What is Alternator?

A machine that transforms mechanical energy into electrical energy in the form of alternating current at a particular voltage and frequency is referred to as an alternator. Synchronous generators are another name for alternators.

The only form of energy that is converted is an alternating current. Most alternators use a spinning magnetic field along with a stationary armature in order to make it simple and affordable. Depending on the needs of the location, a fixed magnetic field can also be employed with a linear alternator or rotating armature. For instance, an alternator can also be used to refer to an AC electrical generator since this term is typically used to describe a tiny rotating equipment powered by an internal combustion engine.

An alternator is a generator that supplies power to the vehicle and recharges the battery. All cars with a regular internal combustion engine will have an alternator, with the exception of some hybrid versions. A belt usually runs around the alternator, which is typically located to the front of the engine.

Since alternators use electromagnetic to generate electricity, they acquire their name from the term “alternating current” (AC). The interaction between the stator and rotor creates through electromagnetic.

Major Parts of Alternator:

The parts of an alternator and their purposes are listed below:

Stator:

An iron ring called a stator has multiple wire coils twisted around it. When a magnetic field is created, the portion of the stator that serves as the alternator’s body produces an electrical current.

Rotor:

The alternator’s rotor, which rotates the pulley and powers the belt system, is a moving component inside the alternator. It functions as an electromagnet that spins.

Voltage Regulator:

A component that regulates how much power comes from the alternator to the battery is the voltage regulator. As it is built with a variety of functions and operates according to their applications, it regulates the charging process.

Rectifier:

During the charging process, the rectifier is utilised to convert direct current (DC) from alternating current (AC) output.

Slip Rings:

Direct current can be obtained and used to power the rotor through the slip rings.

Slip Ring End and Drive End Bearings:

The purpose of alternator bearings is to support the rotor shaft’s rotation. Additionally supporting the rotor shaft’s rotation are the driving end bearings.

Pulley:

The pulley is a component that is joined to the drive belt system and rotor shaft. Even though the drive belt transfers the engine’s spin to the pulley. The charging process is spurred on by rotation.

Cooling Fan:

In order to preserve the machine’s efficient operation, the heat that alternators produce must be cooled after a predetermined amount of time. These fans are constructed with vents and an aluminium body to effectively dissipate heat. For further cooling, these are also fitted with revolving fans. The most recent kinds of alternators include internal cooling fans, while earlier ones had exterior fan blades.

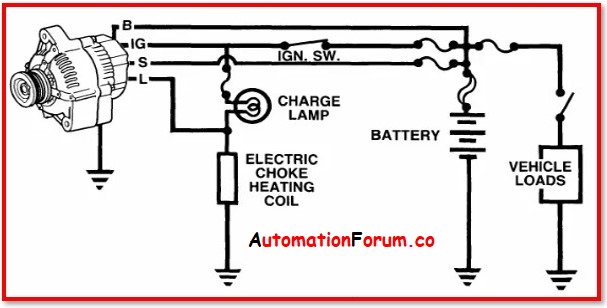

The back of an alternator has a number of terminals or connection points for a variety of purposes:

- IG Terminal – is the voltage regulator that activates the ignition switch.

- S Terminal – is a connector that detects the voltage of the battery.

- L Terminal – The circuit to the warning lamp is cut off.

- B Terminal – is the main output terminal for the alternator. It has a direct connection to the battery.

- F Terminal – is a regulator’s full-field bypass.

When and where is an Alternator Used?

- Modern automobiles’ electrical systems are powered by alternators. In the past, dynamos or DC generators were used. However, because alternators are more durable and lightweight than DC dynamos, they were eventually substituted.

- An alternator and a diode rectifier are used to change the current from alternating current to direct current, which is what the electrical system of motor vehicles needs.

- An alternator is still employed in spite of the requirement to change the current from AC to DC since it lacks the intricate commutation seen in a DC generator.

- An automotive alternator is the name for the specific kind of generator utilised in the car.

- Alternators are also used in diesel-electric locomotives. The locomotive’s only propulsion system is a diesel engine-driven alternator.

- All of the DC traction motors are fed from the alternating current generated by this generator using integrated silicon diode rectifiers. The locomotive’s wheels are propelled by these DC traction motors.

