What is Profibus?

Profibus is an industrial digital communication and it can be used to do bidirectional communication for the industrial field device. Profibus is widely used in the industrial sector because of its fast I/O data transferring capability. It is a multi-drop network which means that many devices can be connected on a single cable to communicate. Profibus means process Fieldbus, it is a widely utilized open field bus. It is used in several industries to achieve process control and it is utilized in large assemblies. If it is connected once then it can carry out the communication in an efficient manner. Profibus is really good to do time-critical applications and also to do complex communication tasks.

The major feature of the Profibus is that the same protocol can be used no matter what kind of transmission medium or technology is used.

How does Profibus Communicate?

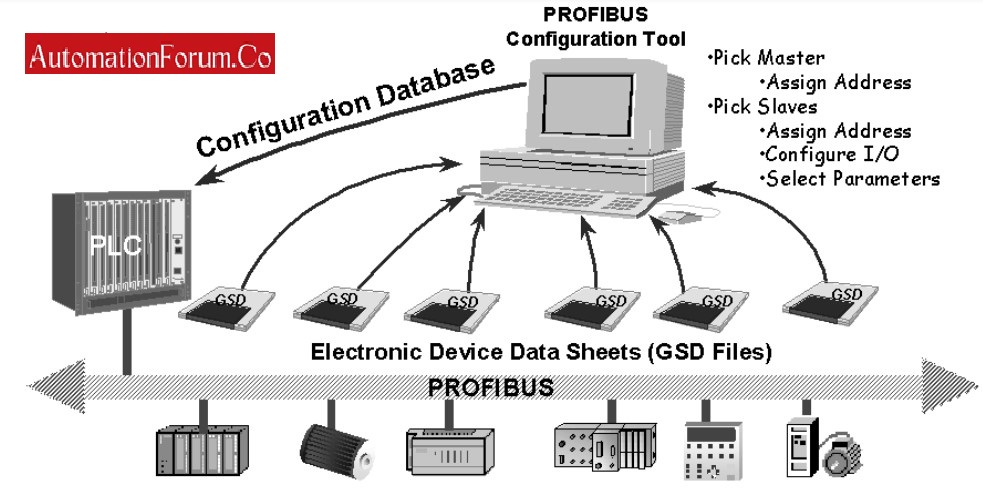

Profibus communicates in the master-slave method, the data transmission would be carried out through wires. It can be used to transmit data over several kilometers. The data would be transmitted in a master-slave method. Master would be a control device in an industrial process and it can transmit messages without any request while the slave would be the field device in the industrial process such as transmitters, sensors, actuators, etc. The slave would receive messages from the master and slave would only transmit messages in case there is any request from the master.

Profibus network utilizes three layers in the OSI network the Physical, data link, and Application layer.

- The application layer is to handle different types of messaging in the Profibus.

- The Data link layer would is utilized to carry out the master-slave communication this layer would specify which slave would receive the message.

- The physical layer is the way in which the communication takes place in the Profibus it could be RS485 for twisted paired wiring, fiber optic, and Manchester bus power can also be utilized to achieve the communication.

Profibus communication protocol:

Profibus DP (Distributed peripherals):

In this type of communication, high-speed data transmission can be achieved. In this network, we can connect up to 32 devices. More than a hundred repeaters can be used for long-distance transmission. This type of communication would be achieved by using four wires, two wires would be utilized for power and the other two would be used for the signal. This type of Profibus protocol is mostly used for general automation applications. It is used for short-distance communication and mostly it would be used indoors. Mostly it would use RS485 or fiber optic cable to achieve the data transmission.

Profibus PA (Process Automation):

This is a high-performance network cable and it would consist of several thousands of I/O points. Data transmission through these I/O points can be communicated within milliseconds. This type of communication protocol is extensively used because of its high-speed communication. This protocol is developed to replace the 4-20mA transmission. It utilizes the two-wire connection to achieve data transmission. This communication protocol can be used outdoor and it can be utilized in harsh environmental conditions, unlike the Profibus DP. This protocol would check the equipment through the process control system. Profibus PA can be defined as a standardized Profibus DP. In this type of Profibus protocol, only weak current flows through the intrinsic safe circuit in the bus cables and due to that, there won’t be any spark if there is any fault.

In Profibus PA there would be less number of cables when compared to the Profibus DP. All the field devices would be separately wired to the control device I/O in Profibus DP. In the case of Profibus PA, there would only be a single cable that would connect to all the field devices thus less wiring is required and that’s why it can be used in the hazardous environment.

What are the advantages of having Profibus-based communication?

• High-speed field communication can be achieved

• It utilizes the OSI model and due to this several varieties of devices from different vendors can communicate with each other

• Profibus not only does the communication it can also determine the device parameter, calibration, performance data, etc.

• It is a globally accepted communication standard

• It is mainly designed for the process industry

• It is a two-wire connection and it would carry both the power and the data

• Functionality would be improved

• Productivity of the plant will be increased

• Downtime can be reduced

• Hardware costs can be reduced

• Transmitters, Actuators, valves, etc can be connected in a network

• Servicing costs would be lowered due to the simpler cabling

How to do the Profibus commissioning?

Acceptance measurements are the measurements that would determine if the communication cable is properly laid and if the cable length is proper. It shows if the measurement range is proper or not and a lot more.

Bus commissioning:

• Do the visual inspection and acceptance measurements

• Configure the system

• Make sure the address settings of the Profibus stations are proper

• Commission the master and slave

• Test the input and output signals

• Create an acceptance checklist

What are the major factors that must be considered while installing the Profibus DP?

• Profibus cables and connectors should be used

• Make sure that the devices used in the network are not more than 32, including couplers, repeaters, and OLM.

• Check if the segment length is in contrast with the baud rate

• Spur lines must be removed

• Powered termination must be done on both ends of the segment

• Make sure that there is no wire swapping

• Make sure that there is no short circuit or break in the cable

• Check if the address is properly set or not

• Make sure that the communication to the device can be easily carried out.

What are the major applications of Profibus?

• Factory Automation – Vehicle manufacturer, bottling plants, Warehousing systems, Switchgear, Hollow glass production, etc.

• Process Automation – Chemical Industry, Petrochemical industry, Paper & textile industry, Food products, etc.

• Drive technology – Machine tools, Packing machines, etc.

• Safety Applications – Vehicle assembly, Machine tool building