- What is Viscosity?

- Define Absolute Viscosity (Dynamic Viscosity)

- Define Kinematic Viscosity

- List the types of liquids

- What is viscometer?

- Types of Viscometer

- Capillary-tube Viscometer

- Ostwald viscometers

- Ubbelohde Viscometer

- Falling sphere viscometers

- Rotational Viscometer

- Cone on Plate Viscometer

- Electromagnetically Spinning Sphere Viscometer (EMS Viscometer)

- Stabinger viscometer

- Falling Ball Viscometers

- Falling Piston Viscometer

- Oscillating Piston Viscometer

- Vibrational Viscometers

- Bubble viscometer

- Micro-Slit Viscometers

- Frequently asked questions about Viscometers

What is Viscosity?

“Viscosity decreases as temperature is raised.”

Define Absolute Viscosity (Dynamic Viscosity)

Absolute viscosity is a measurement of the internal flow resistance of a fluid. Its unit is poise or centipoise

Define Kinematic Viscosity

Kinematic Viscosity is refers to the ratio of Dynamic Viscosity to density. Its unit is stokes or centistokes

List the types of liquids

- Newtonian Fluid – Fluid with constant Viscosity. Eg: Water, Oil, Benzene

- Non-Newtonian Fluid – Fluid that not having a unique value for viscosity. Eg: Slurries, Paste, Gels, Polymer Solution

What is viscometer?

- A fluid’s thickness can be determined with the help of an instrument is called a viscometer.

- A viscometer provides readings mainly for a single flow pattern. The viscosity of a fluid is measured by the drag it produces when a surface moves relative to it.Under laminar flow, the flow conditions must have a sufficiently low Reynolds number.

Types of Viscometer

Viscometers are divided into four division according to the Japanese Industrial Standard (JIS) Z 8803: capillary tube, falling ball, rotating, and vibration.

1. Standard laboratory viscometers for liquids

- Capillary-tube Viscometer

- Falling sphere viscometers

2. Rotational viscometers

- Cup & Bob Viscometer

- Cone & Plate Viscometer

- Electromagnetically Spinning Sphere Viscometer

- Stabinger viscometer

3. Falling BallViscometer

4. Falling Piston Viscometer

5. Oscillating Piston Viscometer

6. Vibrational viscometers

7. Bubble viscometer

8. Micro-Slit Viscometers

Capillary-tube Viscometer

Working Principle of Capillary-tube Viscometer

- The term “U-tube” viscometer is used to describe this kind of viscometer. It is used to calculate a Newtonian fluid’s viscosity.

- A fluid whose viscosity is unaffected by shear force or rate. The main concept behind it is timing how long it takes a liquid to travel between two places or markers.

- Poiseuille’s law provides the foundation for how the capillary tube viscometer functions.

- This method of measurement compares the time needed for a liquid with a given viscosity to flow through a capillary with a known diameter and length to the time needed for a determined quantity of fluid to do so (usually water).

- Capillary viscometers can detect viscosity at different shear rates, are economical, and only require small volumes of sample fluid.

Formula of Capillary-tube viscometer

?= ? r?t?P/ 8lV

where ,

- r = radius of inside capillary;

- t= time flow;

- ?P=Pressure under which liq. flow;

- L= length of capillary;

- V= volume of fluid flowing

Types of Capillary-tube Viscometer:

- Ostwald viscometers

- Ubbelohde viscometer

Ostwald viscometers

Working Principle of Ostwald viscometers

This viscometer is used to measure viscosity of the liquid with a known density. This instrument is named after philosopher “Wilhelm Ostwald”.

Procedure for viscosity measurement:

• Fill the reservoir’s tube with water until the mark point is reached (mark C)

• Use a suction bulb to suction the liquid from the capillary tube and pull it to mark A.

• Note the time for the liquid falling from mark A (the starting time) to mark B using a stopwatch (ending time)

Formula of Ostwald viscometers

To calculate viscosity:

where

- ?1 = viscosity of the sample solution

- ?2 = viscosity of the water

- p1 = density of the sample

- p2 = density of the water

- t1 = time taken to flow from Mark A to Mark B of the sample in seconds

- t2 = time taken to flow from Mark A to Mark B of the water in seconds

Ubbelohde Viscometer

Working Principle of Ubbelohde Viscometer

- It is a modified version of Ostwald’s viscometer, and it can test high viscosity liquids. This instrument is found by inventor Leo Ubbelohde

- There are two bulbs in this instrument; the first is the reservoir, and the second is the measuring bulb. A capillary tube joins the two bulbs together. In addition, there is a vent for air.

