What is an HMI display?

The human-machine interface is the interface between the operator and the machine. We can consider the HMI as the operator interface this is an interface method in which several types of equipment are viewed and controlled by an operator in a host control system. The interface between the operator and the machine could be achieved through touch, sound, sight, etc. The major purpose of an HMI is to reduce the communication barrier between the operator and the machine. In order to display the data regarding the industrial process HMI display would be useful. So according to this data, we could make changes in the process, and thus process control can be achieved.

What are the major functions of an HMI display?

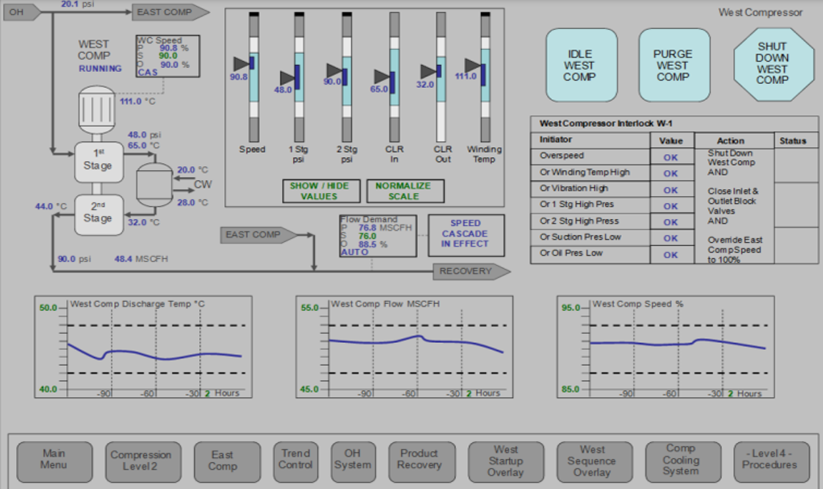

Machine control and process control involve a lot of data variables, and some of these data are related to the controller I/O and the controller status. There are also data for system management, calibration, and a lot more. So the HMI would organize all these data and displays it to the operator with less complication. So the operator can analyze these data and can take required actions according to this data. The HMI would display the real-time process data and due to this industrial control can be easily achieved.

What are the major requirements for an HMI display?

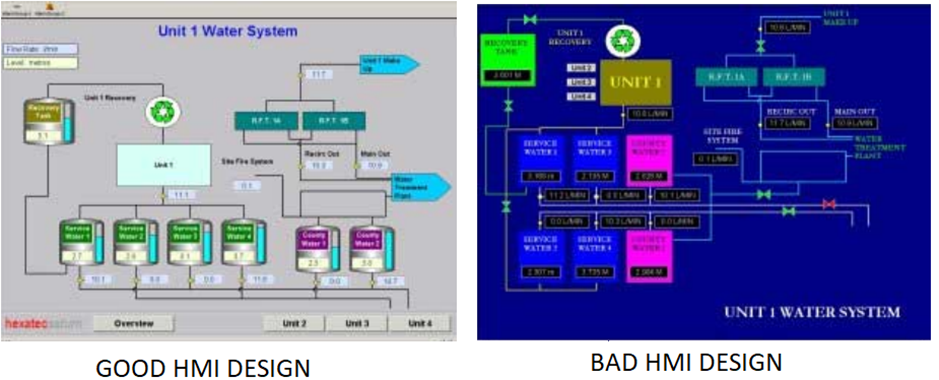

In order to make an HMI display good, we should consider several factors like proper use of colour, layout, content etc. If the operator couldn’t figure out the details which have been displayed then a lot of problems could happen due to this. So if an HMI displays bright colours, with improper layout could lead to many communication problems. So an HMI should have a good layout, proper colours, good navigation, good alarm indication, and proper usage of texts and colours.

How to design a good HMI display?

- Use light colours for background like grey

- In order to subdivide a display shadowing can be utilized

- Alarm colours shouldn’t be used as background colours

- Use standard forms for texts and the operator should be able to read it from a certain amount of distance

- Detailed texts should be included in the pop-up windows

- Choose the colour combination with proper care and use proper colour contrast

- Abnormal conditions such as alarms should be displayed by catchy colours such as red

- Navigations buttons must be visible

- It should have the proper combination of shapes and colours

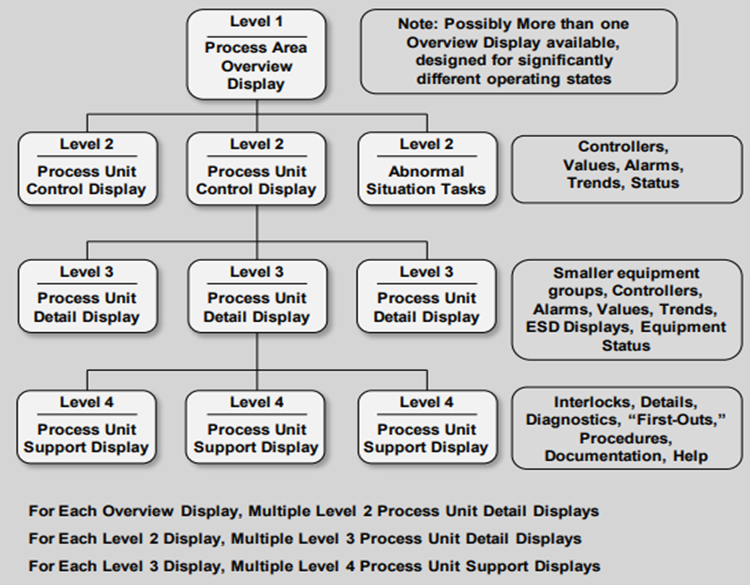

- Prepare displays with ASM based display level hierarchy for easy and faster navigation and control.

