Feedback Control

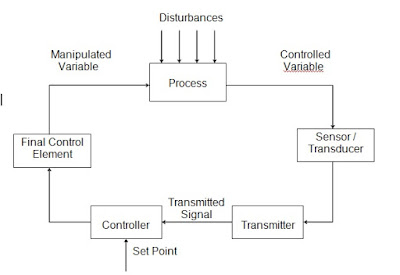

Feed-back control is gathering information on the controlled variable and comparing it to the set point; making a decision based on that comparison; and taking action to eliminate any differences between the controlled variable and the and the set point

In feedback control, there is a constant flow of information in a closed loop. All of the instruments which work together in the loop to control a process are called the feedback control loop.

Elements of the Feedback control loop

Instruments are used in the feedback control loop to: monitor and measure process parameters, relay information, determine needed action, cause the action to happen, or take action. The instruments used in a feedback control loop are listed below:

|

The Sensor

or

Transducer

|

Monitors and measures the process parameters you want to control, which is the controlled variable

For example, a thermocouple used in a heating process to sense the temperature in a vessel

|

|

The Transmitter

|

Relays information about the controlled variable (sensed by the sensing instruments) to a controlling instrument or other instruments in the loop

Using the temperature example, the thermocouple output is picked up by the transmitter which sends a signal to the controller.

Before the signal can be sent, the transmitter first transforms the sensed value into a signal which can be transforms this into a 4-20 milliampere electric signal which the controller can receive.

|

|

The Controller

|

Determines needed action by comparing information received from the transmitter to the set point (the desired value of the controlled variable which is entered in the controller). If there is a difference between the set point and the actual value of the controlled variable (the deviation), the controller sends a signal to the final control element.

For example, if the controller determines that the temperature in a vessel is too low. The controller sends a signal to the final control element to increase heat to the vessel.

|

|

Takes action to adjust the manipulated variable in the process. This adjustment drives the value of the controlled variable back toward the set point

The final control element in our temperature example could be a gas valve which opens to allow more gas (manipulated variable) in the dryer to increase the temperature (controlled variable)

|

Other Instruments that support a control loop

In addition to sensors, transmitters and controllers, and final control elements, there are other instruments which support the feedback control loop. These are instruments that provide information to the operator or assist in the control of the process. Typical examples of these instruments are:

|

· Recorders

|

Recorders keep a continuous record of the value of the controlled variable so that operators, instrument technicians, and managers can evaluate the process over a period of time

|

|

· Indicators

|

These are lights and displays which graphically show a value of the controlled variable so that operators and instrument technicians can see at a glance what is occurring in the process.

|

|

· Alarms

|

Alarms tell the operators and instrument technicians when the value of the controlled variable is out of limits. They alert operators and technicians to problems or potential problems.

|

|

· Interlocks

|

Interlocks are devices which will not allow one part to function unless another part is functioning. Interlocks are frequently used as safety measures or to protect equipment

|