In certain conditions, we won’t be able to use an electronic flowmeter so in that case, we can use a mechanical flow meter. So unlike an electronic flow meter, the mechanical flowmeter has moving parts like turbine or rotors and that’s the major difference between an electronic flow meter and a mechanical flow meter. The mechanical flow meter would utilize these moving parts to measure the flow rate. We can use a mechanical type flow meter to measure the fluids or gases.

- What is a velocity flow meter?

- What is a meter prover?

- What is a target flow meter?

- What is the importance of flow measurement in process control?

- What is a positive displacement flow meter and what are its types?

- What is a propeller flow meter and where is it used?

- What is orifice meter and what is the use of orifice meter

- What is a flow meter and What are the types of flow meter

What are the types of mechanical flow meters?

Multi-jet meters

A multi-jet is a form of velocity meter and it has an impeller and this impeller would rotate horizontally on a vertical shaft. The impeller is in a housing that contains multiple inlet ports and these ports would transfer the flow of the fluid to the impeller and thus the impeller would rotate and this impeller rotation is proportional to the velocity of the fluid. The water exits through several openings at different levels. The multi-jet meters are really accurate over a certain range of flow rates and they can always pass sand or other materials. The operation of a multijet meter is almost the same as a paddlewheel meter and the only difference between these two meters is how the ports in a multijet meter direct the flow of the fluid to the impeller.

Piston meters

This type of flow meter would directly measure the actual flow volume. This can be used for liquid and gas measurements too. The operating principle of a piston meter is rotating the piston in a chamber of known volume. The piston would rotate when the chamber fills up and empties the water. So by counting these cycles we can determine the total volume of water.

Applications of piston meter

- It is used for agricultural purpose

- Aircraft fueling

- It is used in the petroleum and raw material industry to measure the high viscosity fluids

- It is used for marine applications

- It is used in the water industry because it can measure water-based chemicals in different concentration

- It is used for renewable fuel applications and it is used in the production, processing, and also for transportation purposes

Woltmann meters

This type of flow meter is used where accuracy and reliability are really important, this type of flowmeter is available in various lengths and connections. These flow meters are not affected by their environment. The pressure loss of this flow meter is really low. The propeller in this flow meter will be rotated by the flow, its inlet and outlet are designed in a way that it can prevent the hydraulic thrust which would act on the propeller. This flow meter can handle high flow rates and also it can handle low flow rates. The rotation of the propeller is used to detect the flow.

Venturi meter

This type of flow meter would measure the flow by constricting the flow this meter can be used to measure high flow and it would have very little pressure drop. In the above image we can see how a venture meter is constructed the first part is the converging cone and the second part is the cylindrical throat and the third one is the diverging cone. So in order to measure the flow in a pipe, the venturi meter will be placed in a pipeline. When the fluid enters the flow meter there will be a pressure drop and when it reaches the throat then its velocity would be increased and the pressure will be decreased and in the diverging section the fluid will flow out of this meter in a good manner. So as we discussed earlier there will be a pressure difference between the inlet section and the throat so by measuring this different pressure at the two parts we can determine the flow rate.

Advantages of venture meter

- Good accuracy and low-pressure loss

- The discharge coefficient is high

- Operation is really easy

- We can install this flow meter according to the required direction in a pipeline

- This flow meter can be used with slurries, gasses, mixed-media, and also can be used with varying viscosity

Disadvantages of venture meter

- They are costly

- Maintenance is really difficult

- It is not suitable for small pipes or pipes that have a small diameter

Dall tube

The dall tube is a small form of a venturi meter and it has a very low-pressure drop. The flow measurement is done by measuring the pressure drop that is caused by the restriction in the conduit. The physical structure of the dall tube is somewhat the same as the venture meter. The dall tube consists of a short straight inlet section and then we can see a decrease in the diameter section and this meter also has the converging and diverging section as in the venture meter.