To know more about ASM standards click here

What are the different levels of HMI screen and their advantages?

Level 1 display (overview)

This display would provide the area-wide overview and it would provide certain details such as summary status information. This display would provide an overview of the entire system, in this level control interactions are not made we can go to level two with the help of menu buttons.

- It would display the key performance indicators such as efficiency, quality etc

- It would display the alarms

- We could determine the major equipment factors

- It would display the abnormal situations if any

- Displays the important parameters

- It would show the current operation status

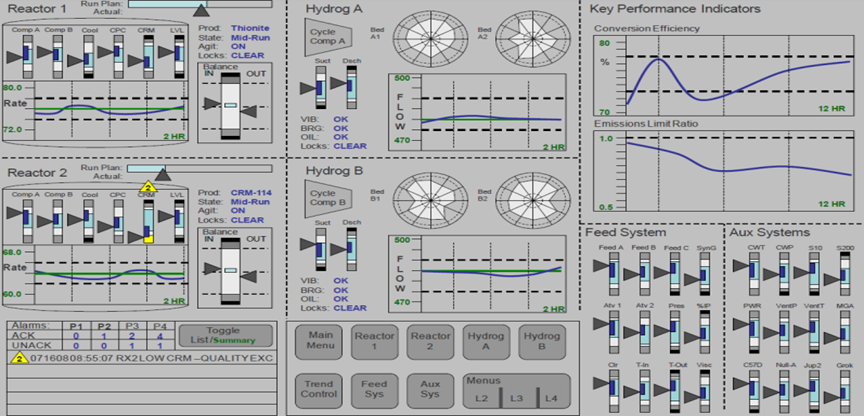

Level 2 display (summary)

This display is used to do the operator tasks and this display is composed of many controls which are required to complete a task. This level displays each separate major unit operation in order to get more details there are final control buttons at bottom of the screen that can be used to go to level 3.

- It has controllers and also it displays the values

- It can be used for troubleshooting

- It also displays the alarms, trends, and status

- Monitoring and control functions can be done

- It has indicators that are required to carry out a task

- It would navigate to the related and also to the overview display

- Abnormal situations would be indicated along with their severity

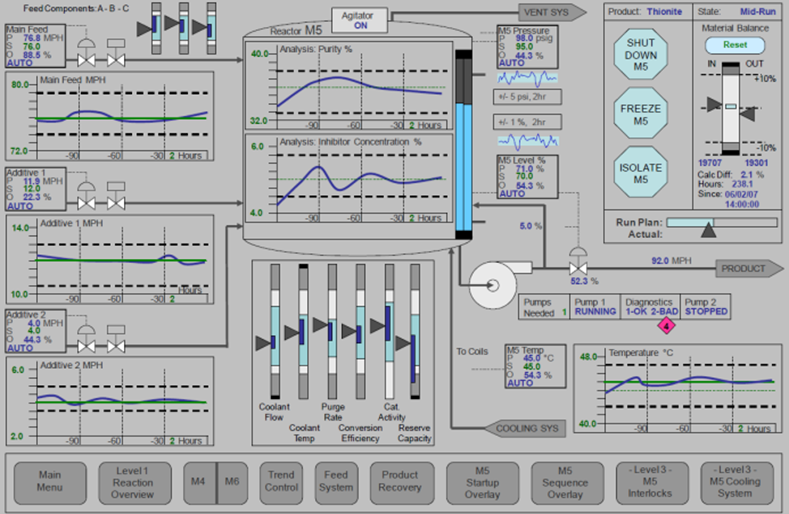

Level 3 display (equipment)

At this level, it has more details regarding the controls and equipment. This level shows the system that supports the major unit operations. By using the menu buttons and we can go to level four.

- It would display alarms of all priorities

- It can be used for detailed troubleshooting

- We could get a detailed view of the equipment

- Control loops and indicators

Level 4 display (Details)

We would require some support documents for complex systems and this is why the level four display is required. In this display, you can see

- Alarm documentation and guidance

- Trends

- Alarm summary

- Operating procedure

- Help options

- We could see the detailed information about the equipment

- Advanced process control features

In short, we can say that the Level1 display is to check the parameters, and the Level2 display is to do the control in case it is required. The Level3 display is to do the advanced control in case the process requires this type of control, and the Level4 display is to display supporting displays.