- What is temperature?

- Why temperature measurement is important?

- What are the different types of temperature measurement devices?

- Resistance temperature detector (RTD)

- Advantages of RTD over the thermocouple

- Thermistor

- Advantages of thermistor over RTD and thermocouples

- Thermocouples

- Advantages of thermocouples over RTD and thermistor

- RTD Vs Thermocouple Vs Thermistor

- How to select a proper temperature sensor for your application?

- What are the major industries where temperature measurement is inevitable?

What is temperature?

We can define temperature as the degree of hotness and coldness of an object or an environment. We can also determine the kinetic energy of a matter by the temperature measurement. It is a scalar quantity that would help us to determine the direction of heat flow between two objects. Temperature is an expression that indicates the physical properties of matter.

Why temperature measurement is important?

Temperature measurement is frequently done in many industrial processes. The chemical and petrochemical process reactions are dependent on temperature and also most industries do temperature measurements.

- If proper temperature control is not done then it could lead to plant failure

- Safety of the industrial plant, people, and also the devices can be achieved

- Better quality can be achieved

- Maintenance costs can be reduced

What are the different types of temperature measurement devices?

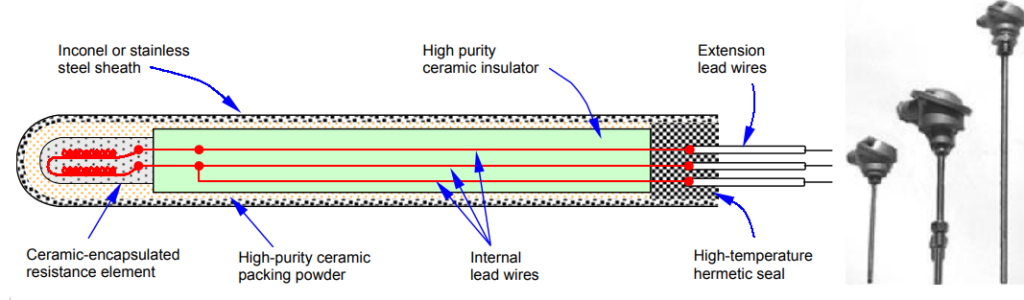

Resistance temperature detector (RTD)

The RTD would determine the temperature by measuring the resistance of the wire. The working principle of the RTD is that if the temperature of the wire increases then the resistance to the flow of electricity would also increase. RTD can be used to do the measurement of temperature accurately. To determine the temperature and resistance, a constant current would be applied and then the voltage drop through the resistor can be checked. There are different types of RTD according to the sensing element which is used in it. Nickel, copper, and platinum are the most used sensing element in an RTD. Basically, it is a two-terminal device and it can be operated by using a small constant current source.

RTD’s are available in 2 wire, 3 wire, and 4 wire configurations and they are selected according to the required accuracy. Mostly four-wire and three-wire configurations are used widely due to their accuracy. RTDs are costly when compared to other types of temperature sensors. The response time of the RTD is faster than the thermocouple but slower than the thermistor.

Advantages of RTD

- High accuracy

- Low drift

- Wide operating range

- Response time is faster than the thermocouple

- Accurate and more sensitive than the thermocouple

- It doesn’t need any extension cables like thermocouples

- It can be used for precision applications

- Stability and repeatability

Disadvantages of RTD

- RTDs are less sensitive to small temperature changes when compared to the thermistors

- Response time is high

- Requires current source

- Costly, very expensive than the thermocouples

Advantages of RTD over the thermocouple

- Used in furnaces for automatic temperature measurements

- Due to its compactness, it replaces thermocouples

- It doesn’t need a lot of extension wires when compared to the thermocouples and thermistors

- It can be used to measure very low to very high-level temperature measurements

- Because of its electrical output, it is used where a feedback system is required and thus corrective actions can be taken in the automated systems

- Good stability in the high-temperature range

Thermistor

This is a two-terminal device, it is a ceramic-like semiconductor device the resistance of the thermistor decreases with the temperature. Basically, it is a thermally sensitive transducer there are NTC and PTC thermistors. The NTC thermistors have a negative temperature coefficient and it would reduce their resistance with an increase in temperature these thermistors are mostly made up of cobalt, nickel, iron, copper oxides, etc. PTC thermistors are thermistors that have a positive temperature coefficient and in this, their resistance would increase with an increase in temperature. The thermistor is a resistor that would change its resistance according to the temperature.