Advantages of dall tube

- Head loss is really low

- Installation is really easy

- Accurate measurement of the flow

- Erosion and wear is less so less maintenance is needed

Disadvantages of dall tube

- It can be used to measure the fluids that have suspended solids

- Stream disturbance can cause the pressure variation and it would affect the measurement

Orifice plate

In this type of flow meter, an orifice plate will be placed in the pipeline and the differential pressure will be measured during the flow. The orifice plate is basically a flat piece of metal and it would also have a hole bored in it. There are four types of orifice plates, Eccentric orifice plate, concentric orifice plate, quadrant edge orifice plate, and segmental orifice plate.

Advantages of an orifice plate

- Low cost

- It can be used for different pipe size

- It can be used with differential pressure devices

Disadvantages of orifice meter

- Pressure loss will be high

- It can’t be used with slurries

- If the installation is not proper then it would affect the measurement

- It is subjected to erosion, corrosion and because of this they would change characteristics

Pitot tube

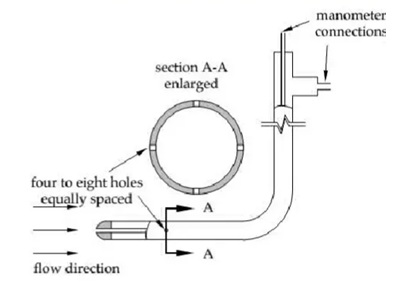

A pitot tube operates by measuring the change in the velocity of the fluid when it passes through an object. Consider that a solid body is placed stationary and centrally in a pipeline so when the fluid that comes closer to this body would reduce its velocity and its velocity will be reduced till it reaches the object. So when it comes close to the object the velocity of the flow is zero and this point is called the stagnation point. So by measuring the pressure difference between the normal flow line and that at the stagnation point we can determine the fluid velocity. Usually, a normal pitot tube would have an impact opening on the tube and this is used to measure the pressure. In the case of an industrial pitot tube, it would have a cylindrical probe and it will be inserted into the air stream

Advantages of the pitot tube

- There won’t be any process loss

- Economical

- Easily installation and removal is possible

Disadvantages of the pitot tube

- Low accuracy

- It can’t be used with dirty fluids

- They are sensitive to upstream disturbances

Multihole pressure probe

The operating principle of this meter is the same as the pitot tube but the difference from a pitot tube is that it has more than one hole in the tube tip. These tubes can detect the flow velocity and the direction too. This device would have three or more holes because of this number of holes the velocity and magnitude can be determined. The holes could be arranged in a line and it would allow the pressure probes to measure velocity.

Paddlewheel

In this type of flow meter, there will be a paddle and it will rotate when the water flows through the pipe. The paddlewheel will be placed perpendicular to the flow path, it is placed in a way that the rotor’s axis is positioned to reduce the contact between the paddles and also the flowing media, and because of this, the paddle will rotate at a speed proportional to the flow in the pipe.

The velocity of the paddle rotation will be proportional to the flow rate in the pipe. The major components of the paddlewheel meter are the paddle wheel, sensor, pipe fitting, and also display controller. So when the paddle wheel rotates past the base of the pickup coil a voltage pulse will be induced. There will be an electronic unit to convert the pulses on the units flow-based and it will be done according to the diameter and also by considering the flow characteristics of the pipe.

Advantages of paddle wheel meter

- Accurate measurement

- The response is fast with good repeatability

- Compatibility is good

- Easy maintenance and installation

- Less pressure drop

- It can measure low flow rates

Applications of paddlewheel flow meter

- Food and beverage industry

- Dyeing industry

- Pharmaceutical industry

- PCB wet process control

- Chemical industry

- Semiconductor industry

Pelton wheel

The Pelton wheel would rotate during the flow and it would convert the mechanical action of the wheel because the liquid flow will be converted into a readable flow rate. Mostly a Pelton wheel is used to generate power.