- Generally, the term maintenance in industries means increasing assets productivity & reducing failure to avoid accidental damage.

- Both these maintenance activities deliver better advantages in that these activities shrink the failure rate of machines and enhance the safety of expensive materials.

- Work orders for each maintenance sort are organized before the maintenance task to ensure both sorts of scheduled maintenance

- Usually, the maintenance is classified into Predictive Maintenance, & Preventive Maintenance.

What is Predictive Maintenance?

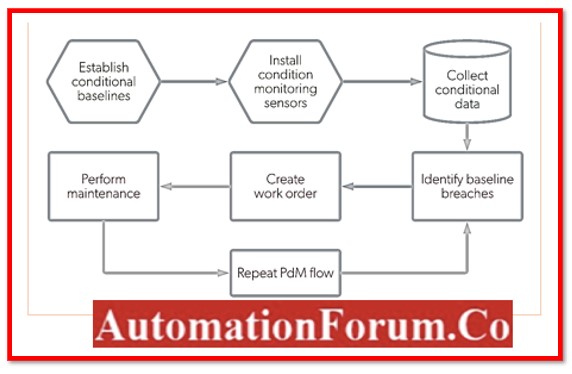

- Predictive Maintenance is organized on resource conditions.

- Predictive Maintenance minimizes the cost of labor and material required.

- The term predictive maintenance activity is quite similar or interrelated to preventive maintenance,

- Because some preset conditions are essential for this preventive maintenance

- In our human health comparison, this element is comparable to screenings or measures suggested for an individual who is in greater danger for a particular illness due to adopted or lifestyle habits.

- Technicians trigger a predictive maintenance protocol for a convenient schedule for repair to avoid future damage or accidents in case a part of the machine performs abnormal parameters.

- For this, a Computerized Maintenance Management System (CMMS) is advisable because this system delivers essential measurements and data that are required to adopt the smart resolution.

- This CMMS reduces unexpected maintenance tasks, reduces the cost required for maintenance, and builds a strong maintenance program for monitoring equipment and system to stay in running mode.

- However, establishing a predictive maintenance strategy involves a significant investment in terms of money, training, and resources. These costs tend to be acceptable to companies that effectively carry out a preventive upkeep program.

Advantages of Predictive Maintenance

- Proactive

- The actual problem is identified before they are addressed

- Shorter downtime

- Inventory efficiency is good

- Based on contemporary data, this report provides a wide range of alternatives for maintenance practices.

- Avoiding catastrophic breakdowns and spotting emerging issues with machines and systems.

- The automatic capability to track the mean-time-between-failures, (MTBF) is a side benefit of predictive maintenance.

- Eliminate unnecessary maintenance

- Reduce lost production caused by failures

- Reduce repair parts inventory

- Increase process ef?ciency

- Improve product quality

- Extend operating life of plant systems

- Increase production capacity

- Reduce overall maintenance costs

- Increase overall pro?ts

Disadvantages of Predictive Maintenance

- More complex

- Not as scheduled as preventive maintenance

- Requires advanced technology to share data with a centralized system

- Needs additional training

What is Preventive Maintenance?

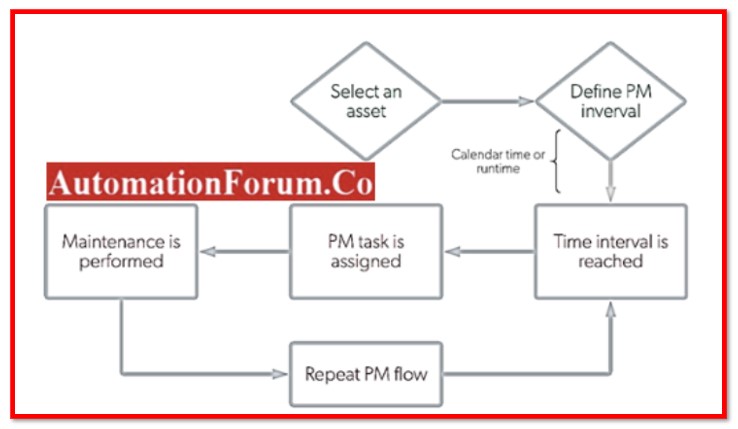

- Preventive maintenance is organized on a regular basis.

- Preventative maintenance is simpler to execute.

- Preventive maintenance is collated for a physical check-up annually.

- Technicians execute this maintenance task to avoid future breakdowns or emergency maintenance issues even in smooth-running conditions.

- Preventive maintenance is a physical checkup to prevent equipment failures and extend resource span like we consult a doctor to prevent illness or lengthen our life.

- Additionally, preventive maintenance balances the expanse cost, & return costs of resources.

- Maintenance managers having better experience should make a smart resolution for the preventive maintenance of machines

Advantages of Preventive Maintenance

- Proactive

- Limits unplanned downtime

- Increases equipment lifespan

- Efficient for experienced staff.

- Enhance capital equipment productive life.

- Reduce critical equipment breakdowns.

- Allow better planning and scheduling of needed maintenance work.

- Minimize production losses due to equipment failures.

- Promote health and safety of maintenance personnel

Disadvantages of Preventive Maintenance

- Increases planned downtime

- Improved inventory management for replacement parts.

Predictive Maintenance Vs Preventive Maintenance

| Predictive Maintenance | Preventative Maintenance |

| Triggers on Time | Triggers on Condition |

| This is conducted to predict the occurrence of failures | This is conducted to avoid assets from unexpected damages. |

| This is performed as per the schedule | This is performed on a routine basis. |

| Here it is not required to stop the main function of the resource, because diagnostics of machine can easily be performed even if the resource is executing its usual functions. | The resource’s downtime must be increased, which means required functions can be stopped. |

| Maintenance is performed when potential flaws are detected. | Maintenance is performed even if potential flaws may not be detected. |

| Complexity is more and is much more difficult than preventive maintenance. | Complexity is very less and is quite easier than predictive maintenance. |

| Less expensive than preventive maintenance. | Highly more expensive than predictive maintenance. |

| It avoids unpredictable expenses, hence no more investment. | It doesn’t avoid unpredicted expenses, hence needs investment. |

| Requires less time for simple periodic inspection and maintenance. | Requires more time for simple periodic inspection and maintenance |

| Cost Savings in Predictive Maintenance 25% to 30% | Cost Savings in Preventive Maintenance is about 12% to 18% |

| Predictive maintenance is typically carried out to foresee potential breakdowns so that they can be avoided. | Preventive maintenance is often carried out to guard against sudden asset breakdown. |

| Only when probable problems are found in this does maintenance take place. | Even if probable faults are not detected in this, maintenance is carried out. |