- What is an Emergency shutdown system?

- What are the major components of an ESD?

- When would the emergency shut down system be initiated?

- What are the major functions of an emergency shutdown system?

- What is the importance of relief valves in an ESD system?

- Why ESD is required in industries?

- What is SIS?

- What are the major requirements of SIS?

- What are safety instrumented functions?

- What is SIL level?

- Advantages of ESD system in industries

- What are the applications of the ESD systems?

What is an Emergency shutdown system?

The emergency shut down system is a quick closing system that can be seen in many industrial plants. It can be activated manually or automatically in case of any emergencies, if it is activated it would close all the valves which need to be closed, and also it would shut down all the machinery. The ESD system would reduce the risk in a plant and it would provide a quick and safe means to stop the plant or process if any fault conditions occur.

What are the major components of an ESD?

This system consists of field-mounted sensors, valves, and trip relays, system logic for processing incoming signals, alarms, and HMI units. This system is capable to process the input signals and activate the outputs according to the emergency situation. It also has relief valves, remote shut down stations,

When would the emergency shut down system be initiated?

A few examples of ESD activation conditions are listed below

- In case of fire

- In case of blackouts

- Low pressure in tanks or other equipment

- If the control air pressure is low

What are the major functions of an emergency shutdown system?

- It would shut down a part of the system or equipment

- Isolation of electrical equipment

- It would stop hydrocarbon flow

- Emergency ventilation control

- Depressurize/blowdown

- Isolate hydrocarbon inventories

What is the importance of relief valves in an ESD system?

Pressure relief valves are used in many industries in order to release the pressure from a pipeline or from a tank. These types of valves would be fitted in a pipeline that could be spring-loaded or pilot operated. Pilot-operated valves are mostly used in tanks, these valves would ensure the proper operation. These valves would control the critical operations in a process, in case the pressure exceeds a certain limit, it could create a lot of damage this can be prevented by the relief valves.

Spring-loaded pressure relief valves

Why ESD is required in industries?

The ESD system is an emergency system that is designed to respond to hazardous conditions in a plant. ESD systems are used worldwide to prevent hazardous conditions in industry and thus provide security to the operator and also to the machinery. Maintenance costs can be reduced because of an ESD system, if we use an ESD system in an industry it will act as a preventive measure against fault conditions so it would prevent this faulty condition and due to this, there won’t be any damage to the process equipment.

What is SIS?

The safety instrumented system (SIS) would provide safety to the industrial process system. It is also called an emergency shutdown system. The major purpose of an SIS system is to keep the process in a safe state in case the predetermined setpoints have been exceeded or in case the industrial process goes beyond the safe operating conditions, the SIS system will act and shut down the plant or process in a safe manner. The SIS is composed of safety functions with sensors, logic solvers, and also actuators. The SIS would read sensors, do the calculation and logic which is required to determine the dangerous conditions, and generates the output for the final control element to prevent the hazardous situations.

- Sensors for signal input

- Interfacing of the input signal and processing

- Logic solver with power and communications

- Output signal processing

- Final control elements such as actuators, valves, switching devices

What are the major requirements of SIS?

The safety instrumented system must be independent of all other control systems, that control the same equipment. Due to this, we can determine the functionality of the SIS is not compromised. The SIS must perform its control function which is called the safety instrumented function.

What are safety instrumented functions?

A safety instrumented function is a safety function that would be implemented by SIS in order to achieve and maintain a safe state. So basically, it is an action of a safety instrumented system to bring the process to a safe state. The SIF would indicate the hazardous conditions.

What is SIL level?

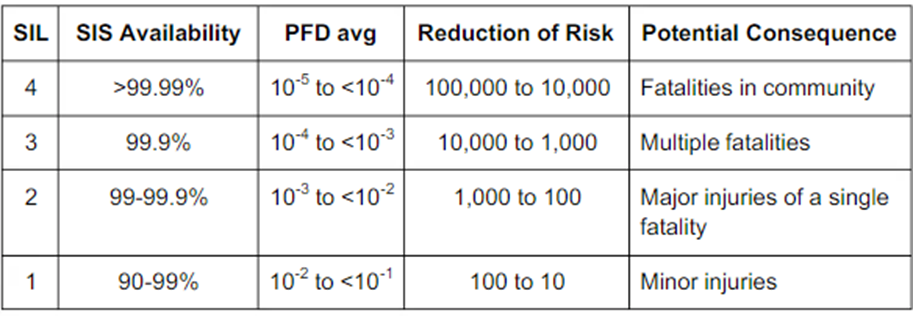

The safety integrity level is created to determine the probability of the failure on demand for the safety system to work. The SIL would show us to which extent a process would perform safely and also fail safely. Basically, SIL is the measure of the safety risk for a given process and it would show the tolerable failure rate for a process. The requirement of the SIS can be determined by the hazard analysis, if this analysis shows that there is proper safety protection then there is no need for SIS. The below table shows the discrete level for specifying the safety integrity requirements of the safety instrumented functions to be allocated to the safety instrumented system. The SIL level would let us know to what extent a process can be expected to fail safely. The higher the SIL the greater the risk of failure and because of this there will be stringent safety requirements.

PFD – Probability of failure on demand

Advantages of ESD system in industries

- It would improve the overall safety of the facility

- It would prevent the personnel injury, loss of life, equipment damage, loss of production

- It would prevent asset damage and production loss

- Company reputation can be improved

- Environmental pollution can be avoided

- Production can be improved

What are the applications of the ESD systems?

- Aerospace

- Oil and gas industries

- Food processing

- Petrochemicals

- Electronics manufacturing

- Steel industry