- The reservoir bulb is initially filled with liquid (large bulb located in the lower level). It is important to take precautions to keep the liquid from getting into the air hose.

- The viscometer is submerged in a liquid bath of the same temperature until its internal liquid reaches the same temperature as the bath.

- Afterward, a rubber tube attached to the air tube is used to suction the liquid to the measuring bulb.

- Once the liquid has been transferred, the rubber tube must be sealed to prevent it from leaking back into the reservoir. The liquid is then allowed to fall down when the rubber tube has been loosened. The time it takes for the liquid to cross the two markers at the top and bottom of the measuring bulb is used to calculate the flow rate.

- This viscometer gives accurate readings regardless of the amount of liquid being measured.

Category of Ubbelohde Viscometer

There are two types of viscometers: direct flow and reverse flow. When measuring direct flow, viscometers place the reservoir below the lines; when measuring reverse flow, they place the reservoir above the markings. The marks will be concealed by the liquid, making it impossible to determine when a level has crossed the mark. In order to calculate the amount of opaque or staining liquids these classifications are required because the liquid will cover up the marks.

This permits the viscometer to have several marks, allowing for the timing of the time needed to reach the third mark right away, producing two timings, and allowing for the computation of the determinability of the viscosity to be done later, ensuring reliable results.

Formula of Ubellohode viscometer

Flow rate, Q= V/T

Q is inversely proportional to the time between the marks.

As p is the hydrostatic pressure which is proportional to the density of the fluid

Therefore,

where

- Kv is viscometer constant

- t’ is correction time.

Similarities & differences in Ostwald & Ubbelohde Viscometers

Similarities

- The two instruments have a U-shaped form.

- Each of these instruments is equipped with two glass bulbs.

- Capillary tubes are used in both of the instruments.

Differences

Ostwald viscometer is appropriate for measuring liquids with low to moderate viscosity, whereas Ubbelohde viscometer is appropriate for measuring liquids with high viscosity.

Advantages of Capillary Viscometer

- Accurately measure viscosities of a wide range of fluids

- Lightweight and portable

- Low cost

- Easy to use wide range of capillary tubes can be used with a single viscometer

Disadvantages of Capillary Viscometer

- There is no one tube that works for every possible viscosity, and the simplest models can only be used with transparent fluids.

- One of the challenges is that capillary tubes are notoriously difficult to disinfect.

Applications of Capillary Viscometer

- The viscosity of a large variety of fluids can be measured with a capillary viscometer. Typical examples include things like motor oil, adhesives, sealants, and lubricants.

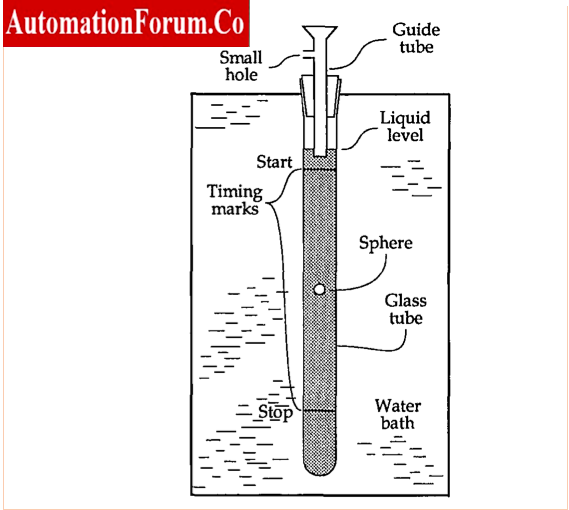

Falling sphere viscometers

Working Principle Falling sphere viscometers

The fluid is stationary in a vertical glass tube in the falling sphere viscometer. Stokes’ law forms the basis of this viscometer.

A sphere with known dimensions and density is allowed to float in the fluid. By measuring the time it takes to pass between two tube markers, one can determine the final velocity, if the choice is made properly.

Electronic sensing is a practical solution for transparent fluids. If you know the terminal velocity, the size and density of the sphere, as well as its density, you can apply Stokes’ law to calculate the fluid’s viscosity.

