Table of Contents

- Applications of SCADA

- What is SCADA?

- Applications of SCADA include

- 1. Electricity Generation, Transmssion, and Distribution Systems:

- 2. Manufacturing Industries or Plants:

- 3. Food & Pharma Production:

- 4. Telecom & IT-based systems:

- 5. Water Treatment Plants, Sewage Treatment Plants, & Supply Management:

- 6. Traffic Controls:

- 7. Lift & Elevator Controls:

- 8. Buildings & Society Environments:

- 9. Oil & Gas Systems:

- 10. Mass Transit & Railway Traction:

- SCADA in Power transmitting Systems

- Some of the applications are

- Benefits of SCADA for Power Systems

- The general features of a SCADA substation system are

- Additional features of the substation control system

- SCADA for Power Utility Network

- Features of Power Network Utilities

- Objectives of SCADA

- The application of SCADA

- SCADA Advantages

- Frequently asked Questions

Applications of SCADA

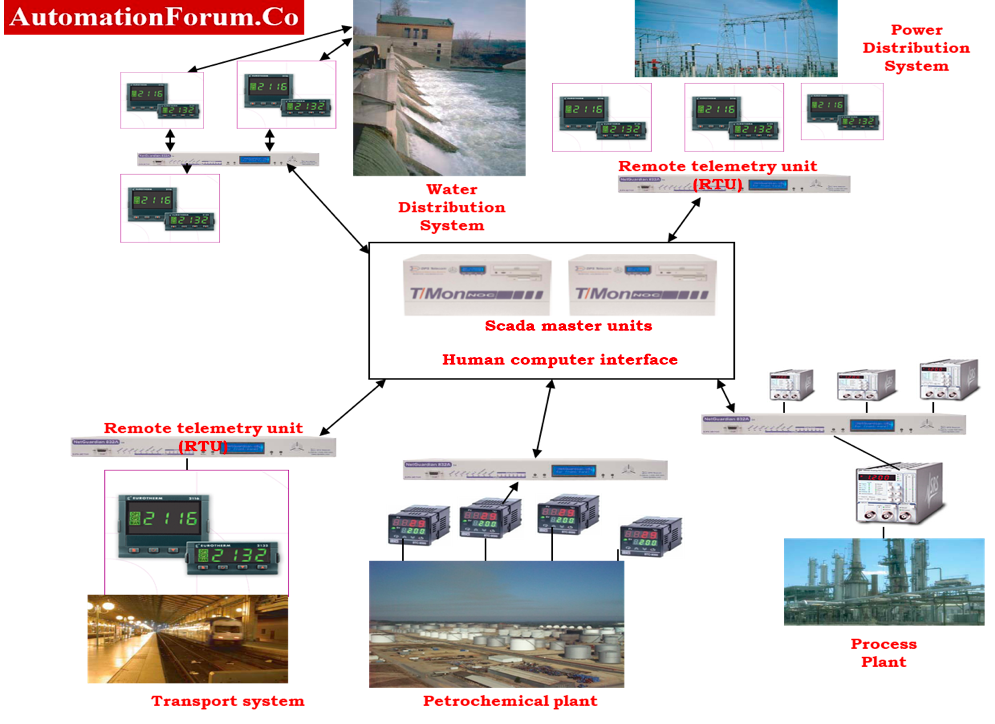

What is SCADA?

- SCADA stands for Supervisory Control and Data Acquisition.

- SCADA is a computer-based system to analyze real-time production data. SCADA monitors and manages alarms, and programs for automatic responses triggered by system parameters.

- SCADA system is a very essential tool for process automation.

- It helps to be aware of potential network issues.

- It makes informed decisions to respond accordingly on time.

- It is a type of remote monitoring system to manage and control equipment to eliminate human error.

- SCADA is widely used in various sectors such as chemical, gas, water, communications, and power systems.

- SCADA is a combination of software and hardware elements for process industries to

- Process Control & monitor in real-time from a remote location

- Analysis & calculation of complex processes & maintaining control signals accordingly.

