Introduction

SIMATIC is a series of programmable logic controllers and automation systems developed by Siemens introduced in 1958 the series has gone through four major generations. The latest beginning with the SIMATIC S7 generation. It is purely for industrial automation, process industry, and production.

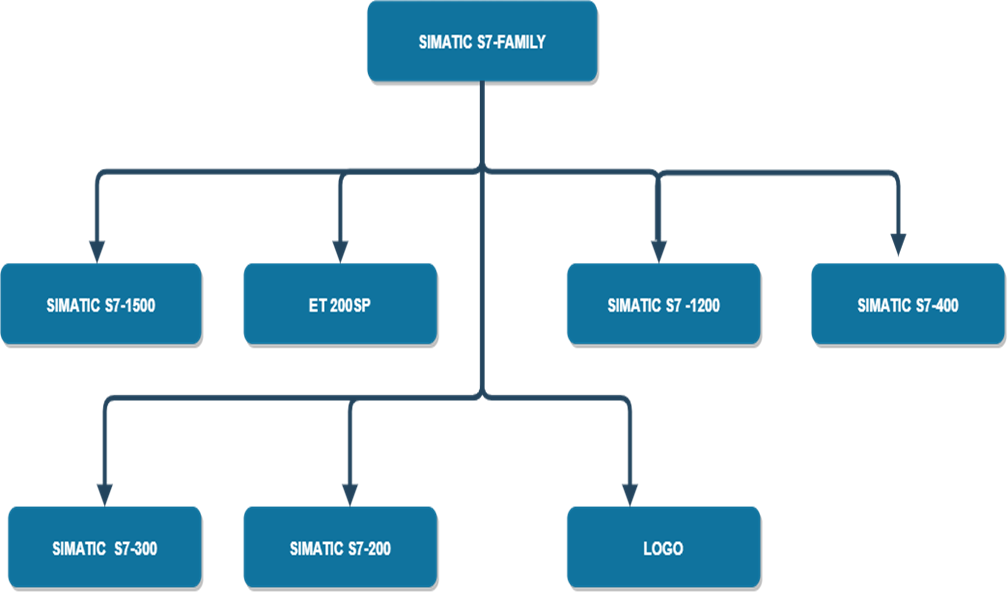

What are the various types of PLC?

- LOGO

- SIMATIC S7- 200

- SIMATIC S7-300

- SIMATIC S7-400

- SIMATIC S7-1200

- SIMATIC ET-200SP

- SIMATIC S7-1500

What is LOGO PLC?

It is a mini PLC controller of Siemens it is launched in 1996 and it is a small logic controller that brought a revolution in traditional automation. It is a perfect choice as a fast, uncomplicated, and space-saving solution for basic control tasks. It is used for small-scale automation projects in industries.

It has expansion modules so it can be added up to 24 digital input, 20 digital output, 8 analog inputs, 8 analog outputs.

What software and communication are used in the logo?

- LOGO SOFT software is used for programming purposes

- For older versions Siemens logo USB cable is used, for updated version logo plc Ethernet cable is used (RJ-45) for communication

What is SIMATIC S7-200?

- It is a smart plc the perfect combination of Siemens SIMATIC automation products and SINAMICS drive products has created new micro automation solutions that are economical reliable easy to use

- It’s a compact type plc, it also used for small scale industries

- It has 38 analog input & output capacities and 256 digital input & output capacity

- It has 7 expansion modules

What software and communication are used in S7-200?

- STEP 7 MICROWIN software is used for programming purposes

- By using RS485 Connector of the RS-232/PPI multi-master cable, Baud rate of 187kbits

- PC/PLC communication through PC adapter via MPI (MULTI POINT INTERFACE)

What is SIMATIC S7-300?

- The SIMATIC S7-300 universal controllers save on installation space and feature a modular design, modules can be used to expand the system centrally or to create decentralized structures according to the task at hand and facilitate a cost-effective stock of spare parts

- It is a compact/ modular type plc where a wide range of modules is used. It can add Input and Output, communication modules maximum up to 32 modules

- Since it is a rack-type PLC in each rack it can expand up to 8 Input & Output modules, through the Interface modules we can transfer the data to the other modules.

