- Definitions in Cable Tray Fill Calculations

- Importance of Cable Tray Fill Calculation

- Step-by-Step cable tray fill Calculation Process

- Example : Cable Tray Area Fill Calculation

- Best Practices for Cable Tray Fill Calculation

- Additional Considerations During Cable Tray Fill Calculation

- What is the fill rate for cable trays?

- How to calculate load capacity of cable tray?

- What is the standard for cable tray?

E&I engineering projects require a cable tray fill calculator to determine the correct tray size needed for efficient cable housing. The calculation provides necessary information to avoid cable overfilling which produces dangerous situations such as overheating, mechanical damage and reduced performance. The primary purpose of this calculator involves the calculation of tray area from specified cable area in combination with fill percentage data.

Electrical installations for industrial, commercial and residential purposes require proper selection and appropriate sizing of cable trays to function correctly. A tray size appropriate for the job enhances safety and cable life expectancy while complying with electrical safety standards. A cable tray fill calculator makes installation easier while preventing mistakes that result in incorrect installations.

Definitions in Cable Tray Fill Calculations

Cable Area:

The cable area represents the measurement of cross-sectional cable dimensions that fit inside the tray expressed in either square millimeters (mm²) or square centimeters (cm²). The calculated value establishes the necessary space which the cables must occupy in their respective tray.

Fill Percentage:

The permitted amount of cable space within the tray falls within a percentage range which ensures satisfactory cable control and ventilation. Electrical Standards establish specific fill percentage restrictions when handling different cable types to achieve thermal safety.

Tray Area:

Tray Area represents the necessary total cross-sectional dimension of the cable tray which meets cable fill percentage requirements. The tray dimensions must prevent cable crowding while avoiding oversized trays that create excess waste and cost inefficiencies.

Conversion Factor:

The Conversion Factor represents a numerical converter that enables the transformation from cm² units to mm² units. By employing conversion factors in measurement calculations the precision of results improves because different units get standardized.

Refer this link to access the Instrument Cable Tray Layout

Importance of Cable Tray Fill Calculation

An appropriately designed cable tray system provides several significant benefits to installations.

- An appropriately designed cable tray system provides several significant benefits to installations.

- The sophisticated cable management system allows proper cable placement to stop equipment entanglement as well as reduce physical strain on the cables. A proper calculation of cable tray fill proves essential when operating in highly dense wiring conditions.

- The compliance of safety regulations includes fill limits which cable tray manufacturers must follow to operate safely. Following these safety rules minimizes short circuit hazards and avoids potential fire occurrences.

- The optimal air circulation system protects cable insulation from damage caused by high temperatures. The excessive heat buildup inside cables leads to degradation and premature termination of their operational lifespan.

- Proper installation economics prevent the use of either unneeded space or excessively large cable trays. Trays that reach their maximum capacity with proper packaging lead to reduced material expenses and most efficient operations.

Refer the below link for the Cable Tray Size Calculation for Project Engineers

Step-by-Step cable tray fill Calculation Process

The procedure to determine necessary cable tray dimensions consists of three sequential steps.

Step 1: Converting Units

A standardized unit of square millimeters (mm²) should first be applied to convert cable area dimensions in order to guarantee calculation consistency. The calculation process uses the specified conversion factor that works as follows:

Step 2: Applying Formula

The determination of necessary tray area follows this specific formula.

Where:

- Cable Area is the total area occupied by cables.

- Fill Percentage ensures compliance with regulations and allows space for proper ventilation.

- Tray Area is the minimum required space to accommodate the cables without exceeding the allowable fill percentage.

Step 3: Converting Units

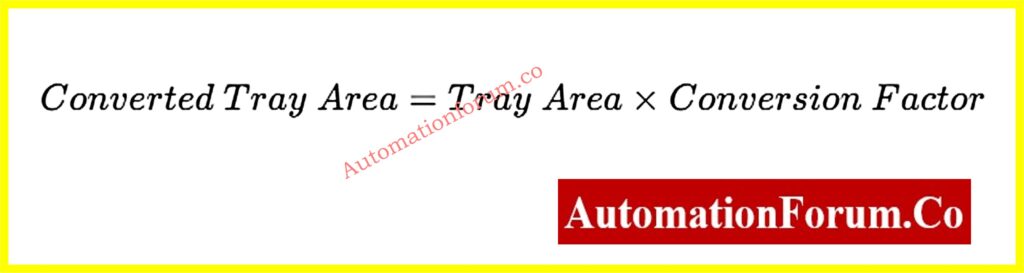

The user can transform the final tray area into alternative units whenever needed. The conversion is done using:

The conversion process enables flexible operations with multiple unit systems.

