- What is Ratio Control?

- What are the major functions of the Ratio Control?

- How does the ratio control work?

- How to do the Ratio Control?

- What is Series and Parallel Ratio Control?

- When should we use Ratio Control?

- What is the difference between Feed Forward and Ratio Control?

- Example of Ratio Control

- How can we do the Ratio Control of gaseous material?

- What are the advantages of Ratio Control?

- What are the disadvantages of Ratio Control?

- What are the applications of Ratio Control?

What is Ratio Control?

Ratio control can be defined as a type of feedforward control and it is widely used in the process industries. The purpose of the Ratio control is to maintain the ratio of the two-process variable at a specified value. Basically, this is a type of feed-forward control where two disturbances are measured and held in a constant ratio to each other. Mostly the process variable which is to be controlled would be flow rate, manipulated variable, and also a disturbance variable. So by using this type of control we can make sure that the two or more flows (mixed flow) are kept at the same ratio even there are flow variations.

R = u/d

R= Ratio

u = Manipulated Variable

d= Disturbance Variable

In this type of control, an uncontrolled flow would determine the second flow, so that we can maintain the desired ratio between them. The ratio factor would be set by a ratio relay or multiplying unit and this would be located between the flow transmitter and the flow controller setpoint, as we can see in the below image.

Flow B is controlled to the preset ratio of flow A

What are the major functions of the Ratio Control?

- Maintaining the required ratio of reactants to a reactor

- It would keep a specified reflux ratio for the distillation column

- It would maintain the fuel-air ratio of the furnace at the optimum value

- It would set the relative amount, of components in the blending operations

How does the ratio control work?

Ratio control would keep the flow of two or more streams at a constant ratio. In certain cases, the control of one stream could be difficult and in that case, the flow would be measured and after that, the flow rate of the other stream will be controlled. The flow rate of the stream which is uncontrollable is called the wild stream. In case you need to control the flow rate of two-stream, then both the flow rates would be measured and their ratio would be taken. Then this ratio would be compared with the desired ratio and the difference between these ratios would be used to create the actuation signal for the ratio controller. In the ratio control, the signal from each transmitter or sensor must change linearly with the flow. Mostly it would connect the two flows in order to maintain a constant ratio.

How to do the Ratio Control?

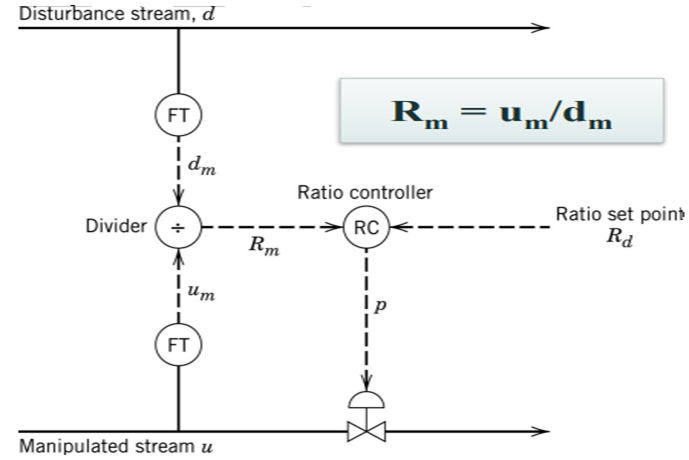

Method 1

um = Manipulated Stream

dm = Disturbance Stream

The flow rate of d and u will be measured, after that Rm will be calculated using the below-shown formula

Rm= um/dm.

Then the output will be transmitted to the Ratio Controller. The Ratio Controller would compare the calculated ratio to the desired ratio. Then the manipulated stream would be adjusted according to that. PI controller would have the desired ratio as its setpoint. This method would be affected badly if the flow is nonlinear.

Method 2

In this method, the disturbance stream (d) would be measured and transmitted to the Ratio station (RS). Then the RS would multiply this signal with an adjustable gain (Kr). The output of the RS would be used as the setpoint (Usp) for the flow controller which would adjust the flow rate of the manipulated stream (U).

What is Series and Parallel Ratio Control?

Series Ratio Control

In the Series Ratio control, the Master and the Leader controllers together form the first loop in a two-loop controller. The Follower control loop which is the second loop in a two-loop controller will be controlled by a remote setpoint value from the Leader flow sensor.

Parallel Ratio Control

In the Parallel Ratio Control, the Master controller would control both the loops simultaneously. The Master controller sets the flow value of both the controllers instead of setting the flow value.

So the advantage of this type of control is that the system will be independent and any electrical noise in one loop won’t affect the other one. The Parallel method is the most reliable method of ratio control when there is a change in the processing load.

When should we use Ratio Control?

Mostly the ratio control is used to maintain the flow rate of one stream in a process at a specified rate relative to that of another. It is used in a process where two variables and two parameters must be maintained in a particular ratio, even if the value of the output changes

We can use Ratio control for these cases

- Blending two or more flows to produce a mixture with specified composition

- Blending two or more flows to produce a mixture with specified physical properties

- In order to maintain the proper fuel and air mixture for the combustion

What is the difference between Feed Forward and Ratio Control?

In a Feed-Forward control, the information that concerns one or more conditions that could affect the control variable is converted into corrective action. In the case of the ratio control, two flows would be measured and they would be kept at a constant ratio with each other.

Example of Ratio Control

In this image the ratio of the two reactants needs to be controlled, one of the flow rates is measured but allowed to float, which is not regulated. The outer flow rate would be measured and adjusted to achieve the desired ratio control. The flow rate of reactant A is measured and added with appropriate scaling, to the measurement of the flow rate of the B. The controller would react to the resulting input signal by varying the control valve in the reactant B input line.

How can we do the Ratio Control of gaseous material?

Gaseous material would vary according to the operating conditions. So we need to do the pressure and temperature correction in this case. So during this case, the mass flow rate of each stream would be calculated and then the mass flow rate would be controlled.

What are the advantages of Ratio Control?

- It would generate a defined ratio for the given two streams

- The model is really simple

What are the disadvantages of Ratio Control?

- So according to the variation of the flowrate the linearity of the flow sensor/transmitter has to be changed

- The process variables which is to be controlled should have a ratio relationship

- One of the flow rates is not measured directly

What are the applications of Ratio Control?

- It can be used to control the flow of two streams

- Fuel/air ratio control in boiler

- Flow rate control

- Chemical reactors

- Injecting modifiers and pigments etc. into resins before molding or extrusion

- Paint mixing plants

- Mixing of mains water and sewage

- Fuel dosing plants

- Blending operations