- In the S7-300 PLC panel cabinet, we can expand up to four racks

- S7-300 is based on a serial communication system. It is used for small-scale and process industries.

S7-300 CPU is also available in:

- Standard

- Compact

- Fail safe

- Technology T version

- It has standard CPU models which are CPU 312, CPU314, CPU315-2DP, CPU 315-2PN/DP, and CPU317-2PN/DP

- FAIL-SAFE CPU models are CPU 315F-2DP, CPU315F-2PN/DP, and CPU317F-2PN/DP

- S7-300F failsafe CPUs are used in safety applications for machines and plant

What is a Fail-Safe CPU?

This CPU always reads the equipment or process variables for an unaccepted or unsafe condition or risk. If such a condition occurs it will react immediately and shut down the equipment or process to fail-safe condition as programmed.

What is Safety PLC?

Safety PLC is designed to safeguard any plant failures from harming people, equipment/machinery, and the environment. Whenever any of the specified hazardous conditions occur, the safety PLC program will detect it and will drive the plant into a safe condition, mostly into a shutdown state.

What software and communication are used in s7-300?

- STEP 7 V5 for programming

- WINCC flexible for HMI, SCADA

- TIA PORTAL STEP 7 professional

- RS485/PROFIBUS, PC adapter via MPI, ETHERNET cable for PROFINET it is for communication purpose

What is SIMATIC S7-400?

- The s7-400 has been designed specifically for system solutions in the field of manufacturing and process automation. This process controller is ideal for data-intensive tasks that are especially typical for the process industry

- It is a high-performance CPU in the high-end performance range and it is applicable for plants with a high requirement in the high-end performance range

- It can be operated with up to 21 expansion units. It is a modular type PLC

- 8 slots each for 1 CPU with its own Inputs/Outputs

- Up to six interface modules can be plugged in

- The redundant power supply can be used in the Standard S7-400 system for up to 18 modules

- S7-400 CPU are generally more powerful and faster than the s7-300, the backplane rack–based parallel bus that allows faster communication between the CPU and its modules

- S7-400 based on the parallel communication system

- It has standard CPUs which are 412, 414, 416 and 417

- Fail-safe CPUs is 414f and 416f

- Integrated PROFINET function in CPU 416-3 PN/DP

What software and communication are used in S7-400?

- STEP 7 V5 for programming

- WINCC flexible for HMI, SCADA

- TIA PORTAL STEP 7 professional

- RS485/PROFIBUS, PC adapter via MPI, ETHERNET cable for PROFINET it is for communication purpose

What is SIMATIC S7-1200?

- It is a basic controller when it comes to flexibility and efficiency performing automation tasks in lower to the medium performance range

- It is designed as compact and versatile

- The I/O’s are already integrated and it can also accommodate additional I/O modules to enlarge the capabilities of the plc

- SIMATIC s7 -1200 CPU with safety integrated, handle both standard and safety tasks

- All CPUs of s7-1200 can be expanded by an additional signal board and up to 3 communication modules depending upon the CPU. 6 DI/4DQ integrated, expandable by one signal board.

- Signal modules of cpu1212c accept up to two modules but CPU 1214c, 1215c, and 1217c both accepts up to 8 signal modules

- Modules with 8 ,16,32 Inputs & Outputs channels are available

- Integrated PROFINET interface in SIMATIC s7-1200 can be used for programming CPU and for communication with other controllers, drives, supports serial communication, PROFIBUS, IO link

WORK MEMORY: 50KB

LOAD MEMORY: 1MB

What are work memory and load memory?

Work memory of a PLC is like a RAM of a PC;

Load memory of PLC is like the hard disk of a PC

What software and communication are used in s7-1200?

- TIA PORTAL v13, v14 and v15

- PROFINET, Industrial Ethernet (RJ-45), PROFIBUS DP, MODBUS can be communicated by adding additional modules

What is SIMATIC ET 200SP?

