- What is a control system?

- What is the importance of the control system In industrial process?

- What Is a feedback control?

- What is an example of a feedback control system?

- What are the advantages of feedback control?

- What are the disadvantages of the feedback control?

- What is Feedforward control?

- What is an example of feedforward control?

- What are the advantages of feedforward control?

- What are the disadvantages the feedforward control?

- Key Differences Between Feedback and Feedforward Control Systems

- Major difference between Feedback and feedforward control?

- What is feedforward plus feedback control?

What is an industrial process?

The major objective of an industrial plant is to create high-quality products. These products would be sold at a good price too, in order to sell these products at a good price it should have good quality. Several raw materials would be utilized to create a product and this operation is called a process. If the process is carried out in a good manner, then the quality of the end products would be really good. In order to control the industrial process, we would require a good control system.

What is a control system?

A Control system would be capable to control the industrial process, it can maintain the required condition in a physical system by adjusting several variables in a system. We can define the system as the combination of several devices and all these devices would act in an equal manner to achieve the requirements. In a control system, there would be a lot of components interconnected as a system and it would provide the required response.

What is the importance of the control system In industrial process?

- Control system is an integral part of many manufacturing industries

- Most of the industrial process is carried out by utilizing the automatic control system

- We can give several commands to the industrial process via the control system

- It would control the variations in parameters

- Disturbance rejection

What Is a feedback control?

This method would utilize the values of the controlled variable to vary the values of the manipulated variable. The feedback loop would measure the process variable and this measurement would be sent to a controller to compare it with the set point. The system would take the necessary action to make the process variable equal to the set point or the required value.

The below image is an example of the feedback control, transmitter would measure the fluid temperature, and based on that it would open the hot steam valve to maintain the fluid temperature. This type of control would correct the problem after it has occurred, we can use feedback control to do the manual and automatic control. In this type of control, it would sense, compare, compute, and correct the process variable.

What is an example of a feedback control system?

An example of a feedback control system is the thermostat-controlled heating system in a home. In this system, the thermostat continuously monitors the actual room temperature and compares it to the desired setpoint. If the room temperature falls below the setpoint, the thermostat sends a signal to turn on the heating system. Once the room temperature reaches the setpoint, the thermostat signals the system to turn off.

This process relies on feedback because the system adjusts based on the actual temperature (the feedback signal) to maintain the desired level, responding only after a deviation from the setpoint is detected

What are the advantages of feedback control?

- It won’t sense the changes in parameters

- It won’t be able to determine the modeling errors

- It doesn’t need to determine or require the measured value of the disturbance

What are the disadvantages of the feedback control?

- It would only take action after the system is affected by the disturbance

- It is not effective in case of a slow process

- In the case of the closed loop response it can create instability

What is Feedforward control?

In feedback control, it would utilize the output of a process to make changes in the input of the system. This type of control would utilize the direct measurement of the disturbance variables to vary the values of the manipulated variable. This type of control is called predictive control in this control it would determine the load disturbance and this disturbance would be controlled before it affects the process.

We can describe a feedforward control as a control that takes place before it is affected by the disturbance. This type of control would anticipate the disturbance in the process variable and would take proper actions before it affects the process variable. The image which is shown below is an example of the feedforward control. In this, the flow transmitter would open or closes the hot steam valve according to the amount of cold fluid that passes through the flow sensor.

What is an example of feedforward control?

An example of feedforward control is the control of temperature in an industrial heating system. In this system, if the outside air temperature is expected to drop significantly, the feedforward controller adjusts the heating system in advance to compensate for the upcoming colder conditions.

This proactive adjustment is made before the room temperature actually starts to drop, ensuring that the system maintains a consistent indoor temperature, preventing any lag that would occur if the system waited for the temperature to drop before responding (as in a feedback system).

This approach is often used in processes where disturbances can be predicted and compensated for in advance.

What are the advantages of feedforward control?

- It would act before the system is affected by the disturbance

- It would be stable in case of the closed loop response

- It would be effective for the slow system

What are the disadvantages the feedforward control?

- It would require the measurement of disturbance for its operation

- It won’t be able to handle the unmeasured disturbances

- It would easily determine the variations of process parameters very easily

- Proper knowledge of the process control is required

Key Differences Between Feedback and Feedforward Control Systems

- Timing: Feedback control systems adjust process inputs based on past performance, while feedforward control systems adjust inputs based on expected future performance.

- Use of Information: Feedback control systems rely on the error signal to make adjustments, whereas feedforward control systems use information about expected conditions to modify process inputs.

- Response Time: Feedback control systems may have a longer response time as they wait for the error signal to occur, while feedforward control systems anticipate problems and adjust inputs before they arise, resulting in a shorter response time.

Major difference between Feedback and feedforward control?

Feedback vs Feedforward control

| Feedback control system | Feedforward control system |

|---|---|

| It would only act in case the process is affected by the disturbance | Acts before the disturbance affects the process |

| Accurate | Less accurate because if there are any changes in the system |

| Response would be slow | Quick response |

| Closed loop control system | Open loop control system |

| Air conditioner, Electric Iron | Examples – Washing machines, Traffic lights |

| Complex system | Not as complex as feedback system |

| Costly due to its complexity | Economical |

| It can handle severe disturbances | It won’t be able o handle the severe disturbance |

| It can handle variations in its environment, or in case of aging in certain components | It won’t be able to handle the variations in the process environment or any device. |

| It won’t be able to do any predictive control | Predictive control can be done |

| It cannot be used with the process that has large time delays | It can be used with the process that has large time delays |

| Maintenance would be high | Less maintenance |

| It won’t be easy to construct | Easy to construct |

What is feedforward plus feedback control?

In order to avoid the difficulty of anticipating the load disturbance in a feedforward system, feed back system can be used with it. So in this type of control system the combined input from the feedforward and feedback system would be given to the controller.

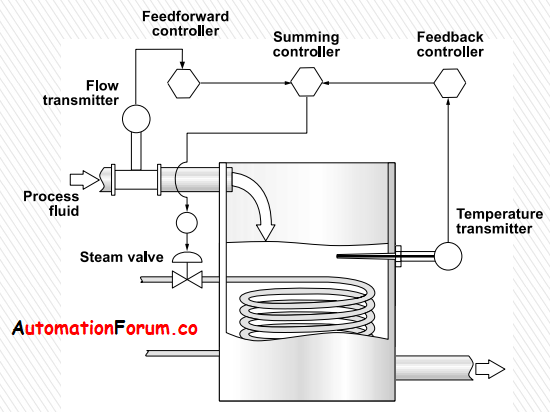

The below image is an example of feedforward plus feedback control. In this, the flow transmitter and the temperature transmitter would provide the details to control the hot steam valve.

Feedforward plus feedback control is a combination of both feedforward and feedback control strategies to leverage the advantages of both while mitigating their individual disadvantages. In this combined system, the feedforward control handles anticipated disturbances before they affect the process, while the feedback control corrects any errors that are not predicted by the feedforward control.

In a feedforward plus feedback control system, sensors monitor both the process variable (as in feedback control) and the disturbance variable (as in feedforward control). The control actions are taken based on both the feedback loop, which corrects errors after they occur, and the feedforward loop, which anticipates disturbances and adjusts the process beforehand. This makes the control system more robust, accurate, and effective in maintaining process stability.