Formula in Falling sphere viscometers

The terminal velocity, often referred to as the settling velocity, is attained when the frictional force combined with the buoyant force exactly balances the gravitational force if the particles are falling in the viscous fluid by their own weight. The following formula yields the final settling velocity (or terminal velocity)

Where

This kind of gadget is also appropriate for use on ships.

Advantages of Falling sphere Viscometer

- High shear equipment

- Accuracy can be increased when steel ball bearings with various diameter are used.

Disadvantages of Falling Sphere Viscometer

- Can be maintenance intensive

- Replacement parts can be costly

Rotational Viscometer

Working Principle of Rotational Viscometer

- These viscometers are suitable for both Newtonian and non-Newtonian systems.

- The fluid being measured for viscosity is sheared between two surfaces, one of which rotates and the other of which is stationary.

- The rotational deflection of the cylinder, which occurs when either the outer or inner cylinder rotates at a constant speed, serves as a gauge for the viscosity of the liquid.

- The sample is sheared in the area between the inner and outer walls of the cup. The sample causes the bob to turn because of a viscous drag.

- The ratio of the resultant torque to the sample’s viscosity.

Procedure in Rotational Viscometer

- Put the sample into the beaker, while tilting it to avoid air bubble that might affect result of viscosity.

- With the motor off, attached the spindle at a 45 degree angle to prevent air bubbles.

- Move the gear up and down until the fluid and is level with the spindle’s immersion groove

- Operate and enter the key codes to start rotating the spindle and take the date on the screen displayed

Advantages of Rotational Viscometer

- It is useful for describing shear-thinning and time-dependent behavior and can measure the viscosities of opaque, settling, or Non-Newtonian fluids.

- The rotating component’s speed can be simply changed.

- Frequently connected to computers to facilitate automated measurement.

Disadvantages Rotational Viscometer

- It can be fairly pricey.

- Large and immovable in many cases.

Types of Rotational Viscometer

Couette type Rotational Viscometer “Rotating-cup”

- The cup is rotated while the bob is constant. The viscous drag on the bob produced by the liquid results in a torque which is proportional to the viscosity of the liquid.

- Examples: Mac Michael Viscometer – Rotating cup and stationary bob

Searle type Viscometer

- In searle type viscometer, the bob is rotated while the cup is kept constant.

- Examples: Stormer viscometer, Brookfield viscometer

Couette Viscometer

- In this viscometer, the cup is rotated while the liquid’s drag on the bob creates a torque that is inversely proportional to the liquid’s viscosity.

- As shown below, the two cylinders are concentric and have an annular clearance that is filled with fluid.

- The outside cylinder rotates at a steady speed while the internal cylinder is fixed.

- It is determined how much force is required to shear the fluid between the cylinders.

- Cylinder’s velocity can be adjusted to measure how the fluid’s viscosity varies as the shear rate increases. For various fluids, various cylinders with a variety of radial clearances are employed.

Formula in Rotational Viscometer

The dynamic viscosity (?) can be estimated from the formula:

where

- rb,rc is the radius of the inner and outer cylinder respectively [m];

- M is the shear torques on the inner cylinder [Nm];

- w is the angular velocity [rad/s];

- d is the immersion depth of the inner cylinder [m];

- k is the viscometer constant [m3]

Cone on Plate Viscometer

A flat plate and a conical surface make up the cone on plate viscometer. These surfaces can both be rotated. The fluid is forced into the space between the cone and the plate, where the cone angle maintains a constant shear rate. With the fluid sample in between them, a low angle cone rotates against a flat type.

Formula of Cone on Plate Viscometer

The dynamic viscosity (?) can be estimated from the formula

where

- r is the radius of the cone [m];

- M is the shear torques on the cone [Nm];

- w is the angular velocity [rad/s];

- alpfa is the cone angle [rad];

- k is the viscometer constant [m3]

Advantage of Cone on Plate Viscometer

- Very little fluid sample volume is needed for the test

- The temperature of the fluid sample is adjusted while tests are being conducted. This also has running preheated or Chilled external fluid through the viscometer plate.

