control instrumentation used in various industries

- Few examples of instrumentation & process control industries

- What is meant by measurement?

- Controller

- Value of Instrumentation Engineer

- What being an Instrumentation Engineer means?

- Role of Instrumentation technologists and mechanics?

- What is Industrial Instrumentation & control?

- Why do we need/use Instrumentation & control?

- The Role of Control & Instrumentation Engineer

- The Role of Design Engineer in Instrumentation & Control

- Why is Instrumentation & Process control essential?

- Define Instrumentation as per ISA.

- Modern Automation World

What is Instrumentation & Control?

Instrumentation is defined as measurement and control of process variables within a production, or manufacturing area.

In other words, instrumentation & control is one that deals with automated measurements that controls the physical quantities like pressure, level, temperature, flow etc.

What are the different classes in Measuring instruments?

- Monitoring of processes and operations

- Control of processes and operations

- Experimental engineering analysis

Explain the block diagram of basic Instrumentation control

The most important in instrumentation & control is measurement. After measuring a quantity from process, the measured value is send to indicating or computing device

From this value either manual or computing action takes place. If controlling action is automated, the computer sends the signal to final control elements which then influence the quantity being measured.

This final control elements can be control valve, electric heater, electric motor. Both the Measuring device & Final control device are connected to same process.

For direct control other instruments, this signal can also be sent to a programmable logic controller (PLC), Distributed Control System (DCS), Supervisory Control and Data Acquisition (SCADA), or other computerized controller, where it will be converted into human-readable values and used to control the system’s devices and processes.

What is Instrumentation and Control Engineering?

The field of “instrumentation engineering” focuses on the theory and use of measuring instruments that are used in the design and configuration of automated systems. It also deals with the control and measurement of various variables such as flow, temperature, pressure, and others.

The subjects range from pneumatics and hydraulics to thermodynamics in mechanical, electrical drives and power electronics in electrical, microprocessors and microcontrollers in electronics, data structures in computer networks, and fundamentals of instrumentation such as robotics, soft computing, and sensors.

What does Instrumentation and Control Engineer do?

Instrumentation engineers often work for industries with automated processes with the aim of enhancing the productivity, dependability, safety, optimization, and stability.

Integrating the sensors with the transmitters, controls, and systems is frequently the responsibility of instrumentation engineers. They are in charge of system calibration and maintenance, as well as design or specify installation, wiring, and signal conditioning.

What are the terminologies in Instrumentation and Control Engineering?

| Measured Variable | Range ability or turndown |

| Measured Signal | Repeatability |

| Input signal | Accuracy |

| Output signal | Hysteresis |

| Range | Dead time. |

| Span | Dead band |

| Suppressed zero | Elevated zero |

Click here to know more about Instrumentation terminology.

What are the Instruments Used in Instrumentation and Control engineering?

Below mentioned are few examples of instruments used in Instrumentation field

Temperature indicators

Temperature indicators are installation elements that can interpret and display signals from temperature sensors. Temperature indications make it simple and affordable to value resistance sensors.

Flow meter

A flow meter is a device used to measure the flow rate or quantity of a gas or liquid moving through a pipe. Flow measurement applications are very diverse and each situation has its own constraints and engineering requirements.

Level sensors

It is one of the widely used sensing element for figuring out how much fluid, liquid, or other substance is stored in an open or closed system.

Types of level measurement

- Continuous level measurement

- spot level measurements

When measuring levels up to a defined limit, continuous levelsensors produce precise data. Only the liquid level’s high or low state is indicated by point level sensors. The level sensors can convey their findings to a monitoring system by connecting them to an output device. Wireless data transfer to the monitoring system is a feature of modern technologies, and it works well in elevated and dangerous sites that are challenging for regular workers to access.

Pressure regulator

A pressure regulator is a device that is used to control the pressure of a fluid or gas in a system. It consists of a valve that is designed to open or close in response to changes in the pressure of the fluid or gas, allowing the flow rate to be maintained in a constant pressure.

Pressure sensor

Pressure sensor is a device that detects pressure and transforms it into an electric signal, the strength of which is dependent on the pressure being applied.

Pressure Switch

Pressure switch is a type of switch that shuts off electricity when a predetermined fluid pressure is attained at its input. Depending on the switch’s design, contact could be made when pressure rises or falls. Pressure switches are frequently used in industry to automatically monitor and manage pressurized fluid-using systems.

Instrumentation and Control Engineering, and its Industrial application in various fields

- Aerospace Industries.

- Biomedical Industries.

- Nuclear Industries.

- Oil and gas industries.

Aerospace Industries:

Aircraft

Avionic System

Inertial navigation system

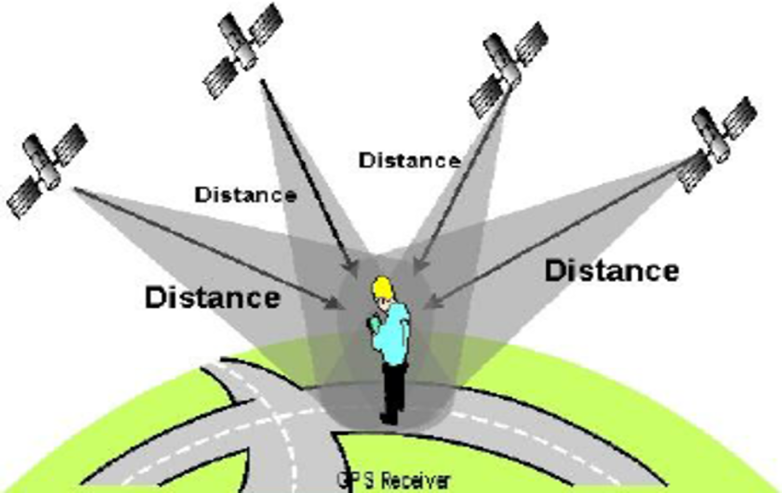

Global Positioning System

Weather Radar

Aircraft equipped with airborne weather radar are equipped with a useful instrument for avoiding hazardous clouds such as CBS (Columbia Broadcasting System). It is something that has been thought of and developed in order to detect the location of active and substantial cloud cells as well as the strength of their presence in order to offer the pilot with information that will help them to avoid them. But in order for pilots to successfully use weather radar to keep them out of trouble, they need to have a basic understanding of how weather radar works, how to use the technology, and how to interpret the information and display. Only then will they be able to use weather radar successfully.

