What is a real time system?

A real-time system is a system that would produce a proper response within a definite time limit. If the controller response is exceeded beyond these time limits then it would affect the process output. Basically, real-time is a measured value by using a real clock, a real-time system would take inputs from the plant and it would send a proper control signal to the plant according to the determined time for the plant operation. A system can be called a real-time system if it describes the behavior of the system by using the expression of time. The real-time system basically processes any signal and this signal must respond to the generated input within a specified time. This type of system can’t be considered a quick operating system.

- What is an event-based controller?

- What is controller tuning

- What is the importance of a controller in process control?

- What is cascade control?

- What is a feedback control system and what are its types?

- What is an automatic control system?

What are the types of real time system?

Clock based system

In this type of control system a time constant is measured, the time constant is a measurement of the required time of the plant to respond to a variation in the input or the load. The time constant could be measured for certain hours in the case of a chemical process. In feedback control, the required sampling rate is dependent on the time constant of the process that is to be controlled. The sampling rate will be very faster if the processing time constant is low. The clock will be added to the computer system and this will be a real-time clock and the signal from the clock will be transmitted to the computer system at the required time. This type of system is used to do cyclic or periodic tasks in a process plant.

Event based task

In this type of system, the actions are done according to an event, so the controller would act only as a response to an event. So this type of control system doesn’t work on time intervals and an important requirement of this system is that it must quickly respond in case of an event. This system is used to close a valve if the water level reaches the maximum limit in the tank.

Soft real time system

In this system, if it is not capable to produce the required result at a proper time then its operation will be degraded. So in the soft real-time system if some of it couldn’t achieve the deadline then it won’t affect the process. So if the overall performance is good then there won’t be any problem but it is not the case for the hard real-time system. An example of a soft real-time system will be the manufacturing system with the robot assembly lines. So in this manufacturing line if the deadline is missed then there will be an improper assembly of the parts. So if the damaged part is infrequent enough to, detected by the quality control and if it is not that costly then the production will continue. If the load is really high in this type of system then its response will be slow.

Hard real time system

This system must do the required action on each and every occasion, so in this system, the operation will be wrong if they don’t produce the results at the required time. If the response time of the hard real-time system is not proper then it would affect the whole process. The peak load performance of the hard real-time system must be predictable and it should not violate the deadline requirements. This system must remain synchronous with the environment state all the time. An example of the hard real-time control system will be the temperature control loop of the hot air blower system.

What are the types of programs used for the process control?

Sequential control

The actions are done in a time sequence, the response of this program is depended on the effect of individual actions.

Multitasking

Certain actions must be performed in parallel, this program will be created from parts and they are partly sequential and will be executed at the same time. This would communicate by through shared variables and synchronization signals.

What are the concepts of computer controls in a system?

Batch

It would describe a process in which a sequence of operations is carried out to create a certain quantity of products and this sequence will be repeated again to create further batches. The product specification or the composition could be changed for different runs. The time that is required for the preparation of equipment for the next production batch is called the setup time.

Continuous

In this type, the production will be maintained for a long period of time and this will be maintained without any interruption. This production could last for several months an example of this will be the catalytic cracking of the crude oil.

Laboratory

This type of system is the frequent operator initiated type, in which a computer is used to control some complex experimental tests or some computer equipment would be used for routine testing.

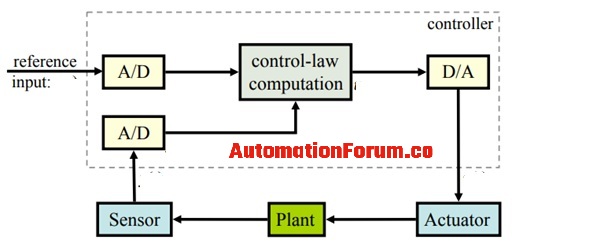

What is a digital process control?

In this type of process control, electronic components are used to do the process control. This would control some devices in a plant by using an actuator, effective control of the plant is dependent on the sensor measurement accuracy, the timing of the clocked data, and resolution of the sampled data. The sampling period must be chosen properly and accurately to ensure its stability. This type of process control system will be composed of many sensors and actuators and all of them would need different sampling periods.

Assumptions of digital controller

The digital controller makes three assumptions, first one is the sensor data would give the proper value of the variable that is being monitored and controlled. The second one is that the state of the plant can be determined by the sensors and the plant state can be computed from the measured values. The third assumption of the digital controller is that all the parameters representing the plant dynamics must be known. If these are not the proper assumption of the digital controller then a model of the correct system behavior must be added to the controller. The estimated plant state should be used instead of the measured state of the drive control output.

What are the requirements of a real time system.

The real-time system is composed of communication networks and these networks take care of the communication of the whole system.

A real-time system should perform its operation on time and in order to this its communication should be better too, like sending and receiving of the message. A real-time system should be able to handle the complexity of the time constraints, it must be flexible and these systems must be dependable. The real-time system must be able to handle the errors that could happen in a process and they should be able to correct these errors and continue with its operation.

What are the applications of real time system?

- Process control system

- Industrial automation system

- SCADA

- Robotic equipment

- Real-time systems are used for many medical applications

- An automotive engine control system, road traffic signal control

- It is used in many defense applications such as missile guidance system and satellite-based surveillance system