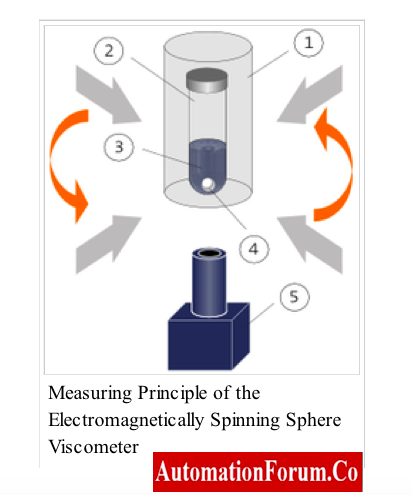

Electromagnetically Spinning Sphere Viscometer (EMS Viscometer)

The electromagnetic interaction-driven spinning of a sphere is used by the EMS Viscometer to gauge the viscosity of liquids.

A spinning magnetic field is created by two magnets connected to a rotor. In a little test tube is the sample (3) that needs to be measured (2). An aluminium spherical is located inside the tube (4). The tube is positioned so that the sphere is in the middle of the two magnets in a temperature-controlled space (1).

Eddy currents are created in the sphere by the spinning magnetic field. The magnetic field and these eddy currents then interact through a Lorentz process, creating torque that rotates the sphere. The magnetic field’s strength, rotational velocity, and viscosity of the sample surrounding the sphere all affects to how quickly the sphere rotates. A camera (5) placed underneath the cell keeps an eye on the sphere’s movement. The angular velocity differential between the magnetic field’s (B) and the sphere’s (S) angular velocity determines how much torque is delivered to the sphere. Thus, the connection between (BS)/S and the liquid’s viscosity is linear.This new measuring principle technique was found by Sakai et al.

Advantages of EMS Viscometer over Capillary & Rotational Viscometer

- No cleaning is necessary

- Measurements can be carried out in a controlled environment

- There are no measuring errors due to evaporation.

- This is the ideal solution for samples that are only available in small quantities

- Quick temperature control of the small sample container

- No cleaning required after measurement.

How EMS Viscometer is different from other rotational viscometers?

Samples are inexpensive and disposable. In a sealed sample vessel, the measurements are carried out. Only very small sample quantities are needed for the EMS Viscometer (0.3 mL).

Stabinger viscometer

Working Principle of Stabinger viscometer

Kinematic viscosity determination accuracy can be combined with a large measuring range by adapting the traditional Couette type rotational viscometer.

- Kinematic parameters can be obtained by integrated density measurement from the oscillating U-tube technique.

where

- V is the Kinematic Viscosity [mm2/s]

- ? is the dynamic viscosity [mPa.s]

- r is the density (g/cm3)

Working of Stabinger Viscometer

- The rotor is propelled by the shear forces of the rotating fluid & an eddy current brake is created by the copper housing and magnet inside the rotor. Driving and retarding forces establish an equilibrium rotor speed, which is a clear indicator of the dynamic viscosity.

- A Hall effect sensor counts the frequency of the rotating magnetic field to measure speed and torque without making physical contact.

- This enables a large measuring range from 0.2 to 30,000 mPa•s and a highly accurate torque resolution of 50 pN•m with a single measuring system.

Advantages of Stabinger Viscometer

- Kinematic viscometer with an integrated density measuring cell that is extremely precise.

- The temperatures range between 15°C and 100°C.

- This provides high efficiency with green and environmental protection, and does not require thermostat bath.

- Simply inject the sample using a syringe to begin the measurement.

- Simple cleaning and safe handling without leaks or breakage.

- Low maintenance.

- Factory-adjusted and ready for use right away.

Application of Stabinger Viscometer

- Provide certified for density & Kinematic viscosity in analyzing diesel fuel.

- Determines the viscosity of crude oils in petroleum industry to determine when it’s time for an oil change.

- Ensures the purity of jet fuel.

- To determine the viscosity of samples containing volatile ingredients.

- To the measurement of viscosity in lubricating oil.

Falling Ball Viscometers

Working Principle of Falling Ball Viscometers

There are also many additional varieties of viscometers available, each based on a different measurement basis. The “Falling Ball Viscometer” is the instrument that is most frequently used in laboratories. A steel ball is dropped into a glass tube that has been filled with the fluid being evaluated. After that, the measurement is made by counting the time it takes the ball to fall between the first and second timing marks that are etched on the tube. The accuracy of the time measurement is 0.1 [sl. Additionally, the determination of viscosity changes under pressure can be done with this viscometer.

