RTD Measurement: An Overview

- RTD (Resistance Temperature Detector) measurement is based on the idea that the electrical resistance of a metal changes predictably with temperature.

- The resistance of RTDs, which are frequently made of platinum, increases linearly with temperature. A known current runs through the RTD, causing a voltage drop across it.

- The resistance of the RTD and subsequently the temperature are inversely correlated with this voltage.

- Several wiring layouts, including 2, 3, and 4-wire arrangements, are used to increase accuracy. The most precise arrangement has four wires, which completely eliminates the effects of lead wire resistance.

- For accurate temperature sensing in applications including industrial processes, HVAC systems, and medical devices, RTD measurements are essential in order to account for non-linearities and produce accurate temperature measurements, calibration and compensation are conducted.

The Requirement for Compensation

- In temperature sensing systems, compensation is essential because of the many variables that might change measurement accuracy.

- RTDs and other thermal sensors have inherent problems with lead wire resistance and less-than-ideal properties.

- These problems are reduced through compensation strategies. Readings can be considerably distorted by lead wire resistance, especially in low-resistance sensors.

- Particularly in applications with long wire lengths or low resistance values, this variation has an impact on the level of accuracy of the temperature measurement and can cause large error.

- Accuracy is improved via compensation, which usually involves using 3- or 4-wire designs to eliminate the effect of lead wires. For accurate measurements, nonlinearities in sensor output must also be taken into consideration.

Benefits of 4-Wire RTD Measurement

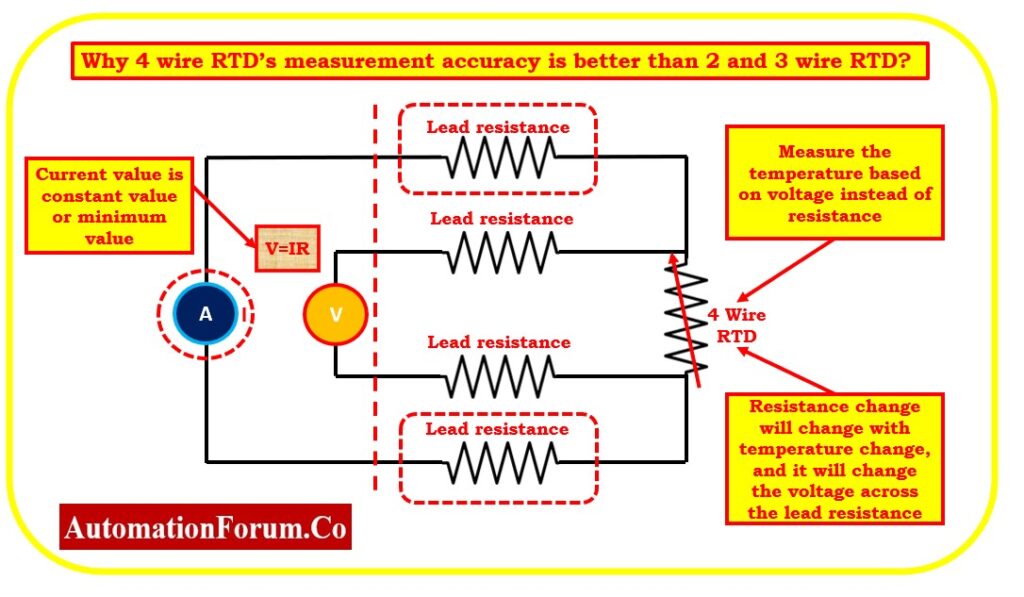

In comparison to the 2-wire and 3-wire configurations, the 4-wire RTD measurement configuration is clearly superior, principally because lead wire resistance is completely eliminated.

With a 4 wire RTD, resistance is not used to determine the temperature. The two lead wires of a four wire RTD are connected in series with a constant current source. We take a voltage reading across the additional two lead wires of the four wire RTD.

Ohm’s law states that V = IR.

The current value is constant (extremely low). The change in resistance, which is dependent on the temperature being measured, will be used to generate the voltage.

As a result, 4 wire RTDs are more accurate than 2 or 3 wire RTDs since they monitor temperature using a voltage signal rather than a resistance.

The four wire RTD circuit schematic is displayed below.

Here are some benefits of the 4-wire configuration:

Lead Wire Resistance Elimination

- Lead wire resistance, particularly with low-resistance RTDs, can have a considerable impact on measurement accuracy in a 2-wire configuration.

- Temperature measurements are extremely accurate because to the 4-wire arrangement, which fully eliminates this influence.

- Two additional wires are utilized only for measuring the RTD element’s resistance in a 4-wire RTD measurement system.

- These wires have very little current flowing through them, and their sole function is to detect the RTD’s true resistance without being influenced by lead resistance.

- Lead resistance mistakes are efficiently minimized by separating the RTD element from the lead wires.

Higher Accuracy

- Out of the three configurations, the 4-wire layout provides the most accurate readings.

- It eliminates mistakes brought on by voltage drops across lead wires by using separate wires for current excitation and voltage measurement, resulting in accurate temperature data.

Performance of Low-Resistance RTDs

- The 4-wire arrangement is essential for low-resistance RTD applications, such as platinum RTDs.

- Accurate readings are practically difficult with 2 or 3-wire setups because the resistance of the lead wires can be equivalent to or even greater than the resistance of the RTD.

Consistency

- The 4-wire arrangement keeps precision even when wire resistances alter as a result of temperature changes or variations in production.

- This consistency is especially crucial in critical processes or applications that require accurate temperature monitoring.

Wide Operating Range

- Because the 4-wire arrangement works well in a wide range of temperatures, it may be used in a variety of environments and applications where temperature accuracy is crucial.

Process Control and Calibration

- Industries needing strict process control and precise calibration, such pharmaceuticals and aerospace, greatly benefit from the accuracy offered by 4-wire RTD measurements.

4 wire RTD vs 2 and 3 wire RTD

| Aspect | 4-Wire RTD | 2-Wire RTD | 3-Wire RTD |

|---|---|---|---|

| Lead Wire Resistance | Effectively Eliminated | Significant Impact | Partially Compensated |

| Accuracy | High Accuracy | Moderate Accuracy | Improved Accuracy |

| Low-Resistance RTDs | Excellent Performance | Poor Performance | Improved Performance |

| Wire Resistance Variation | Minimal Impact | Significant Impact | Moderate Impact |

| Consistency | High Consistency | Moderate Consistency | Improved Consistency |

| Calibration | Precise Calibration | Less Precise | Improved Calibration |

| Temperature Range | Wide Range | Moderate Range | Moderate Range |

| Suitable for Critical Applications | Yes | Limited Suitability | Improved Suitability |

| Complexity | More Complex Wiring | Simple Wiring | Moderate Complexity |