What is the need for connectors in industrial automation?

The industrial process is carried out by transmitting signals, so connectors are used to transmit signals from cables to industrial equipment or machinery. So the connectors which are used in the industry must be able to cope with its environment. There could be a lot of electronic components in an industrial application and these components would be affected badly if the temperature or the moisture level varies beyond a specified limit. So, in this case, heavy-duty connectors are used. We must choose connectors according to our industrial process if the connectors are used where there is a chance for machine vibrations and shock then we should use the connectors that should have a rugged design and it must have a proper casing too.

What are the major requirements for an industrial connector? How to select connectors for industrial applications?

- It should be able to handle extreme conditions like temperature, pressure, shocks, etc

- Small size

- Less maintenance

- It must be waterproof

- It should operate in vacuum conditions too

While selecting a connector we must check its ingress protection rating and by checking this we could determine how the connector would perform for a specified industrial process.

What are the major types of connectors used for industrial automation?

- Coaxial connectors

- D-sub connectors

- Fiber optic connectors

- Rj45 connectors

- USB connectors

- Display connectors

- SCSI connectors

1. Coaxial connectors (RF)

The coaxial connectors can be used to connect and disconnect transmission lines, systems, and components at microwave frequencies. These connectors would provide RF links in communications, and also in the test and measurement field too. These connectors can be used to access circuits, testing, inter-connecting, and also packaging the components into a system. We must choose a coaxial cable according to the impedance, operational frequency, insertion loss, reflection performance, environmental requirements, and also we need to consider the size and cost. While selecting this connector we must make sure that the impedance of the connector matches the source and load so that maximum power transfer can be achieved.

2. D-sub connectors

The D sub is the short form for D subminiature, we can see these connectors in many industrial computers and components. The D sub connectors are used with low current circuits such as data signal, position sensor feedback, micro-switches, and trim motors. These connectors are used in the control unit and also in the display unit. The major advantage of the D sub connector is that each D sub connector is unique so that we can reduce the risk of mismatch. These connectors have a D shape and the male and female D sub connectors have the reverse numbering as shown in the above image.

3. Fiber optic connector

The fiber cable does the transmission of light instead of the electrical signal. Due to this, the terminations should be accurate, the major purpose of the fiber optic connector is to align microscopic glass fibers properly so that the communication can take place very easily. The fiber connector has three major parts the ferrule, connector body, and coupling mechanism.

Ferrule

This is a thin structure that holds the glass fiber, this would provide a tight grip on the fiber

Connector body

This could be a plastic or metal structure that holds the ferrule

Coupling mechanism

This section of the connector would be useful when the connector is attached to another device, this part would hold the connector in place when it is connected to another device.

Different types of fiber optic connector

ST type

This type of fiber optic connector has a straight tip, this type of connector uses a 2.5mm ferrule it could be a plastic or metal body. These connectors are used widely for many fiber optic applications. This connector stays in place with a twist-on/twist-off, bayonet-style mechanism. Now, these connectors are replaced by smaller and denser connectors.

SC type

This is a subscriber connector and it also has a 2.5mm ferrule to hold a single fiber. This type of fiber cable is connected and disconnected by the push-on/pull-on mechanism.

FC type

This type of fiber connector is mostly used for telecommunication applications and it provides a nonoptical disconnecting feature. These connectors are designed with threaded coupling for durable connections. In this type of connector, the ferrule is PC finished to a pre-radius and this would ensure the low back reflection.

LC type

This type of fiber optic connector has a retaining tab mechanism and it is an RJ45 connector. The connector body has the squarish shape of the SC connector. These connectors are mostly held together in a duplex configuration with a plastic clip.

