Feedforward Control System

Feedforward

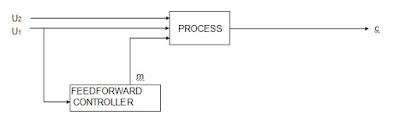

A Feedforward control system measures a disturbance in variable, predicts its effect on the process and applies corrective action.

Given an exact model of the process, the feedforward controller will adjust the manipulated variable (m) so that the controlled variable (c) is unaffected by the disturbance. In fact, the controlled variable has no influence over the control, corrective action is totally in response to their disturbance u1.

This system has three major drawbacks :

1. The model must be exact (including dynamics and nonlinearities).

2. All instruments in the loop must be perfectly calibrated.

3. Disturbances other than the feedforward variable are not controlled.

Thus feedforward by itself is insufficient control. However, combined with conventional feedback, it can be a powerful control tool. If a load change in a process occurs so frequently that the controller cannot keep up, or if the disturbance is so large that the controlled variable cannot be held within tolerable limits, and if the disturbance variable cannot be controlled, consider adding feedforward control to the system.

The feedback controller does the same job and has the same responses and settings as if it were acting alone. It does not have much work to do. The feedforward control cancels the major effect of the measured disturbance. Since feedback acts as the system’s watchdog, the process model need not be exact. In fact, simple gain and lead-lag element will usually suffice.

The effect of load changes other than the measured disturbance will be corrected by the feedback system.

Feedforward and Cascade are often confused because of their similarities : two measured variables, one manipulated variable, one independent set-point. But cascade systems control both measured variables, with the master determining the set-point of the slave. In contrast, feedforward and feedback corrections independently adjust the control valve and there is no control applied to the feedforward variable.