- Data Acquisition, Historical Data Logging, Archiving & Retrieving

- Trend & Alarm Generation

- Recipe Management in Process & Chemical Industries

- Report Generation

Applications of SCADA include

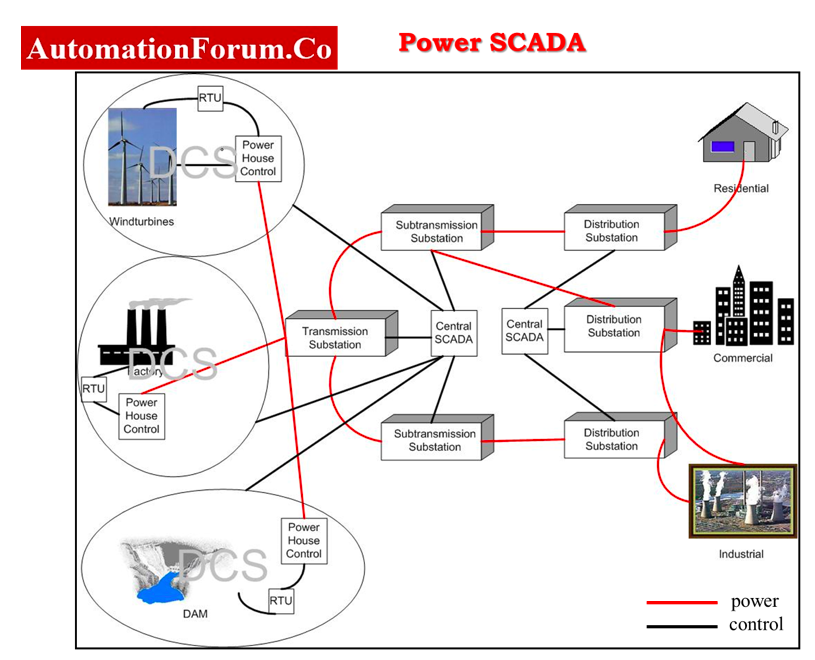

1. Electricity Generation, Transmssion, and Distribution Systems:

- SCADA systems are used in electric power generation plants, transmission areas, and distribution systems.

- SCADA systems monitor each and every phase of the generation of electricity from fuel input to electrical output.

- SCADA systems can also be used to monitor and control electrical switchboards, Grids, and transmission lines.

- SCADA monitors and controls the actual electrical power being transmitted over long distances.

- This system responds to load fluctuations instantaneously.

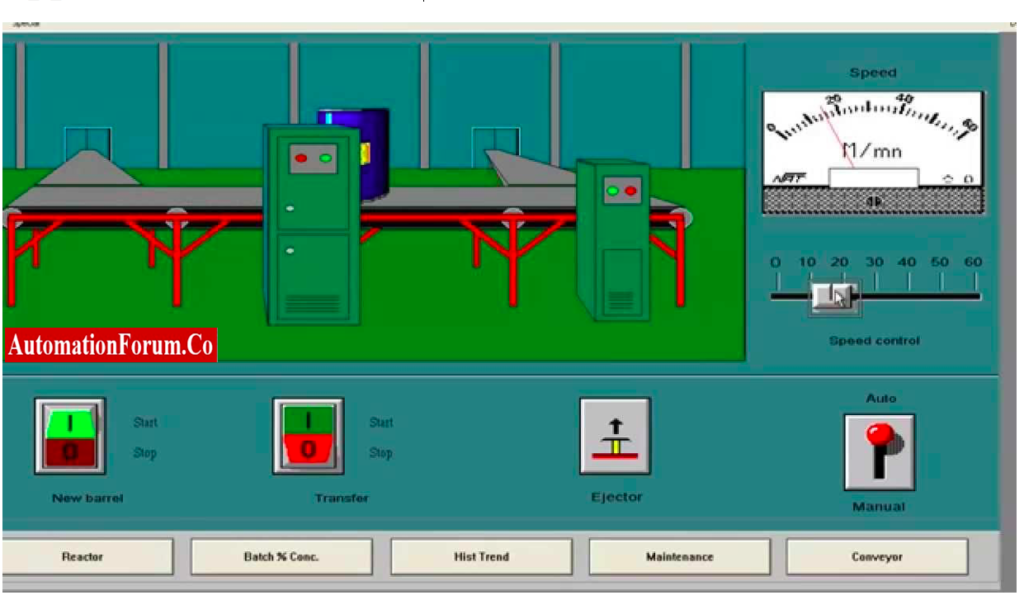

2. Manufacturing Industries or Plants:

- A SCADA helps in managing various raw materials or inventory items, to control automated systems in synchronous order.

- SCADA precisely controls every plant operation to ensure all systems run smoothly and meet productivity targets.

- SCADA tracks the number of units produced, & measures process values such as temperature, pressure, and humidity at various production phases.

- It also controls assembly line robots.

3. Food & Pharma Production:

- SCADA system monitors and controls all stages of the production unit.

- Controls the exact mixture of required ingredients.

- Monitors the time and temperature required to manufacture & process food & beverages or pharmaceutical products.

- SCADA documents data to prove the production meets the industrial standard and government regulations.

4. Telecom & IT-based systems:

Managing different Radio Frequency based systems, communication mediums, and large communication systems such as logging data and information through an antenna using a SCADA system is very easy.

