Working Principle Of Bourdon Gauge

If a tube having oval cross section is subjected to pressure its cross section tends to change from oval to circular.

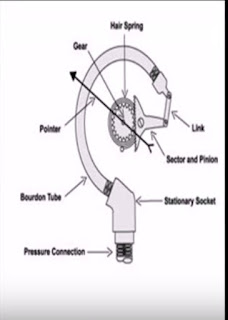

Construction of a Bordon Gauge

Bourdon tube gauges consist of a circular tube.

One end of the tube is fixed while the other end is free to undergo elastic deformation under the effect of pressure.

Fixed end is open and pressure which is to be measured is applied at the fixed end.

Free end is closed and undergoes deformation under the effect of pressure.

Due to applied pressure the circular tube tends to uncoil and become straight along the dotted line.

Working of Bourdon Gauge

As the pressure is applied at the fixed end free end undergoes deformation.

The free end is attached with sector which further meshes with the pinion on which pointer is mounted.

Deformation of the pointer is transferred to pointer via this mechanism.

As a result point undergoes deflection and shows the pressure reading on calibrated dial.

Advantages of Bourdon Gauges

1.Inexpensive

2.Simple Design

3.Good accuracy except at low pressure.

4.High-pressure range.

5.It can be easily used with electrical devices like LVDT.

Disadvantages of Bourdon Gauges.

1.Susceptible to shock and vibration

2.Gauges are subjected to hysteresis

Related Topics

Basics of Pressure Measurement

Pressure Measurement – Manometer

Classify Pressure Measuring Instruments