The flight data recorder (FDR) is a device that records dozens of parameters that are collected multiple times per second in order to retain the recent history of the flight. The recent history of the noises in the cockpit, including the pilots’ conversations, is recorded by the cockpit voice recorder (CVR). To aid in any future investigations, the two recorders provide exact testimony on the flight history of the aircraft.

Head-up display

Any transparent display that conveys information without having viewers to shift their regular angles of view is referred to as a HUD. The name was given because a pilot could read information with his or her head up and facing forward rather than inclined down to look at lower instruments. Another benefit of a HUD is that it eliminates the need for the pilot to refocus their vision after gazing at optically closer equipment in order to see the outside world. HUDs are currently utilized in commercial aeroplanes, automobiles, and other (mainly professional) applications despite being first created for military aviation.

Biomedical Instrumentation:

Ultra-Sonography

Ultrasonography is a diagnostic medical technique that employs sound waves to generate images on a screen, enabling medical professionals to see inside body components.

Thermograph

An instrument that provides a daily or weekly temperature record in real time. Two metals with different coefficients of expansion are used in the device’s helical strip. The coil then opens and closes, operating a pen that draws a line across a calibrated chart on a circular clock drum.

Radiograph

It is essentially a photographic recording made when radiation passes through a subject and deposits what is known as a latent picture of the subject onto a film.

Endoscope

An endoscope is a lit optical, often thin and tubular tool (a form of borescope) used in endoscopic operations to examine deeply inside the body.

List process control instrumentation used in various industries

- Level Control & Monitoring

- Pressure Control & Monitoring

- Automated Control Systems

- Temperature Control & Monitoring

- Supervisory Control & Data Acquisition (SCADA)

Few examples of instrumentation & process control industries

- Power Plant

- Oil & Gas Refineries

- Petrochemical

- Wastewater Treatment Plant

- Food &Beverage

- Manufacturing industries (Paper, Iron and Steel, etc..)

What is meant by measurement?

Measuring various parameter using instruments in industries for monitoring and control is referred as measurement.

The various parameters are

- Pressure, either differential or static,

- Flow

- Temperature

- Levels of liquids, Density, Viscosity

- Other mechanical properties of materials

- Properties of ionizing radiation

- Voltage, Current, Frequency, Inductance, Capacitance and Resistivity

- Chemical composition & Chemical properties

- Properties of light

- Vibration

- Weight

Controller

After measuring the variable, it is responsible to alter the values of certain field parameters. Such necessary modification can be done using Controller.

Value of Instrumentation Engineer

An instrumentation engineer is responsible for developing system concepts, designing and describing those concepts, maintaining and debugging the system, and resolving any problems that may develop. Government regulation has caused safety precautions to take precedence above increased output or higher profits.

What being an Instrumentation Engineer means?

The instrumentation engineer should help the process to obtain maximum output from the industries with minimum usage of raw materials.

Role of Instrumentation technologists and mechanics?

Technologist and mechanics are those specialized in industrial instrumentation. They are responsible for the repair, maintenance, calibration, adjustment, and installation of the dials, sensors, and other equipment that measures and controls machinery in industrial and commercial plants

What is Industrial Instrumentation & control?

Measurement, analysis, and control of industrial process variables are referred to as industrial instrumentation and control.

Why do we need/use Instrumentation & control?

All manufacturing and industrial processes revolve around instrumentation and process control. Within a manufacturing facility, all operations need to be supervised and managed to ensure that they are carried out in a way that is both efficient and secure.

The Role of Control & Instrumentation Engineer

Engineers specializing in control and instrumentation are responsible for overseeing these systems in manufacturing and processing plants. The primary duties of a control and instrumentation engineer in a manufacturing industry include the planning, creation, and maintenance of various control devices and systems.

The Role of Design Engineer in Instrumentation & Control

The Role of Design Engineer in Instrumentation & Control is to design and develop new devices and enhance or redesign older devices used to control electronic or mechanical systems.

Why is Instrumentation & Process control essential?

All manufacturing and industrial processes revolve around instrumentation and control of the underlying processes. Everything that goes on within a factory must be properly monitored and managed to ensure that it follows the prescribed, most efficient, and safest course of action.

Define Instrumentation as per ISA.

According to Instrumentation and Systems Automation Society(ISA) the definition of Instrumentation (as per Reference: ISA std. S 51.1) is a collection of Instrumentsand their application for the purpose of observation, Measurement, and Control.

Modern Automation World

The Automation means self-directing or decision taken by itself.The development of the digital computer, enhanced data storage and programming tools, advancements in sensor technology, and the formulation of a mathematical theory of control. The field of automation technology control has benefited greatly from all of these advancements. PLCs, DCS, SCADA, etc., are all examples of automation devices, and among the technologies available today are a number of forms of industrial communication systems.

The measurement tools that are available for use as parts of automatic feedback control systems. one of these tools include high sensitivity electromechanical probes, scanning laser beams, electrical field techniques, and machine vision. Computer technology is required to implement some of these sensor systems.