Electrical Protective Device

A device used to protect equipment,machinery,components and devices,in electrical and electronic circuit,against short circuit,over current and earth fault,is called as protective devices.

Necessity of Protective Devices

Protective devices are necessary to protect electrical appliance or equipment against

a)Short Circuit

b)Abnormal variations in the supply voltage

c)Overloading of equipment

d)To protect operator against accidental contact with the faulty equipment,falling which the operator may get a severe shock.

Types of Protective Device

Different types of the protective device that are commonly used in electrical and electronic circuit

1.Fuse Wire or Fuse

2.MCB – Miniature circuit breaker

3.ELCB – Earth Leakage Circuit Breaker

4.ELCB & MCB

5.Earthing or Grounding

1.Fuse

Fuse generally means a fuse wire,placed in a fuse holder.It is a safety device,which protects electrical and electronic circuit against over loads,short circuit and earth faults.

The fuse link or fuse wire is made of low resistivity material and low melting point.

Fuse is a short length of wire designated to melt and separate in case of excessive current.

The fuse is connected in the phase of the supply.

It is always connected in series with the circuit / components that need to be protected.

When the current drawn by the circuit exceeds the rated current of the fuse wire,the fuse wire melts and breaks.This disconnects the supply from the circuit and thus protects the circuit and the components in the circuit.

Rating of Fuse Wire –

The maximum current that a fuse can carry,without being burnt,is called the rating of the fuse wire.It is expressed in Amperes.

Current rating of the fuse,selected for the circuit,should be equal to the maximum current rating of the machinery,appliance or components connected in the circuit.

Fuse Carrier and Fuse Channel –

Fuse carrier and channel are made of porcelain or Bakelite material.They are used for all domestic,commercial and industrial application upto 100 A capacity.

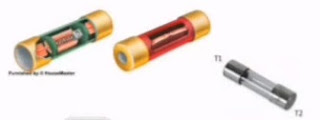

Cartridge Fuse

This fuse unit is in the form of a cartridge.

Its normally manufactured in the range of 2 A to 100 A.

Whenever the fuse blows off,fuse with carrier is replaced by a new one.

As it is sealed,it cannot be rewired.

Cartridge fuses are used to protect motors and branch circuit where higher amps or volt ratings are required. They are available in wide variety of sizes,amp and volt ratings up to 600 Vac and 600 amps.

Cartridge fuses are used extensively in commercial,industrial and agricultural applications as well as residential fuse panels,air conditioning,pumps,appliances and other equipment.

Cartridge Fuses are available in two types-

General purpose fuses have no time delay and protect fuse panel,appliances and branch circuits

Heavy duty fuses have a time delay feature.

HRC Fuse

HRC Fuse – High Rupture Capacity fuse unit.It is normally designed for high current.When fuse is blown off,the entire unit is to be replaced by a new one.It cannot be rewired as it is a sealed one.

Characteristics of a good fuse wire

A good fuse wire should possess the following characteristics

a)Low resistivity

b)Low melting point

C)Low conductivity of the metal vapors formed,when the fuse is blown off.

Advantages of HRC Fuse

1.They require maintenance

2.They are reliable

3.They operate at high speed.

4.They have consistent performance

5.They clear both low and high fault current with equal efficiency.

2.MINIATURE CIRCUIT BREAKER

It is safety device which work magneto thermic release principle.It is connected in the phase,between the supply and load.It is manufactured in standard rating of 6A to 40 A.We can see it on the meter board of each and every house.

When the current drawn by load exceeds the rated value,it acts and trips the circuit,the protecting the apparatus,operator and appliance.

Advantages of MCB

1.They act and open the circuit in less than 5 milli seconds.

2.Automatic switch off under overload and short circuit condition

3.No fuse to replace or rewire.It needs no repairs.

4.Supply is restored by resetting it again.

3.EARTH LEAKAGE CIRCUIT BREAKER

This is a domestic safety device,which trips the circuit when there is a small leakage to earth or body of the appliance.Thus it protects the operator from shocks and accidents.This is connected in the circuit of the appliance to be protected.

There are two types of ELCB

1. Voltage Earth Leakage Circuit Breaker

2. Current Earth Leakage Circuit Breaker

4.MCB & ELCB

It is the combination of both MCB and ELCB palced in one unit.It acts on both the occasion of earth leakage and overload and protect the circuit,appliance and the operator.

5.EARTHING OR GROUNDING

Connecting the metal body of an electrical appliance,machinery or an electrical installation to earth,through a low resistance wire,is called Earthing or Grounding.

Necessity of Earthing

Earthing is necessary for all domestic,commercial and industrial installation to safeguard the operator,tall buildings and machinery against lightning.

Metal body of all the electrical appliances,equipment and machinery,the earth points of all three-pin sockets and the body of the energy meter are connected to earth through a thick G.I. wire.

Whenever a live wire comes in contact with the body of the appliance,it is directly connected to earth the grounding wire and hence the body voltage comes to zero.Therefor the operator does not get any shock,when he comes in contact with body of the appliance.

The high voltage included during lightning is discharged to earth through grounding wire and thereby building and machinery are protected.