Formula in Falling Ball Viscometer

The dynamic viscosity can be estimated from the formula

F is the correction factor

F = 1 – 2.104(d/D) +2.09(d/D)3 – 0.9 (d/D)5

where

- d is the diameter of the ball [m],

- D is the internal diameter of the tube [m)

Falling Piston Viscometer

Working Principle of Falling Piston Viscometer

The founder of Falling piston viscometer is Austin Norcross. It is also known as the Norcross viscometer.

The principle of viscosity measurement based on a piston and cylinder combination. This viscometer is durable, sensitive industrial device and robust.Substance being measured is pulled through the clearance (gap) between the piston and the cylinder wall into the space below the piston as it is regularly lifted by an air lifting mechanism.

The assembly is held up briefly before falling to shear the liquid being measured. The viscometer is sensitive enough to measure thixotropic liquids.The duration of fall is used to compute viscosity from the piston cylinder clearance.

The viscosity controller determines viscosity from fall time. The controller can set time-of fall to centipoiseor cup seconds (also known as efflux cups).

Advantages of Falling Piston Viscometer

- This instrument is common for industrial application since it is easy to repeat, requires no upkeep, and is unaffected by flow rate or outside vibrations.

- The operating concept is flexible and adaptable and it is perfect for environments involving process control.

Oscillating Piston Viscometer

Working Principle of Oscillating Piston Viscometer

A measurement chamber and a piston with magnetic effect make up the sensor. A sample is initially delivered into the thermally controlled measuring chamber where the piston is located in order to obtain measurements. Electronics use a regulated magnetic field to move the piston in an oscillatory motion inside the measurement chamber. The piston journey places a shear stress on the liquid (or gas), and the viscosity is calculated by timing the piston’s movement.

According to Newton’s Law of Viscosity, the viscosity is calculated using the construction parameters for the annular gap between the piston and measurement chamber, the strength of the electromagnetic field, and the piston’s journey distance.

Advantages of an oscillating piston flowmeter

- Installation can be carried out in either a vertical or horizontal position, or even at an angle.

- It is not necessary to run straight pipes before and after the flowmeter.

- Viscosity fluctuations do not significantly affect the oscillating piston flowmeter. It is therefore perfect for applications where the temperature is variable.

- It has a lengthy operating life under normal working conditions.

Disadvantages of oscillating piston flowmeter

- The liquid must be clear and free of suspended particulates, which could jam or harm the revolving piston in the chamber and alter flow data.

- Installing a filter before the flowmeter prevents costly malfunctions if the application fluid contains solids.

- The higher the liquid viscosity, the higher the pressure loss.

- The pipe must always be entirely filled to avoid reading inaccuracies.

Application of oscillating piston flowmeter

- Laboratory applications for small sample viscosity and micro-sample viscosity measurement have been developed using the oscillating piston viscometer technology.

- It has been modified to assess viscosity at high temperatures and pressures in both laboratory and process settings.

- The viscosity sensors have been scaled for a broad range of industrial applications, including small size viscometers for use in compressors and engines, flow-through viscometers for dip coating processes, in-line viscometers for use in refineries, and many more.

- The use of oscillating piston viscometers in academic laboratories studying gas viscosity is growing as a result of improvements in sensitivity brought forth by modern electronics.

Vibrational Viscometers

Vibrational viscometers measure the damping of an oscillating electromechanical resonator to determine a fluid’s viscosity. The resonator often oscillates transversely or in torsion (as a cantilever beam or tuning fork). The amount of damping imposed on the resonator increases with viscosity.

Advantages of Vibrational Viscometer

- Quick and accurate measuring is feasible.

- Because the vibration approach just slightly perturbs the sample liquid, there is little energy delivered to it.

- Because of the oscillator’s low thermal capacity, interference from the measurement with the sample substance can be minimized

Disadvantages of Vibrational Viscometers

- The lack of a specified shear field in the vibrational instrument renders it unsuitable for measuring the viscosity of a fluid whose flow behavior is not known.

- Rugged industrial systems called vibrating viscometers are used to detect viscosity in a process environment. A vibrating rod is the sensor’s active component.

- The viscosity of the fluid in which the rod is submerged affects the vibration’s amplitude.