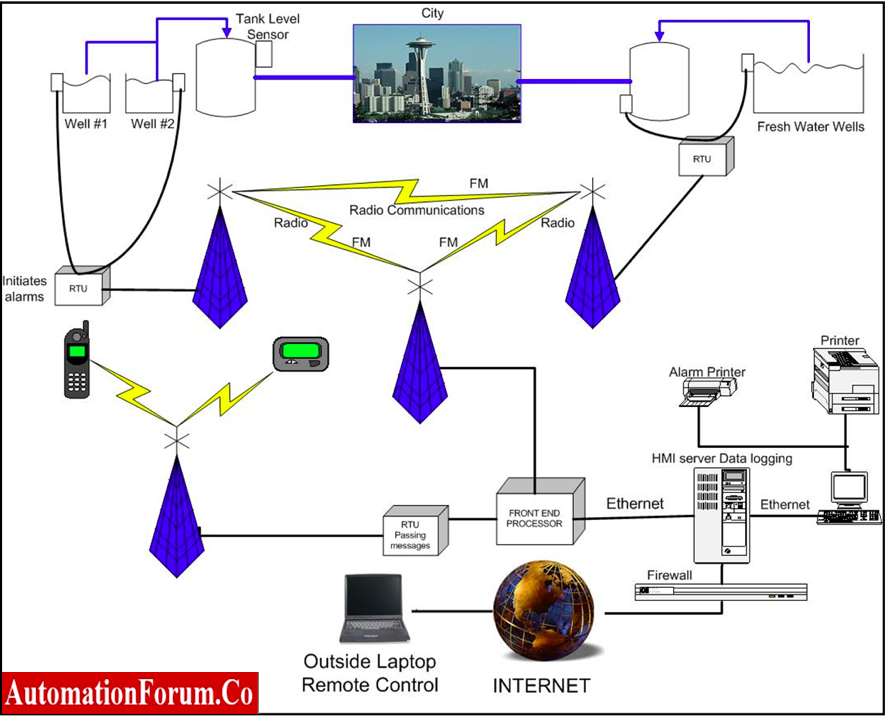

5. Water Treatment Plants, Sewage Treatment Plants, & Supply Management:

- Municipal Corporations and other government sectors are using SCADA for monitoring, controlling, and regulating the level and flow of water in dams & reservoirs.

- SCADA system monitors and controls the water being pumped from bore wells and treated at WTP.

- This system controls flow rate sensors and contaminant sensors.

- This controls the booster pump to regulate the water pressure supplied to the process.

6. Traffic Controls:

- In metropolitan cities, SCADA regulates traffic signal lamps, detects signals out-of-order, & controls traffic flow.

- In railway systems, on-road systems, & airlines the traffic flow is controlled by the SCADA system.

7. Lift & Elevator Controls:

SCADA system can also be used to lift and control elevators in commercial malls and in large industries.

8. Buildings & Society Environments:

Facility managers use SCADA to control High Voltage AC, refrigeration units, lighting, and entry systems.

