- What is Servo Motor?

- What Does Stepper Motor mean?

- Comparison of stepper motor & servo motor

- Explain Micro-stepping in Stepper motor

- What is Motor Efficiency?

- Describe about motion Control in Servo motor & Stepper motor

- List few similarities between Stepper motor & servo motor

- Why would you use a stepper motor instead of servo motor?

What is Servo Motor?

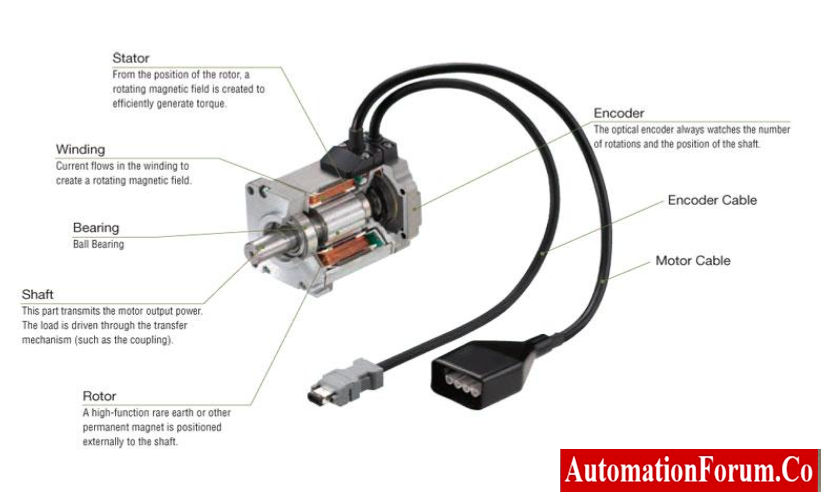

- A specific type of linear or rotary actuator is referred to as a “servo motor” in general.

- In essence, the phrase “servo motor” refers to a mechanism in which the motion of the motor is controlled by constant monitoring.

- A linear actuator or rotary actuator, the servo motor.

- The angular or linear location, velocity, and acceleration can all be controlled precisely.

- It consists of an appropriate motor connected to a position feedback sensor.

- A common variable speed drive in industrial production, process automation, and construction technology globally is the servo motor.

- They are intended for use in motion control applications that demand great performance, rapid reversing, and high positioning accuracy.

- This blog teaches us about the various servo motor types that can be used in various fields.

How does servo motor work?

- One of the characteristics that makes servos so dependable is their simplicity. Little direct current (DC) motors, such those in low-cost toys, are the basic building blocks of servos.

- These motors are powered by batteries and have high RPMs (rotations per minute), but they produce relatively little torque

- The motor’s fast speed is slowed down while also increasing torque due to a gearbox arrangement. (Work = force x distance)

- Although a little electric motor has little torque, it may spin quite quickly (small force, big distance).

- The output is changed to have a considerably slower rotation speed but increased torque thanks to the gear configuration inside the servo casing (big force, little distance).

- To keep it lighter and less expensive, cheap servo motors typically include plastic gears.

- The gears of a servo built to deliver more torque for heavier operations are constructed of metal and are more durable.

Types of Servo Motor

- AC Servo motor

- DC Servo Motor

- Linear & Rotational Servo Motor

Advantages of servo motor

- High performance

- Faster speeds

- Precise positioning (because of feedback)

Disadvantages of servo motor

- Costlier (though less of an issue today)

- Required setup and tuning adjustment

What Does Stepper Motor mean?

- A DC motor that operates in distinct steps is known as a stepper motor.

- It is a synchronous brushless motor with a number of stages that make up one full rotation.

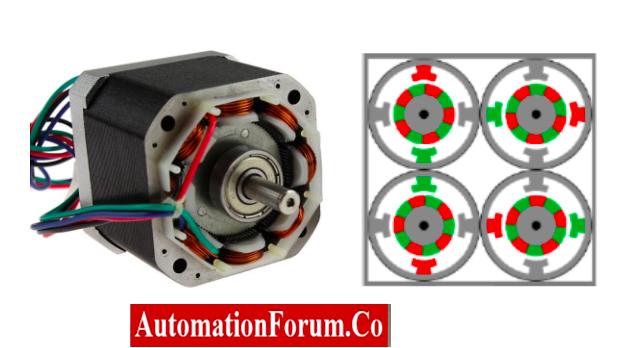

- The rotor and the stator are the two major parts of a stepper motor.

- The motor’s rotating shaft is called the rotor, and its stationary component, the stator, is made up of electromagnets.

