What is Pressure Switch?

Pressure switch is a device that closes the electrical contact when a certain set fluid pressure has been reached in its input. It is designed to make contact either a rise in pressure or a fall in pressure. Most pressure switch use diaphragm or bellow as a sensing element. The deflection of this sensing element is used to actuate one or more switch contact to indicate an alarm or initiate a control action. A pressure switch is consequently utilized to make sure that the operation of equipment is proper and the safety of personnel. Due to the different roles that pressure switches play in countless residential and industrial systems, variety of switches currently exist.

What is the working principle of pressure switch?

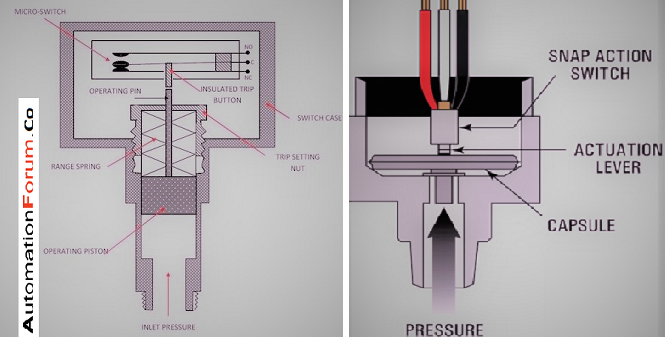

Most pressure switch use diaphragm or bellow as a sensing element. The deflection of this sensing element is used to actuate one or more switch contact to indicate an alarm or initiate a control action. The working of pressure switch is same as relay switch. The above figure shows the sectional view of the pressure switch. The input (inlet pressure) is applied to the bottom of the operating piston. Due to this inlet pressure the piston is forced upwards against the range spring. The tension of the range spring can be adjusted so that it is compressed at required pressure or set-point value. When this set-point pressure is reached, the operating pin will hit the trip button on the micro?switch and change it over. The normally open (NO) contacts will become closed and the normally closed (NC) will open. By adjusting the trip setting nut, the pressure at which the micro?switch changes over is set .This trip setting nut adjusts the tension of the range spring. For example, if the nut is turned clockwise the pressure trip will be higher. The main parts of pressure switch are,

- Micro-switch: Micro switch is used to make or break the electrical circuit when pressure switch operates. For low voltage and low current operations, micro-switch with gold contacts are used. For higher voltage and higher current applications micro-switch with silver contacts are used. As shown in the cross section, it is a single-pole double- throw switch (SPDT). The switch is made of one normally open (NO) contact and one normally closed (NC) contact. NO become close and NC become open when pressure contact actuates.

- Insulated trip button: The insulated trip button causes the normally open (NO) and normally closed (NC) contacts to switch when the pressure switch actuates.

- Operating pin: As shown in figure, the operating pin is attached to the operating piston. When the inlet pressure changes, the piston actuates. As a result the operating pin either moves up or moves down. When it moves up, it make contact with the trip button. When it moves down, it breaks the contact with trip button.

- Trip setting nut (range screw): The trip setting nut also called the range screw is used to adjust the set-point of the pressure switch. This function is done by changing the amount of compression in range spring. If the range spring is more compressed by the trip setting nut, the set point of pressure switch will be high.

- Range spring: Range spring is a pre-compressed spring. The pressure at which the switch operated is determined by the amount of force generated by range spring.

- Operating piston: Operating piston is in contact with the operation of pressure switch. The process pressure acts on the area of operating piston. Due to this, it generates the force which opposes the range spring.

- Housing or switch case: Housing or switch case is defined as the enclosure which contains the micro-switch and other accessories. Switch housings are generally available in either aluminium or steel.

What are types of pressure switch?

Pressure switches are broadly classified into two,

- Electromechanical pressure switch: Electromechanical pressure switches employs several types of sensors. It increases the relative accuracy and longevity of switches.

- Solid state pressure switch: The function of solid state pressure switch includes not only the normal operation as open/close, but also includes digital displays and provides digital output or analog output. Solid state pressure switch have one or more switch points.

How to calibrate pressure switch?

The above figure shows the calibration of pressure switch. The required equipments are multimeter, pressure switch, hand pump, pressure gauge.

Materials required for calibration of pressure switch:

- Multimeter

- Pressure switch

- Hand pump

- Pressure gauge

- Data sheet

What are the procedure for calibrating pressure switch?

- First remove the pressure switch from the process.

- Connect air supply and multimeter in continuity to check the change.

- Then slowly increase the pressure till it reaches the set point.

- The multimeter beeps when NO (normally open) to NC (normally closed) and we can write the readings.

- Now we can decrease the pressure slowly till the beep sound stops. The point is falling pressure.

- Repeat the process and calculate the difference between rising and falling pressure which is known as the Dead band.

What are the advantages of pressure switch?

- Pressure switch is used in daily life situations such as controlling the amount of water pumped into a washing machine, or the correct operation of pool filters and air conditioning systems.

- The advantage of using in industries, for comparison utilizations can range from controlling the pressure in a boiler.

- Pressure switches are used to ensure the safe operation of various terrestrial and marine hydraulic systems.

These are the advantages of pressure switch. Due to the different application, different types of pressure switches are currently available.

What are the applications of pressure switch?

The application of pressure switch are the following,

- Pressure switches are widely used in oil and gas industries.

- Pressure switches are used in press machine, plastic molding injection, etc.

- Pressure switches are used in various medical equipments such as to monitor the pressure of incoming gas in oxygen delivery systems.

- The Hydraulic type and pneumatic type pressure switches are used to control the air bellows in trucks and to control brake pressure in trains.

- Pressure switches are used in automotive applications as monitoring engine oil, power steering and transmissions.

- Explosion proof pressure switches with heavy housings are used in flammable atmosphere to prevent ignition.