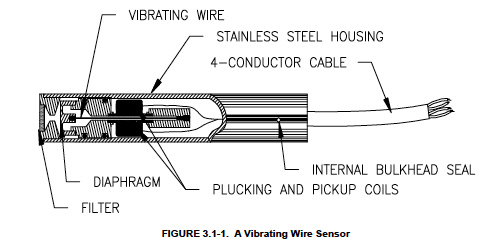

The Vibrating Wire sensor consists of an electronic oscillator circuit which causes a wire to vibrate at its natural frequency when under tension. The principle is similar to that of a guitar string.

The vibrating wire is located in a diaphragm. As the pressure changes on the diaphragm so do the tension on the wire which affects the frequency that the wire vibrates or resonates at. These frequency changes are a direct consequence of pressure changes and as such are detected and shown as pressure.

The frequency can be sensed as digital pulses from an electromagnetic pickup or sensing coil. An electronic transmitter would then convert this into an electrical signal suitable for transmission.

This type of pressure measurement can be used for differential, absolute or gauge installations. Absolute pressure measurement is achieved by evacuating the low-pressure diaphragm. A typical vacuum pressure for such a case would be about 0.5 Pa.

Temperature variations require temperature compensation within the sensor, this problem limits the sensitivity of the device. The output generated is non-linear which can cause continuous control problems

Advantages:

- Good accuracy and repeatability

- Stable

- Low hysteresis

- high resolution

- Absolute, gauge or differential measurement

Disadvantages

- Temperature sensitive

- Affected by shock and vibration

- Non-linear

- Physically large