- Stepper motors are produced with steps per revolution of 12, 24, 72, 144, 180, and 200 and corresponding step angles of 30, 15, 5, 2.5, 2, and 1.8 when a discrete DC voltage is applied. This rotational angle is known as the step angle.

- Users may regulate it either with or without feedback.

Explains Stepper motor principle

- An electromechanical device known as a stepper motor transforms electrical pulses into precise mechanical movements.

- A special type DC motor that doesn’t revolve constantly is called a stepper motor.

- An entire rotation is instead broken up into a number of equal stages.

- Phases, which are several coils arranged into groups, make up a stepper motor.

- The stepper motor turns one step at a time by delivering energy from the input voltage to each phase in turn.

- As a result, a stepper motor transforms electrical energy or a digital input pulse into mechanical shaft rotation.

- The rotor, which can be either a permanent magnet or soft iron, is encircled by electromagnetic stators.

- Rotor and stator poles may have teething.

- The magnetic effect causes the rotor to move towards the stator or align itself with it when voltage is applied at the terminals.

- A full revolution is produced by sequentially energising the stators and moving the rotor, which results in a specified number of steps with a specific step angle.

How does a stepper motor work?

- We can observe that in the initial position, the rotor starts at the higher electromagnet, which is currently in operation (has voltage applied to it).

- The right electromagnet is turned on while the upper electromagnet is disabled to move the rotor clockwise (CW), which causes it to rotate 90 degrees and line up with the active magnet.

- Until we return to the beginning location, this process is repeated in the same way at the south and west electromagnets.

Types of stepper motor

- Permanent Magnet Stepper

- Variable Reluctance Stepper

- Hybrid Step Motor

Advantages & Disadvantages of stepper motor.

- Versatility

- More Torque

- More affordable than servo motors

- Stepper Motors Are Generally viewed as Safer motor.

- Stepper motors offer excellent repeatability and a longer life.

- Outstanding Low Speed Torque

- Stepper motors are safe against overload.

- The Stepper Motor’s Rotation Angle Corresponds to the Input Pulse.

- Stepper motors deliver their full torque when stopped.

- Low-speed Synchronous Rotation

- A good option for applications requiring high precision at low speeds.

Disadvantages of Stepper motor

- Low Effectiveness

- A stepper motor’s torque rapidly decreases with speed

- Poor Precision

- There Is No Feedback Given to Highlight Potentially Missed Actions

- High Inertia to Torque Ratio

- A really loud stepper motor

- Holding torque must be eliminated

Comparison of stepper motor & servo motor

The different characteristics of DC brushed type Servo motor is compared with Hybrid Stepper motor

| Characteristics | DC Brushed Servo Motor | Hybrid Stepper Motor |

|---|---|---|

| Cost | A stepper motor system with an equivalent power rating is less expensive than a servo motor system. | Stepper motors would have to be used for this feature. In general, steppers are less expensive than servo motors with the same power rating. |

| Versatility | The usage of servo motors in automation and CNC applications is quite flexible. | Stepper motors are incredibly versatile and can be found in everything from clocks to printers. |

| Reliability | It depends on the environment and how effectively the motor is protected, so this is a toss-up. | The stepper is included in this category only because it does not need a potentially defective encoder. |

| Frame Sizes | There are many different frame sizes for servo motors, ranging from small to giant motors that may power enormous equipment. Many motors are available in NEMA standard sizes. | In the larger sizes, stepper motors don’t come in as many different sizes as servo motors. |

| Setup Complexity | To achieve proper motor function with servo motors, the (PID) closed loop variable circuit must be tuned. | The majority of stepper motors are plug-and-play. All that must be connected to the stepper motor driver are the motor wires. |

| Motor Life | Servo motor brushes need to be changed after 2000 operating hours. Encoders may also need to be replaced. | The only consumable component in stepper motors is the bearing. As a result, stepper motors have a modest advantage in life. |

| Low Speed High Torque | Given little friction and the appropriate gear ratio, servo motors will function properly in low speed applications. | At low speeds, stepper motors produce the most torque (RPM). |

| High speed High Torque | At about 90% of their no load RPM, servo motors continue to deliver their rated torque. | At 90% of their maximum RPM, stepper motors can lose up to 80% of their maximum torque. |

| Repeatability | If set up properly, servo motors can have very good repeatability. The repeatability may also be influenced by encoder quality. | Stepper motors offer very good repeatability and require little to no adjustment due to the way they are built and function |

| Overload Safety | Servo motors may break down if they are mechanically overloaded. | Mechanical overload is unlikely to harm stepper motor |

