Ultrasonic Level Detectors

Ultrasonic sound waves with frequencies of 1 to 5 megahertz can be used to detect liquid or solid levels.

Ultrasonic are sound waves but are at higher frequencies that cannot be detected by the human ear.

The most common kind of ultrasonic transducer consist of a piezoelectric crystal.When a voltage is applied to the plates the piezoelectric crystal expands or contracts.If the voltage is alternating at an ultrasonic frequency,the crystal expands and contracts at same the same ultrasonic frequency.The crystal vibrates and these vibrations can be transferred to a diaphragm to produce ultrasonic sound waves.

Piezoelectric device can be mounted in the bottom or in the top of a vessel.The liquid surface acts as a reflector and the transducer receives the reflection of its transmitted pulses.The transducer is connected to a transmitter and to a receiver,into which the echo is fed.The transmitter and receiver are both connected to an echo timer which measures the amount of time between the emission of the sound wave and the reception of echo.The elapsed time can be converted into units of level of liquid.

Application of Ultrasonic Level detector

For situation where it is impractical or undesirable to install an instrument inside a tank ,non penetrating ultrasonic sensors are available.

Advantages of ultrasonic level detectors

1.Can be used in any tank size

2.Can be used in a vacuum

3.Can be used under high pressure

4.Relatively easy to maintain because they don’t have no moving parts.

Disadvantages of Ultrasonic level detectors

1.Expensive

2.sensitive to wide range of temperature variations.

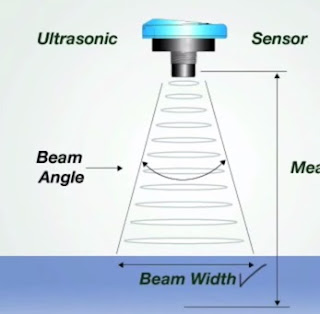

Selection consideration – Ultrasonic sensor

1.Choose a sensor range that at least as tall as the tank,doubling sensor margin to add margin against higher temperatures,condensation and turbulence.

2.Tank height is defined as the distance from the installed face of the transducer down to the bottom of the tank.

3.Riser height is the distance from the face of the transducer to top of the tank.

4.Fill height is defined as the distance from the bottom of the tank,upto the maximum desired liquid height.

5. Deadband is defined as the minimum distance from the face of the transducer from which the sensor can measure.

Related Articles