- The ET 200SP from Siemens is one of the most popular remote I/O units used on the market today, one end features a set of input and output modules that are installed close to the sensor and actuators on the factory floor –the other end is connected to the plc in the control room by a single cable by PROFINET

- It is a distributed controller based on SIMATIC ET200SP

- It is a compact I/O system for control cabinets, the highest flexibility, and performance, and also fail-safe peripheral modules

- Interface modules connect the ET200SP station to the bus system of the automation landscape. we can choose among 5 PROFINET interface modules, high-speed functionality, or a high feature interface modules for the proven PROFIBUS field bus

How to identify the modules?

The peripheral modules are labeled with different colored squares to identify easily the type of modules

- Digital Input modules (DI):8/16 channels color (white)

- Digital Output modules (DQ):4/8/16 channels color (black)

- Analog Input modules (AI):4 channels color(light blue)

- Analog Output modules (AQ); 2/4 channels color (dark blue)

What software and communication are used in ET 200SP?

- TIA PORTAL v13, v14 and v15

- Industrial Ethernet(RJ-45) PROFINET, PROFIBUS for PROFINET (Interface module IM155-6PN), for PROFIBUS (Interface module IM155-6DP)

What is SIMATIC S7 -1500?

- It is an advanced PLC in the SIMATIC s7 family. This PLC provides a fast response and the highest system performance and the CPU is available in standard and failsafe versions. Using the SIMATIC S7-1500 controller gives you top performance and built-in viability into the future. You can turn the most sophisticated machine designs, which provides reliable assistance as you work your way through the digital transformation

- SIMATIC S7-1500 execute the user program and network the controller with other automation components

- S7-1500 fail-safe CPU used for safety application of machines and plants

- The scope ranges from standard and fail-safe CPU for small to mid-size requirements offering compact size design with integrated inputs and outputs

- S7-1500 has an inbuilt display and keypad that allows for configuration and diagnostics faults and errors it will show in the display and can change the IP addresses in the display itself without the need of external system, for security purposes password changing is done in the display itself

- It can expand the modules up to 32

- Standard CPU range from CPU1511-1PN for small and for medium size application 1518-4PN/DP, CPU range depends upon the application, communication, processing speed of plant or industries

- It can be used for high-speed applications such as assembly lines

- Redundant CPUs is synchronized via PROFINET

What software and communication are used in s7-1500?

- TIA PORTAL V13, V14 and V15

- We can migrate the project from step 7 software to TIA PORTAL software

- Industrial Ethernet(RJ-45) PROFINET, PROFIBUS

Advantages and Disadvantages of PLC

What are the pros and cons?

Let see the pros of the PLC SYSTEM

- It is highly versatile save space in and around the cabinet

- It reduces the spare parts and inventory costs

- It increases the reliability, flexibility, and accuracy

- It has the ability to easily communicate and connect with computers and various protocols like PROFIBUS, PROFINET, MODBUS TCP/IP

- It has a low maintenance cost

- Since its automation system, it reduces the manpower for supervisory

- It can be used in hazardous areas

- In industries, we can add additional motors, compressors by just adding additional modules in the PLC (modular)

- It can be used in remote control capability

- The errors of machinery can be easily sorted out

Let see the cons of the PLC system

- Some older PLC (s7-200) programs cannot be migrated by the latest software like TIA PORTAL

- Some compact PLC is not intended for high-speed applications

These are the limited cons in the plc system

Applications of PLC

What are the major areas of application of PLC in the industry?

PLC acts as the heart of the automation system. Now we will see the top automation application list where plc is used

- Steel industry

- Glass industry

- Paper industry

- Textile industry

- Cement industry

- Food industry

- Oil and gas plant

- Wind turbine system

- Robotic automation system

- Chemical industry

- Refrigeration process

- Pharmaceutical industry

Apart from this what are the application used in daily life in various fields?

Industrial Side:

- Transporting conveyor system

- Labeling and packing systems in food industries

- Automatic filling machines in beverage

- Refrigeration field temperature monitor and control, recording data

- Boilers controlling and monitoring recording data

- Water treatment controlling and monitoring recording data

- Oil and gas process industries controlling and safety purposes

- Cement industries for manufacturing or mixing the raw materials

- Induction motors, servo motors control, and automatic tuning according to pressure or temperature(PID) and also to identify the faults