| Power to Weight/Size ratio | With respect to efficiency, servo motors have a great power to weight ratio. | Since stepper motors are less efficient than servo motors, their power to weight/size ratio is often lower. |

| Efficiency | Servo motors are quite effective. 80–90% efficiency yielding under light loads. | Given their output, stepper motors need a lot of electricity, much of which is converted to heat. Typically, stepper motor efficiency is around 70%, however the stepper driver does have a role in this. |

| Flexibility in motor resolution | A servo motor’s encoder defines its resolution, hence there is a wide range of resolutions possible. | Stepper motors typically have a resolution of 1.8 or 0.9 degrees. However, steppers can achieve better resolutions because of micro-stepping. The driver, not the motor, is in charge of this. |

| Torque to Inertia Ratio | The ability of servo motors to accelerate loads is very strong. | While stepper motors may accelerate loads, they can’t match servo motors in this regard. If the motor is not powerful enough, stepper motors may stall and skip steps. |

| Least Heat production | Heat production is extremely minimal since a servo motor’s current draw is inversely proportional to the applied load. | Stepper motors consume too much current no matter the load. Heat is produced when too much power is used. |

| Reserve Power and Torque | At brief times, a servo motor may deliver about 200% of the constant power. | Stepper motors lack a power reserve. Stepper motors may, however, brake very effectively. |

| Noise | Servo motors make a relatively little amount of noise. | Stepper motors emit a small hum as a result of the control mechanism. A good driver will, however, reduce the noise intensity. |

| Resonance and Vibration | Servo motors are free of resonance problems and vibration. | Because of the way stepper motors work, they vibrate somewhat and have some resonance problems. |

| Availability | Stepper motors are more widely accessible than servo motors to the general public. | Compared to good servo motors, stepper motors are much simpler to find. |

| Motor Simplicity | Because of their internal components and external encoders, servo motors are more mechanically complex. | Stepper motors have a relatively straightforward design and don’t have any manufactured consumable parts. |

| Direct Drive Capability | Due to their high RPM, servo motors typically demand higher gearing ratios. A system with a direct drive servo motor is extremely uncommon. | Direct drive mode will function properly with stepper motors. Many individuals just use a motor coupling to quickly and securely connect the motor shaft to the leadscrew or ball screw. |

| Power Range | Servo motors offer a very broad power availability range because they are available in DC and AC. | Stepper motors have a different power availability range than servo motors. |

Explain Micro-stepping in Stepper motor

Micro-stepping application in stepper motor is obtained without adding mechanical hardware such as gear reduction. Micro–stepping involves pulsing the enable pin at a specified duty cycle to generate an intermediate voltage.

What is Motor Efficiency?

When a motor uses the interaction of a magnetic field and current in its winding to produce and generate force or torque, motor efficiency is the measurement of the quantity of mechanical work the motor accomplishes and the electrical power it consumes to complete the work.

Describe about motion Control in Servo motor & Stepper motor

- Stepper motors move gradually with a constant pulse in a closed-loop system due to this difference in pole count.

- Encoders are necessary for servo motors in order to modify pulses for position control.

Servo Motors in Motion Control

Pros and cons

The fundamental advantage of servo motors is that they can deliver large amounts of torque at high speeds, something stepper motors are incapable of.

- They work with an efficiency of between 80 and 90%.

- Servo motors are vibration- and resonance-free and can operate with either an AC or DC drive.

- While servo motors have many benefits, one significant disadvantage is that they are far more expensive than stepper motors.

- The price of the gearbox and encoder together can make the system as a whole quite expensive.

- Moreover, the requirement for an encoder and gearbox increases the mechanical complexity of the system, increasing the need for maintenance and raising expenses.

Stepper Motors in Motion Control

Pros and Cons

- Due to its numerous poles, stepper motors provide precise drive control for motion control applications.

- They are widely available, reasonably priced, and have a high torque at low speeds.

- Nonetheless, stepper motors have their limits.

- They lose almost all of their torque at high speeds, sometimes even up to 80%.

- They generate a lot of vibration and are prone to resonance problems.

- High heat output from stepper motors might be problematic in some applications.

List few similarities between Stepper motor & servo motor

- High positioning precision.

- Mechanical assembly that is small.

- Decreased number of machine parts.

- Extremely smooth speed.

- Operating in silence.

Why would you use a stepper motor instead of servo motor?

- With efficiencies of between 80 and 90%, servo motors are more effective than stepper motors.

- In terms of overall performance, stepper motors are better suited for lower acceleration, high holding torque applications than servo motors, which are suitable for high speed, high torque applications.