- Similar to a diesel-electric locomotive, we also employ this device in the maritime industry. We specifically build the synchronous generator used in the marine and navy with the necessary salt-water environment adjustments.

- A marine alternator typically produces between 12 and 24 volts. Multiple units are utilised to produce immense power in large boats and ships.

- In this marine system, the energy generated by the alternator is rectified first and then used to charge the marine’s auxiliary supply battery and engine starter battery.

- Making large amounts of ac power for commercial use is one of the main uses of alternators. Alternators only transform mechanical energy into electrical energy for supply to the power system in

- Thermal,

- Hydroelectric, and

- Nuclear power plants.

- A common statement is that the battery powers every electrical device in the automobile, including the headlights, radio, and windshield wipers. The majority of the electricity in the car is really generated by the alternator. The battery’s main functions are to start the engine and supply power when it isn’t running.

- An essential part of a car’s charging system is the alternator. In the form of an alternating current, the work is completed. The design is simpler and less expensive because the electrical components are made up of a spinning magnetic field and a stationary armature.

- Three main components make up a vehicle charging system:

- Battery,

- Voltage regulator, and

- Alternator.

- Even though alternators now have voltage regulators, the charging system is still incomplete without any one of these three. The battery and alternator operate together to create electricity for the vehicle’s electrical systems, including the interior and external lights.

How does an alternator function?

The following are the functions of alternators:

An alternator’s main function is to recharge a car battery so that other electrical parts of the vehicle can be powered.

The battery is charged, which supplies the starter motor with the electricity it requires to start the vehicle. Alternators also produce energy when the automobile is moving in order to supply the battery and electrical system.

Generators and alternators both perform the same functions.

- Direct current is produced while the pulley turns (DC).

- The electrical current is produced when an alternating current (AC) travels through a magnetic field while the machine is rotating.

The vehicles utilize an alternator, which improves in battery recharging. In order to accomplish that, the alternator must transform mechanical energy into electrical energy.

How Does an Alternator Generate Electricity?

The engine of the car acts as the generator of electricity. However, older vehicles may have a separate pulley running from the crankshaft to the alternator. Typically, alternators are driven by the engine’s crankshaft by a serpentine belt. The alternator’s rotor spins at a very high speed inside the stator as a result of the movement of the belt or the mechanical energy it generates.

Upon starting to rotate, the rotor generates power. In order to pass through the stator’s copper wiring and generate a magnetic field, the magnets that surround the rotor are strategically positioned. The stator captures the voltage that the magnetic field’s creation creates. The voltage regulator, which controls how much voltage is delivered to the battery and is transferred to the vehicle.

How does the battery get charged by the alternator?

The power from the alternator must be transformed into a form that the battery can use it. This is because there are various currents or directions in which electricity can flow. In contrast to alternators, which produce alternating current (AC), which occasionally flows backward, car batteries use one-way direct current (DC) electricity. In order to convert AC power meant for the battery to DC, a diode rectifier is used before it reaches the voltage regulator. The battery can use the electricity to recharge itself upon conversion.

Various Alternator Types:

Depending on their designs and applications, alternators can be categorised in a variety of ways.

According to their intended use, the 5 varieties of alternators are as follows:

- Automotive Alternators: are featured in contemporary vehicles.

- Diesel-electric Locomotive Alternators: employed in numerous diesel-electric units.

- Radio Alternators: utilised for low band radio transmission.

- Marine Alternators: utilised for marine applications.

- Brushless Alternators: employed as the primary source of energy in facilities that produce electricity.

Alternators are also divided into categories based on design:

- Smooth Cylindrical Generators: design of an alternator powered by a steam turbine.

- Salient Pole Types: are mostly employed in low-speed turbines like those found in hydroelectric plants.

Advantages of An Alternator:

The benefits of an alternator include

- Cheap

- small weight

- simple to maintain

- Simple to assemble

- Robust

- more simplified

Disadvantages of An Alternator:

The disadvantages of an alternator include:

- Transformers are required for alternators.

- If the current is high, alternators will become too heat.

Application of An Alternator:

An alternator is used for the following things:

- Multiple units powered by diesel power stations,

- Plants that produce electricity,

- Transmission of radio waves,

- Automobiles,

- Nautical applications,