This device would only have small errors due to the lead resistance when compared to the RTD. In order to do the operation of the thermistor current must pass through it so that the voltage can be measured and then we can calculate the resistance. When current flows through the thermistor then it would dissipate heat. The suitable temperature range of an NTC thermistor is from -55 to 200 C.

Advantages of thermistor

- Very sensitive

- Resistance changes rapidly with the temperature

- A small current is required

- Self-heating errors are very low

- Lead resistance issues are very low

Disadvantages of thermistors

- The resistance and temperature relationship are highly nonlinear, whereas in RTD it is very linear

- The narrow operating range for a single unit

- Self-heating issues are more than RTD

- Less stable than RTD

Advantages of thermistor over RTD and thermocouples

- Lower cost than RTD

- Higher sensitivity than the RTD

- Less sensitive to shock and vibrations

- Very sensitive than RTD and thermocouple

- More accurate than the RTD and thermocouple

- There is no need for four-wire bridge like an RTD

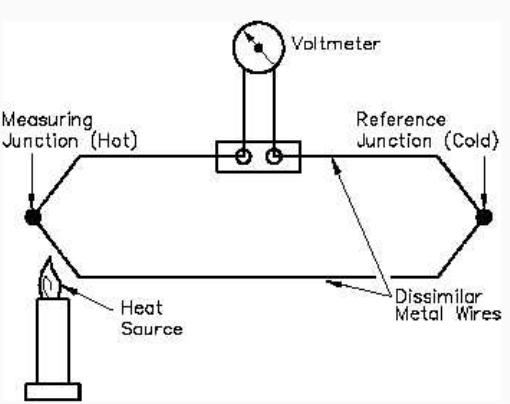

Thermocouples

This kind of temperature sensor is mostly made up of two dissimilar metal conductors and these conductors would be joined at one end. This junction would be called the hot end, thermocouples would be connected to some EMF measuring instrument at the cold end. In case any two dissimilar metals are joined together voltage will be created and this is due to the temperature difference in this junction. The thermocouples are composed of two junctions the measuring junction and the reference junction. The temperature of the reference junction is known and the temperature of the other junction is calculated by using the thermoelectric properties of the material. A thermocouple would do the measurement of temperature between two junctions and not the absolute temperature so one of the junctions would be maintained at a known temperature and the other one measures the process temperature. These temperature sensors have a protection tube called thermowell so that it can be used in harsh process environments.

Advantages of thermocouple

- Rugged construction

- Low cost

- Capable to measure a wider range of temperatures than the RTD

Disadvantages of thermocouple

- It can’t be used in areas with high radiation

- Response time is slower than the RTD

Advantages of thermocouples over RTD and thermistor

- Self-powered

- Less costly than the RTD

- Ruggedness is better than the other two

RTD Vs Thermocouple Vs Thermistor

| Thermocouple | RTD | Thermistor | |

| Temperature range | -270 to 1800 C | -250 to 900 C | -100 to 450 C |

| Sensitivity | Low | High | High |

| Price | Cheap | Costlier than the other two | Cheap |

| Linearity | Moderate | Best | Moderate |

| Ruggedness | Best | Moderate | Low |

| Speed | Less than thermistor | Less than thermistor | Very fast response |

| Size | Bigger than the other two | Small | Small |

| Stability | Not as stable as RTD | Stable over a long period | Less stable than the other two |

| Vibration effect | Less affected | Affected by shock and vibrations | Less affected than RTD |

How to select a proper temperature sensor for your application?

- It must be selected according to the environment

- Level of accuracy and repeatability

- Required response time

- Length of the sensor probe

- Cost of the sensor

- Temperature range

- Form of output

What are the major industries where temperature measurement is inevitable?

- Food industry

- Chemical industry

- Automotive industry

- Solar energy conversion

- Petrochemical industries