- Directional Control Valve

- How to Turn on the Directional Control Valves?

- What is the function of a Directional Control Valve?

- What are the types of Directional Control Valves?

- Classification of Directional Control Valves

- Various Types of Directional Control Valves

- Directional Control Valve Operating Methods

- Frequently asked Questions:

Directional Control Valve

- The directional control valve is used to direct the flow of fluids. Fluids can be either liquids or gasses .

- In industries, directional control valves are widely used to allow fluid to flow through a system.

- It is difficult to manually adjust every control valve at the correct time.

- It changes the position of internal components in a hydraulic or pneumatic system to control fluid flow.

- By opening and closing its ports, allows or restricts fluid flow to the actuator.

- There is a distinction between the directional control valves used for liquids and those used for gasses .

- Because liquids exert high pressure, the directional control valve must be heavier and more robust in design.

- For gas applications, the directional control valve is made of aluminum.

How to Turn on the Directional Control Valves?

- There are numerous ways to operate directional control valves.

- The process of moving the valve element from one position to another is known as actuation.

There are four types of actuation in a directional control valve:

- Manual

- Mechanical

- Solenoid-Operated

- Pilot-Operated.

What is the function of a Directional Control Valve?

The operation of directional control valves is determined by several factors, including

- Spool Type,

- Spool Positioning,

- Control Method,

- Special Features.

If all of these elements are properly chosen, proper flow regulation can be achieved. The operation of the control valve is described in the sections that follow.

What are the types of Directional Control Valves?

- Check valves

- Pilot-operated check valve

- Three-way and four-way valves

- Manually-actuated valve

- Pilot-actuated valve

- Solenoid-actuated valve

- Shuttle valve

Classification of Directional Control Valves

Based on the type of construction

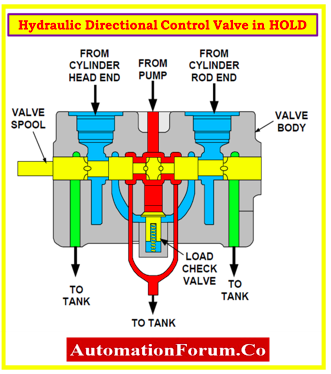

- The most basic configuration of a directional control valve is a spool inside a cylinder, with the spool’s movement allowing and stopping the flow of fluids through it.

- Other types include sliding spools, rotating spools, and poppets.

Sliding Spool

- In this type, the spool will slide axially in a bore, and the spool is also classified as a closed center and open center spool.

- When the valve is in the normal position, the closed center spool blocks all valve ports from each other, whereas the open center pool allows all valve ports to communicate with each other.

Rotary Type

- The spool rotates about its axis in this type.

- The rotary valve is made out of a stem that is round and has channels or passageways. The ports in the valve body are connected to the channels in the stem. The valve rotates rather than moving to the right or left.

- The valve in the diagram on the left links the pump to the cylinder’s rod end. The tank receives the oil from the head end. The oil in the rod end flows to the tank when the valve is turned 90 degrees, connecting the pump to the head end.

- A four-way valve is represented by the rotary valve. Rotary valves can, however, also be two- or three-way valves. When working under low pressure, the rotary valve is used.

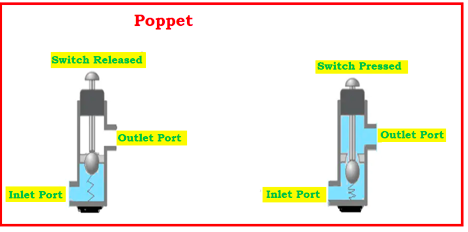

Poppet Type

A piston or ball that moves on and off the seats

Based on the Number of Ports

2-way valves

- This type of valve can direct the flow of the pump to one of two circuit paths.

- The spool used in this valve would be a two-way two-position valve that is normally open.

3-way valves

- This type has three ports, most of which are spool-designed rather than poppet-designed.

- These valves can either prevent or allow fluid flow from the inlet to the outlet.

- These valves have three inlets: a pressure inlet, a system outlet, and a return to the tank.

4-way valves

- These valves are capable of controlling double-acting hydraulic cylinders as well as bidirectional motors.

- Four-way DCV valves have four ports, two of which are outlet ports and the other two are pressure inlets and return to the tank.

Based on the number of Switching Positions:

- The position is represented by the square box.

- The directional control valve symbol is made up of a number of square boxes that are adjacent to each other based on the number of positions.

- One, two, or three positions are available.