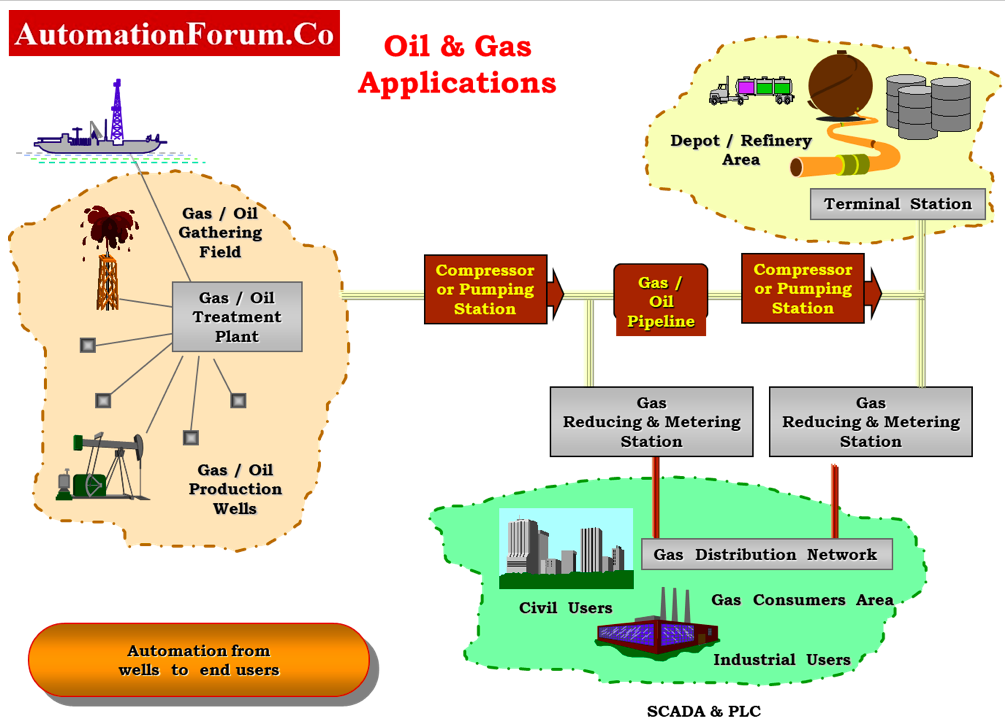

9. Oil & Gas Systems:

- SCADA system monitors wells and pumping sites, pumping pressure, pipeline flow, and compressor stations.

- It detects irregularities to prevent catastrophic events from occurring for safety.

10. Mass Transit & Railway Traction:

- Transport authorities use the SCADA system to

- Control supply of electricity to subways, trams, and trolley buses.

- To automate traffic signal indication for railways.

- To track and locate trains and buses.

- To control railway crossings.

- SCADA protocols also regulate electricity in remote locations.

SCADA in Power transmitting Systems

- Re-routing services for station maintenance

- Service Restoration

- Protective relay interface/interaction

- Voltage regulation management

- Load tap changer control

- Transformer management

- Real-time modeling.

- Automatic control of circuit isolation.

- collective switch control display

- Interface real-time single-line displays

- On-line operation and maintenance logs

- Automatic system diagnostics through system alarm management.

Some of the applications are

- Comprehensive operational planning and control

- Fuel resource scheduling

- Optimum power flow

- Network security

- Economic dispatch

- Generation dispatch control

Benefits of SCADA for Power Systems

- Improved quality of service

- Improved reliability

- Reduced operating costs

- Maintenance /Expansion of customer base

- Ability to defer capacity addition projects

- High-value service providers

- Improved information for engineering decision

- value-added services

- Flexible billing option

- Improved customer information access

- Reduced system implementation costs

- Reduced manpower requirements

The general features of a SCADA substation system are

- Substation parameter monitoring

- Controlling electrical network components remotely

- Safety tagging

- High-resolution time stamping

- The sequence of event reporting for post-event analysis

Additional features of the substation control system

- Demand side management

- Volt/VAR control

- Preventive maintenance

- Fault detection isolation and restoration.

SCADA for Power Utility Network

- Power Utility Network (PUN) software provides an electrical utility with tools to enhance system operation at a very low cost.

- The PNU software consumes real-time SCADA data.

- PNU logic is a combination of both mathematical and logical techniques.

- The present scenario is to produce and distribute quality power at the minimum investment.

- Proper operation of the electrical network & having real-time data about the network helps to achieve the required goal.

- PNU provides the user with a host of applications to distribute automation.

Features of Power Network Utilities

- Component Modeling

- State Estimation

- Bad Data Suppression

- Contingency Analysis

- Fault Isolation/Islanding

- Load Shedding

- Volt/VAR Scheduling

- Dispatcher Power Flow

- Short Circuit Analysis

- Network Topology Processor

Objectives of SCADA

There are many objectives of the SCADA System.

- Improves overall System efficiency such as capital & energy.

- Increases penetration of energy sources along with renewable energy sources.

- Reduces energy requirements at generation and transmission sections

- Increases sequence to essential loads.

The application of SCADA

- In power plants, the SCADA serves the invaluable safety and protection

- This system attempts to solve the fault that occurred and restore power quickly when a fault is experienced in a transmission line.

SCADA Advantages

- Receiving real-time information to monitor equipment

- Remote industrial control

- Storage of performance data for later analysis

- It allows for dynamic maintenance and reduces downtime

Frequently asked Questions

What are the four types of SCADA?

The SCADA systems are classified into four types

- Monolithic SCADA system,

- Distributed SCADA system,

- Networked SCADA system, and

- I-o-T SCADA system.

What is an example of SCADA?

Basically, SCADA systems control and monitors physical processes. General examples of SCADA are

- Transmission of Electricity,

- Transportation of Gas & Oil in Pipelines,

- Water Distribution,

- Traffic Lights.

What are the four functions of SCADA?

The four primary functions of the SCADA system are:

- Data Acquisition,

- Network Data Communication,

- Data Presentation,

- Data Control.

What language is SCADA?

- Most SCADA systems are now programmed using standard interfaces.

- Basically, C, or a derived programming language is used as a SCADA language.

What is the main function of SCADA?

The basic function of SCADA systems are

- Collects field information,

- Transfer it to the main computer.

- Displays the process information as a graphical representation.