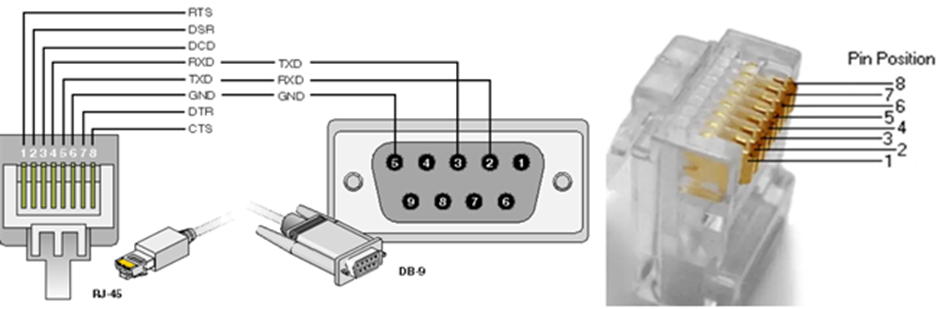

4. RJ45 connectors

This is an 8 position 8 conductor modular connector that is mostly used for the data network such as Ethernet. RJ stands for registered jack, and mostly it is used for ethernet networking. These connectors are wider than the RJ-11/12 connector which is used in the telephone. These connectors are used to do the connection from a patch panel to a network switch and also it can be used to connect a computer’s NIC to a data port. We can connect a computer to LAN by using RJ45.

5. USB

USB is the short form of universal serial bus, it is used to do short-distance digital communications. We can connect USB connectors to the USB ports in the computer and thus we can transfer digital signals over the USB cables. Mostly a USB port has 4 to 24 pins for the transmission of the power and data. There are various USB connectors in different shapes and sizes.

USB speed rate

Low speed USB 1.0 – 1.5Mbit/sec

Full speed USB 1.1 – 12Mbits/sec

High speed USB 2.0 – 480Mbit/sec

Super speed USB 3.0 – 4.8Gbit/sec

6. Display connectors

Different types of display connectors

DVI

DVI stands for the digital visual interface is a video interface standard that would provide very high visual quality on digital display devices such as computer displays, LCDs, etc. The DVI port has a different pin layout to differentiate between various kinds of connectors. This port is the only video port that supports both HD analog and digital video signals over the same connector.

HDMI

HDMI stands for the high-definition multimedia interface, this is a compact audio/video interface to transmit uncompressed digital data. HDMI is the most popular HD video interface which is available, it would only transmit digital video signals. The latest version of the HDMI 2.1 can transmit 10K video at 120HZ or 4k video over 480HZ.

Display port connectors

Display port is a digital display interface, this interface is used to connect a video source to a display device like a computer monitor. It can also be used to carry audio and other forms of data. Display source is an open-source alternative to HDMI, and unlike HDMI, you can create and integrate display ports into your device without paying a commission to its creators. The HDMI port was developed by a group of companies so using the HDI is costly due to the fact that the device manufacturers have to pay royalties for its use. A display port is capable to transmit digital video signals up to 4K at 60HZ frequency. The newest display port can support HDR and up to 8K video output on a compatible device.

HDMI vs Display ports

| SL NO | HDMI | DISPLAY PORT |

| 1 | Bandwidth is low when compared to display port | Higher bandwidth, due to this the cable can transmit more signal |

| 2 | Can’t connect multiple monitors to the computer | It can be used to connect multiple monitors to the computer |

| 3 | 100Kbps data rate | 1Mbps-720Mbps data rate |

| 4 | There is no data link training and it has fixed amplitude | Link training would allow the source to adjust the amplitude and pre-emphasis based on the feedback sink |

| 5 | There is no link maintenance | Link maintenance |

| 6 | There is no stream management | Stream management |

| 7 | There is no power management feature | Power management feature is available |

| 8 | Costlier than the display port | Economical |

| 9 | Synchronous display timing adopted from analog video standards | Micro packet data structure |

| 10 | The digitized video would be sent at a display pixel rate (3 data pairs) | 8B:10B data coding, embedded clock in each data pair and this would enable data channel scalability. It would also eliminate separate pixel clock signal |

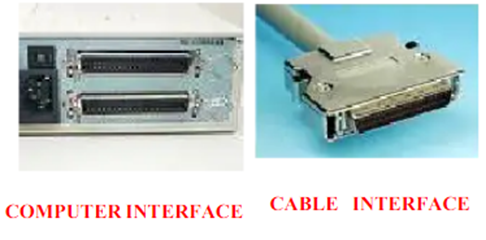

7. SCSI

SCSI stands for small computer system interface and it is used to connect and transfer data between the computer and the peripheral devices. Mostly SCSI is used for hard disks and tape drives but it can also connect a wide range of devices such as scanners and CD drives. SCSI has 50 pins. It can be used to do the peer-to-peer interface. Mostly all the devices are connected to the SCSI bus in a similar manner. We can connect 8-16 devices to a single bus. There could be any number of hosts and peripheral devices, but there should be at least one host.