What is Governor?

A governor is a device that measures and controls a machine’s speed, such as an engine. The centrifugal governor, also known as the Watt or fly-ball governor, is a classic example of proportional control that employs weights mounted on spring-loaded arms to calculate how quickly a shaft is spinning and then uses proportional control to limit the shaft speed.

Working of a Governor:

When the load on an engine increases or decreases, the governor’s duty is to regulate the mean speed of the engine. For example, when the load on an engine increases or decreases, the engine’s speed will obviously reduce or increase to the extent of the load fluctuation. Within modest bounds of mean speed, the governor must manage this variance in speed. As a result, when the load increases and the speed lowers, the fuel supply to the engine must be increased to compensate for the loss of speed and return the speed to the mean speed. When the load reduces and the speed increases, the fuel supply must be reduced.

When there is a variation in load, the governor’s objective is to keep the engine’s speed within a defined range. The governor’s mechanism should work in such a way that the fuel supply is automatically regulated according to the load required in order to maintain a constant speed.

Types of Governor:

Governor is classified into two major types. They are:

- Inertia Governor and

- Centrifugal Governor

Inertia Governor:

The centrifugal governor and the inertia governor are not the same thing. Angular and centrifugal forces combine to control the position of the balls and the governor’s operation. It is preferred when a rapid response is required due to its uniqueness.

In addition to centrifugal forces on the balls, inertia governors alter the position of the balls by forces set by an angular acceleration or deceleration of the provided spindle.

Centrifugal Governor:

The engine-driven centrifugal governor is a fly weight mechanism is coupled to the throttle and operates against a spring in a similar manner to the inertia governor, resulting in practically identical operation. The design and manufacture of a centrifugal governor is more difficult than that of an inertia governor. The centrifugal design, on the other part, is more sensitive to speed changes and hence better suited to engines with large load fluctuations.

The Centrifugal Governor is classified into different types they are:

- Porter governor

- Proell governor

- Watt governor

- Hartnell governor

Porter Governor:

The porter governor is a Watts governor modified with a central load linked to the sleeve. The load is transferred up and down the central spindle. This added downward force raises the required speed of revolution for the balls to ascend to any pre-determined level.

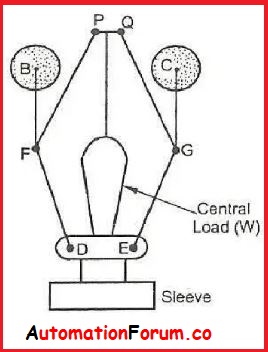

Proell Governor:

A gravity-controlled centrifugal governor is a form of Proell engine speed control governor. It’s built similarly to a porter mechanical speed governor. Like the porter governor, it has a central load. The balls, on the other hand, are attached to the extension links in the Proell governor, as indicated in above diagram. The speed of the Proell governor is lower than that of the Porter governor for a known mass of Governor ball and centre load.

Watt Governor:

The Watt Governor is the most basic type of centrifugal governor. To regulate the speed of his steam engines, watt governor are used, often known as a “flyball governor.” It’s essentially a conical pendulum with a link to a little sleeve. It is made up of two balls that are linked or fastened to the spindle via links or arms. Three options exist for connecting the governor’s arms to the spindle:

- It’s possible that the pivot is located on the spindle’s axis.

- When the pivot is offset from the spindle axis, the arms meet at O.

- The arms cross the axis at O, despite the pivot being displaced.

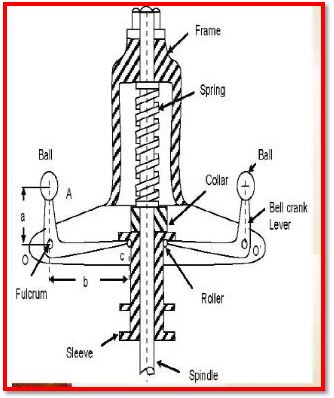

Hartnell Governor:

The Hartnell Governor is similar to the watt governor in that it supplies a specific amount of fuel to the engine to reduce variations. The Hartnell governor, on the other hand, is made up of a few distinct pieces for accurate operating and high-speed performance. This sort of governor has a spring that helps to exert an additional force on the sleeve. and there is a bell crank lever to support the ball’s rotation and is attached to the governor’s frame, and when these balls rotated, the lever would lift the sleeve according to the speed of the balls rotation. An extra nut is provided above the frame on this governor, which is used to regulate the spring force.

How Governor is used to control speed in turbine?

The governor of a steam turbine is a part of the turbine control system that controls rotational speed in response to changing load circumstances. The governor output signal controls the position of a steam inlet valve or nozzles, regulating the flow of steam to the turbine.

Governors are installed on every steam turbine to control speed under the following conditions:

- When the shaft’s mechanical speed exceeds 110 percent.

- The turbine’s balancing gets pushed off.

- The lubricating system has failed.

- The vacuum in the condenser is low, or the coolant supply to the condenser is insufficient.

Applications of Governor:

- Governors are installed in the ship’s auxiliary diesel engines or generators, as well as alternators.

- In a steam engine, a governor is used to adjust the speed according to the load by controlling the fuel supply.

- Governors are used in thermal, hydro power plants to control speed of the turbine.