Refer this link to read about Cable Tray and its Industrial Applications

Example : Cable Tray Area Fill Calculation

When designing cable trays, it is important to ensure that the total cross-sectional area of cables does not exceed the allowable fill percentage of the tray. This ensures adequate ventilation, prevents overheating, and allows for future expansion.

To better understand the process, let’s go through a step-by-step example:

Given Data:

- Cable Area: 50 cm²

- Fill Percentage: 40% (or 0.40 in decimal form)

Step 1: Convert the Cable Area into a Suitable Unit

Since cable area is given in square centimeters (cm²), it needs to be converted into square millimeters (mm²) for consistency in calculations.

We use the conversion factor and Thus, converting the given cable area:

Step 2: Apply the Fill Percentage Formula

The formula to determine the required tray area is:

Thus, the minimum required tray area to accommodate the cables while maintaining a 40% fill ratio is 12,500 mm².

Step 3: Convert Tray Area if Needed (mm² to cm²)

Since we have calculated the required tray area in square millimeters (mm²), we may need to convert it back to square centimeters (cm²) for better readability.

We use the conversion factor and Thus, converting 12,500 mm² into cm²::

Final Result Interpretation

This calculation means that if we have a total cable cross-sectional area of 50 cm² and the allowed fill percentage is 40%, then the required cable tray area must be at least 12,500mm²(125 cm²) to ensure proper cable accommodation.

The cable tray fill calculator functions as an essential instrument which helps electricians together with engineers and contractors maintain proper cable positioning and safety requirements. Using the defined process will help users find correct tray dimensions while maintaining optimal cable functionality and meeting all relevant electrical requirements.

A cable management system achieves safety together with efficiency through careful planning along with adherence to industry specifications and established guidelines. A cable tray fill calculator helps avoid installation mistakes and extends electrical infrastructure lifespan when used appropriately regardless of the industrial, commercial or residential installation requirements.

Refer this link to download and refer the Instrumentation Cable Tray Installation Checklist and Inspection Procedure

Best Practices for Cable Tray Fill Calculation

- Industry guidelines establish various fill percentage designs according to cable types and tray installation types. For instance:

- Power cables: 40% fill

- Control cables: 50% fill

- Communication cables: 60% fill

- Provision for expansion should be built into trays by reserving empty space for potential new cable installations. The extra space maintained in cable tray systems serves to prevent costly reinstallation projects during future cable expansion needs.

- Route cables through straight paths away from areas with crowded pathways because bending angles produce stress on cords. Cables that receive proper routing techniques preserve their design stability together with operational efficiency.

- The installation must follow established industry standards either from NEC (National Electrical Code) or IEC (International Electrotechnical Commission) regulatory codes. The adherence to safety standards through compliance provides electrical installations with their protection and performance reliability.

- Record Keeping of cable tray capacities with current levels determines future planning and maintenance needs to prevent new cables from surpassing tray nominal capacity.

Additional Considerations During Cable Tray Fill Calculation

- Cable trays exist in three major material options which include steel aluminum and fiberglass. The selected material must match environmental requirements because outdoor installations need corrosion-resistant materials.

- Open or ventilated cable trays allow better airflow through their design compared to solid-bottom trays thus minimizing the potential for overheating.

- Each high-voltage and low-voltage cable needs separate space in order to prevent electromagnetic interference that safeguards communication cable signal quality.

- The tray should maintain sufficient strength to handle the complete cable weight without experiencing any structural damage.

Click here to access 100+ Online Instrumentation Calculators Collections

FAQ on Cable Tray Fill Percentage Calculator

What is the fill rate for cable trays?

Cable fill within cable trays should not surpass 50% of the available tray area which is calculated by multiplying width and depth. At a 50% cable fill rate all free space in the cable tray will be occupied since cables are closely spaced together. Cable tray standard recommends 40% fill ratio.

How to calculate load capacity of cable tray?

The manufacturer’s specifications provide you with weight information for each cable type measured per linear foot (or meter). Total cable weight can be obtained through a multiplication of each cable type weight and count before combining all individual cable weights.

What is the standard for cable tray?

IEC-61537 provides an international standard which determines specifications and testing requirements for all metal cable trays together with wire mesh cable tray and nonmetallic cable trays that serve as electrical components for supportive systems in electrical and/or communications setups.