Based on Actuating Mechanism

- Manual, mechanical, electrical, pneumatic, and hydraulic methods are used to operate the directional control valves, as shown in the table below.

- The spool inside the directional control valve changes position and controls the fluid flow when the actuator is pressed.

Based on the Fluid Path

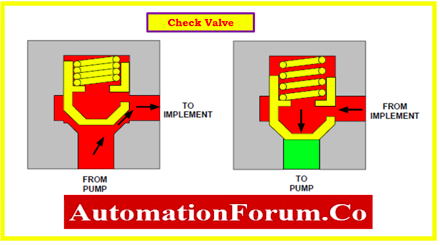

The Check Valve

- The check valve is a type of directional control valve that allows fluid to flow in one direction while blocking fluid flow in the opposite direction.

- Because it has two ports, it is known as a two-way valve.

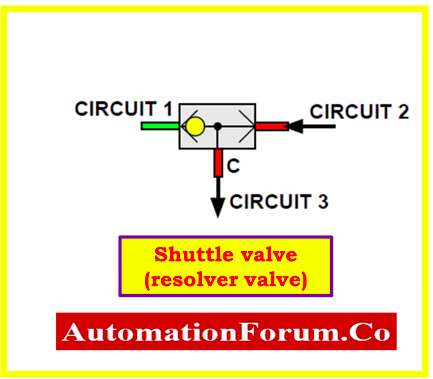

The Shuttle Valve

- Shuttle valves are used to connect two alternate flow sources to a single branch circuit.

- There are two inlets and one outlet on these valves.

- The flow travels from the inlet to the outlet, so because this valve has two inlets, the inlet with the high-pressure flow will reach the outlet.

- If one of the inlets has a high flow pressure, the ball will move to the other side and the flow will reach the outlet.

Various Types of Directional Control Valves

- 2/2 way valves are used for ON/OFF fluid supply. It can be opened or closed normally.

- Single-acting actuators are typically controlled by 3/2-way valves. It can be opened or closed normally.

- For double-acting actuators, 4/2, 4/3, 5/2, and 5/3-way valves are commonly used.

DCV and Fluid Pressure Control Valves

- A flow path to the cylinder actuation is provided by directional control valves, as is a return path to the tank.

- The fluid pressure is controlled to perform various functions such as pressure relief, sequence valve, and counterbalance valve.

Pressure Relief Valve

- Also known as a relief valve or a safety valve.

- It keeps system pressure from building up and causing equipment damage or serious hazards.

- Normally, pressure relief valves are closed-type valves.

- Between the pump and the direction control valve is the pressure relief valve.

- There are two types of pressure relief valves:

- Direct-Operated

- Pilot Operated.

Sequence Valve

A sequence valve is used to ensure that a specific pressure level is maintained in one branch line with the circuit’s first consumer. Later, in a sequential fashion, supplied to the second consumer.

Counter balance Valve

- A counterbalance valve is used to prevent the cylinder from moving too quickly.

- It is resistant to rapid changeover.

- In earth-moving equipment, a counterbalance valve is used.

- It holds the load for a short period of time, similar to lifting a tractor or truck trolley.

Directional Control Valve Operating Methods

1. Manual Valves

- Manual valves are operated by levers or paddles that require force to open and close.

- Occasionally, the spring force is required to reposition the valve.

- Some manual valves, on the other hand, use a lever or an external pneumatic or hydraulic signal to return the spool to its original position.

2. Mechanical Valves

Mechanically operated valves are more prone to wear and tear due to the use of cams, wheels, and rollers to apply force.

3. Hydraulic Valves

- Hydraulically operated directional control valves are far more durable than other methods of operation.

- Furthermore, because they operate at much higher pressures than a pneumatic directional control valve, they are designed to be more precise.

Frequently asked Questions:

What are the distinct varieties of Directional Control Valves?

- In general, directional control valves are classified according to the number of ports.

- Depending on the number of ports in a system, there are three main types.

- The operating positions of 2-way, 3-way, and 4-way valves differ, allowing for different channels of movement.

What does a 3/2 Direction Control Valve mean?

A 3/2-way valve has three ports and two positions that can be controlled pneumatically, mechanically, manually, or electrically with the help of a solenoid valve.

They are used to control a single-action cylinder, drive pneumatic actuators, blow-off, pressure release, and vacuum applications, among other things.

What does a 4/3-way Directional Control Valve mean?

A directional control valve with four ports and three positions, or flow paths, is represented by the 4-Way Directional Valve block.

What is the most common DCV?

A 4/3-way valve, which has four working ports and three spool positions, is the most common directional control valve.