What is a Pressure Transmitter ?

A pressure transmitter is a transducer that converts pressure into an electrical signal.

It outputs both analog and digital signals corresponding to the pressure.

A pressure transmitter measure three phenomena : Differential Pressure,Gauge Pressure,Absolute Pressure.

The most common and useful industrial pressure measuring instrument is the differential pressure transmitter.

This instrument senses the difference in pressure between two ports and produces an output signal with reference to a calibrated pressure range.

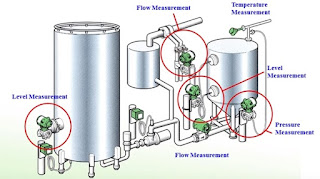

Pressure Transmitter Applications

Pressure transmitters are commonly used to measure the pressure inside of industrial machinery or in industrial processes.They are used in various industries such as oil and gas,refining,chemical,pharmacy and so on.

Pressure transmitters are widely used in industry to measure flow,level and pressure.

Basics of Pressure Transmitter

It can monitor pressure drop across valves and can be used to monitor pump control.

DP flow measurement is one the most common applications for differential pressure transmitter.

By measuring the difference in fluid pressure while the fluid flows through a pipe,it is possible to calculate the flow rate.For differential pressure flow measurement,a primary and secondary element are used.The primary element is designed to produce a difference in pressure as the flow increases.There are many different types of primary element.The most common being the orifice plate,venturi,flow nozzle,and pitot tube.

The secondary element is the differential pressure transmitter.It is designed to measure the differential pressure produced by the primary element as accurately as possible.In particular,it is important that the differential pressure measurement is not affected by changes in the fluid line pressure,temperature or other properties such as ambient temperature.

A good DP transmitter will ensure that the differential pressure is measured accurately,regardless of other changing parameters and will reliably transmit signal to represent the differential pressure.

The DP flow transmitter output signal may also include square root extraction for flow calculation,although it is common for this function to be handled in control system.

In a typical control loop,the transmitter signal is fed to the controller where output is used to regulate the flow rate through a control valve.

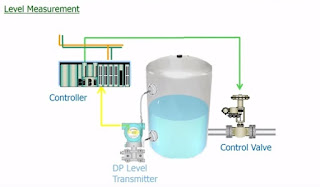

Differential Pressure transmitter can also be used for measuring tank level by measuring the pressure.

The transmitter is installed at the bottom of the tank whose level is to be detected.

In case of a sealed tank,a transmitter with capillaries measures the differential pressure between the upper side and the bottom side.

The liquid inside the tank at the bottom creates pressure which is higher than the pressure at the top.The difference in these pressures can be used to calculate the level.

In case of an open tank,the transmitter measure the differential pressure between the liquid inside the tank and reference atmospheric pressure.

In typical control loop,the transmitter signal is fed to the controller whose output is used to regulate the tank level through a control valve.