Pneumatic Control System

What is pneumatic ?

Pneumatic is the technology that makes use of gas or pressurized air.

Components of Pneumatic control system

1.Directional control Valves

These are functional valves used in logic implementation.

Divided according to the number of ports / passages available and number of valve positions

2.Two Way Valves

Has two ports

Are Manually operated , Pilot operated or Solenoid operated

Either Normally Open or Closed

In one position IN and OUT ports are connected

In another position, IN and OUT ports are isolated

3.Three way valves

The mostly used logical component.

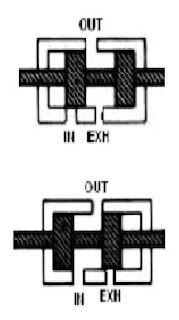

In one position IN is blocked and OUT connected to Exhaust

In another position IN gets connected to OUT and the EX port blocked

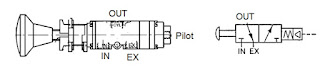

4.Manually Operated 3 Way

Manual ‘push’ changes the normal position of the valve

In a spring return valve, position returns to normal condition on manual release.

3 way Valve Paths

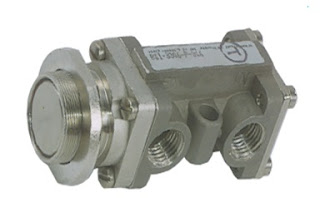

5.Pilot Operated 3 way

The pilot is opposed by a spring tension, which returns the valve to its normal position on pilot removal

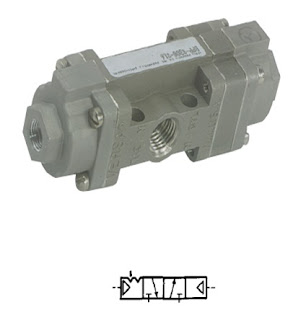

6.Pilot Operated Pilot Return

No spring to return the Valve

2nd Pilot used to return the valve

Port configuration is stay put until next pilot

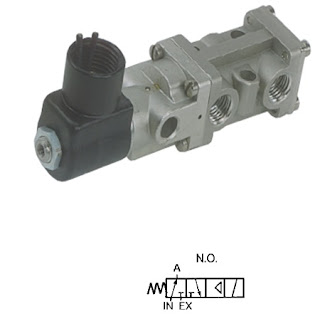

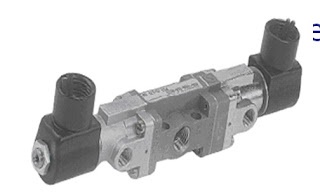

7.Solenoid Operated 3 Way

Piloting done by solenoid

The solenoid coil is magnetized by applying electric power

8.Solenoid operated solenoid return

Used Where electric pulse is preferred over continuous supply

9.Manual Reset Valve

Manual Reset essential to effect the pilot

Auto trip on loss of pilot

10.Manual Reset valve with indicator

Indicates the Status of signal presence

Manual Reset Facility

Auto Trip

11.Flow Control Valve

Used for achieving delayed responses

Allows free flow in one direction while restricting flow in other direction

12.Panic Valves

Also called ESD Valves

Are 2 port 2 Position NC type

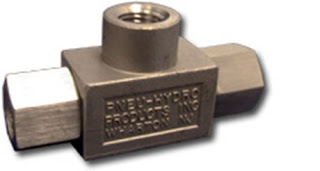

13.Shuttle Valve

Pneumatic equivalent of electronic OR gate

Presence of any one input yields an output.

14.Amot Indicators

Indicates the status of control pressure

Provides first-out and thus easy trouble shooting

Can be used also as a logical component.

15.Check Valves

Also called non-return valves

Allow flow in one direction and blocks reverse flow

16.Relief Valves

Used in Hydraulic circuits

Functions as a back pressure regulator

Relief pressure ranges from 100 to 10,000 PSI

17.Quick Exhaust Valve

Is a 2 position high flow control valve

Assures rapid closure of a Shutdown Valve

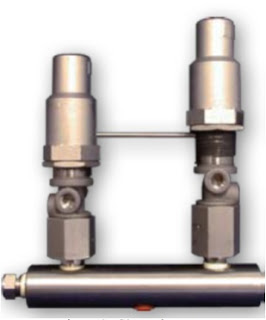

18.Hydraulic dump Valve

Also called hydraulic interface valve

Establishes high pressure hydraulic output

Optional manual override facility available

19.Sigma Master Reset Valve

Used as an interface between shutdown panel and shutdown valve

Often referred to as two phase relay

Capable of maintaining higher supply pressure with lower pilot pressure

Field Reset and Shutdown facility

Blocks inlet when supply falls below 40 PSI

20.Pressure Switch- High , Low

Combination of two 3 Way components

Low switch is connected to NC port while High switch connected to NO port

Standard supply and outlet pressure is 50 PSI

21.Hydraulic Accumulators