Application of Vibrational Viscometers

- These viscosity meters can measure high-viscosity fluids (up to 1,000 Pa•s), including those containing fibers, and clogging fluid.

- These viscometers are currently regarded by many industries as the most effective way to test the viscosities of a variety of fluids

Can we prefer Rotational Viscometer for measuring clogging fluid?

Rotational viscometers need more regular calibration after heavy usage, are unable to monitor blocking fluid, and also it requires extra maintenance of instrument.

Bubble viscometer

The measurements can change because of variations in buoyancy caused by the bubble’s shifting form in the tube, despite the fact that this approach is remarkably exact. There is no significant miscalculation as a result, though.

Application of Bubble Viscometer

Bubble Viscometer can be used in kinematic viscosity of well-known liquids like resins and varnishes may be efficiently determined.

Micro-Slit Viscometers

Viscosity measurements is performed utilising flow through a slit. To overcome the wall shear stress in a viscous flow through a circular pipe, pressure is necessary.

Slit flow simulates actual application flow circumstances, such as drug injection or inkjetting, and has the advantage of not requiring entrance or exit pressure drop corrections.

Advantages of Micro Slit Viscometer

• Calculates the absolute viscosity of fluids, including Newtonian and non-Newtonian.

• An enclosed system eliminates sample evaporation and air interaction.

• Measuring is possible with small sample volumes.

• Laminar flow is enabled by low Reynolds numbers even at high shear rates.

Application of Micro Slit Viscometer

Micro slit viscometer is used for measuring blood viscosity over a Wide-Ranging Shear Rate

Frequently asked questions about Viscometers

What is meant by Rheometer?

A rheometer is a device used to measure the response of a dense fluid (a liquid, suspension, or slurry) to applied forces.

How rheometer differ from viscometer?

Rheometers measure a fluid’s response to applied shear or stress, which may reveal information about the elasticity and viscosity of the material. But viscometer measures viscosity of material under one flow condition.

Which Industries Benefit from Viscometers and Rheometers?

Industries that uses Viscometers

- Industries like food industry, the chocolate factory, and the baking process uses viscosity testing to guarantee that quality is maintained.

- The rotating viscometers are used by the chemical industries, the biofuels industry, the paint industry, the petroleum industry, and the pharmaceutical sector.

Industries that uses Rheometer

- Manufacturing industries for coatings, polymers, petrochemicals,

- Industries like medicines, Cosmetics & household goods are rely heavily on rheological characterization of materials

What are the errors and factors affecting viscometer?

Error in Viscosity are caused by Alignment

If the surface tension of the fluid allows sample to “leak” out of the flow cell, the inaccuracy caused by misalignment towards the unbounded edges of the capillary (from left to right) can be rather severe.

Factors Affecting Viscosity

Molecule size: Solutions with large particles exhibit high viscosity. That is, the viscosity is directly proportional to the size of the molecules.

Molecules Shape:Spherical molecules exhibit low viscosity due to their shape.

Force:Large intermolecular forces result in more viscous materials.

Temperature:A gas becomes more viscous as its temperature rises. With an increase in temperature, fluid viscosity decreases.

Why measuring viscosity is important?

- Viscosity is utilized to characterize a product constituent. A lot of typical polymers for these ingredient classes are frequently chosen or specified based on their viscosity in their solutions in different solvents.

- Viscosity, as a characteristic of a suspension or solution and in determining inventiveness. Whether particles in a suspension will settle at a specific rate, for instance.

- It also has a significant effect on determining the quality of various fluids used in various applications.

What are the need in measurement of viscosity?

- Uses include determining inherent viscosity,

- Determining light fuels

- Controlling polymerization,

- Determining the flow of various solvents through HPLC or GC pumps

- Determining or researching the physical characteristics of liquids.

What is meant by Dip Cups?

These cups help paint makers and users quickly estimate efflux times for paints and comparable fluids.

What is meant by Flow Cups?

Many applications do not require paint system viscosity. The efflux time in seconds is practical. It is measured using various flow cups according to international/national standards. A defined volume of liquid flows through these cups. Measuring reproducibility depends on

- The cup’s measurement accuracy

- A constant measurement temperature

- The liquid’s Newtonian flow behavior

What is meant by Efflux time?

It is the amount of time needed to drain the vessel’s contents.