- Flow measurement methods

- What are the types of flow sensors?

- Types of the inferential flow sensor

- Types of differential pressure flow sensors

- Types of velocity flow sensors

- Types of volumetric flow sensors

- Types of Mass flow sensors

- How should we select a flow sensor for our application?

- What could be the major cause of the errors in flow meters?

- What is a Flow Sensor?

- How Many Types of Flow Sensors are Available?

- What is the Difference Between a Pressure Sensor and a Flow Sensor?

- How Do Water Flow Sensors Work?

Flow is the measurement of the fluid velocity per unit area in a pipe or a conduit. By using a flow sensor, we could measure the amount of gas, liquid, or vapor. A flow meter consists of a transducer and also a transmitter.

Flow measurement methods

Direct method

In this type of flow measurement, the quantity which is to be measured would be compared to a standard value. So we are exactly measuring the quantity which is to be measured, mostly in this measurement we are measuring the fluid mass.

Types of direct flow measurement

- Turbine flow sensor

- Coriolis sensor

Indirect method

This is the most common method of flow measurement because in most cases direct measurement of the flow is not possible. So indirect method is mostly used in this method the sensor would measure the flow of the fluid indirectly like transmitting sound waves through the fluid flow.

Types of indirect fluid flow measurement

- Differential pressure

- Magneto inductive

- Vortices frequency

- Ultrasonic

- Venturi meter

- Orifice plate

- Pitot tube

- Annubar

- Flow nozzle

- Thermal mass flow sensor

- Positive displacement flow sensor

What are the types of flow sensors?

- Inferential flow sensor

- Differential pressure flow sensor

- Velocity flow sensor

- Volumetric flow sensor

- Mass flow sensor

Inferential flow sensor

In this type of flow sensor, the measurement of flow is done indirectly, like temperature and pressure of the flow would be measured to determine the flow rate. Types of inferential flow sensors are magnetic sensors, turbine sensors, target sensors, etc.

Mass flow sensor

Fluid mass would be directly measured in this type of flow measurement. It would measure the mass or amount of fluid that flows through a tube to determine the flow. Coriolis and thermal mass flow sensors are examples of the mass flow sensor.

Differential pressure flow sensor

In this type of flow sensor, the pressure difference of the flow due to the pipe construction would be utilized to determine the flow rate.

Velocity flow sensor

This type of flow sensor would measure the flow velocity through a pipe. So the velocity of the fluid will be multiplied by the area that the fluid flows through.

Volumetric flow sensor

Flow measurement would be done by measuring the volume of the fluid which flows through a pipe.

Types of the inferential flow sensor

Turbine flow sensor

In this type of flow measurement, a rotor will be placed in the pipe and this rotor is supported by two bearings. A magnetic pick-up would be placed at the top of the pipe’s section where the rotor is installed. When the fluid flows the rotor would rotate and this would create a frequency. The rotor pulse would be calculated to determine the flow rate.

Advantages of the turbine flow sensor

- Easy installation

- It is not affected by the variation in the fluid density

- Compact

- Less head loss

- Good temperature and pressure ratings

- Good repeatability and range

Disadvantages of the turbine flow sensor

- It can’t be used with high viscous fluids

- Due to the moving parts damages could happen if the speed increases

Applications of the turbine flow sensor

- Military applications

- Petroleum industry

- Energy fuel and cryogenic flow measurement

Target flow sensor

In a target flow sensor, an obstruction would be placed in the flow path so when the fluid comes in contact with the object a force would be exerted on the object. This force can be measured and this measured force will be proportional to the flow rate. The target size would vary according to the measured liquid.

Advantages of the target flow sensor

- These flowmeters can be used with liquid slurries

- It can be used for low turbulence flow metering

Applications of the target flow sensor

- It can be used to measure dirty fluids

- Liquid, vapor, and gas measurements can be done

Types of differential pressure flow sensors

Venturi meter

This type of sensor is a tube that has a cone structure. The operation of the Differential pressure flow meters is based on Bernoulli’s principle which states that if the fluid velocity increases then the pressure would decrease and vice versa.

The tube structure is in a way that there is a convergent part and also a divergent part. So when the fluid flows through the converging part of the tube then it would be accelerated and during this process, the fluid pressure will be dropped. The end part of the tube section is expanded and in this part, the fluid flow would almost gain its actual pressure. So the velocity and pressure relation is checked and according to this, we could determine the flow rate.

Advantages of venturi meter

- Good accuracy

- High velocity and pressure recovery

- It can be used with fluids that have small solid particles

- High repeatability

- Less maintenance

Disadvantages of venturi meter

- Installation cost is high

- Abrasive or sticky fluid would affect the measurement

Applications of venturi meter

- Measurement of compressible and non-compressible fluids

- Gases and liquid flow measurement

- Chemical industries

- Oil and gas

- Power industries

Orifice plate

This type of flow sensor has a disc-type structure and it is installed in the straight run of the pipe. The orifice plate would be installed perpendicular to the fluid flow. This plate would have a hole in the center of it so when the fluid comes in contact with the plate then it would flow through the hole and the flow velocity would be increased and the pressure would be decreased. So when the fluid flows beyond the orifice plate the flow velocity and pressure would change. The relation between the pressure drop and the velocity can be observed to determine the flow rate.

Advantages of the orifice plate

- Economical

- Maintenance is easy

- Generates high differential pressure

- It can be easily replaced

- No moving parts

- High accuracy

Disadvantages of orifice plates

- Permanent pressure loss is high

- It can’t be used with dirty fluids

- Frequent calibration is needed

- Measurement is affected due to the variation in density, viscosity, etc.

Applications of the orifice plate

- Neutral gas transfer

- Gas and fluid measurement

- Refining

- Oil and gas

Pitot tube

A pitot tube can be considered as a probe that has two parts and is capable to sense static and dynamic pressure. This type of flow sensor is used for the non-uniform flow measurement, so due to the non-uniform flow, there will be variations in the pressure and velocity of the flow. The probe would be inserted into the fluid, the impact unit of this flow meter consists of a tube with one end bent at right angles towards the direction of the flow. The static section of the tube end will be closed but it would have a small slot that can be seen in the side of the unit.

The static pressure would be measured at the wall of the flow conduit and the dynamic or impact pressure is calculated from the flowing pressure. Velocity head will be converted to impact pressure. The flow measurement is done by the measuring difference between the static and dynamic pressure. Mostly these tubes are installed by welding a coupling on the pipe and after that, the probe would be inserted through the coupling.

Advantages of Pitot tube

- Installation is easy

- No pressure loss

Disadvantages of Pitot tube

- It can’t be used with dirty fluids

- Not suitable to measure the sticky fluids

- It is sensitive to the upstream disturbances

- Low accuracy

Applications of Pitot tube

- It can be used to measure the non-uniform flow

- Measurement of velocity and direction in combustion studies and in heat transfer work

- It is used to determine the magnitude and direction of the gas velocity

- Measurement of the aircraft’s airspeed

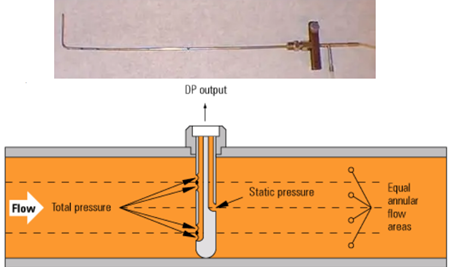

Annubar

The operation of the Annubar is similar to the Pitot tube. The only difference is that the Annubar has more than one hole in the pressure measuring chambers. So this device has many velocity sensing openings which are subjected to the fluid flow. So from this, the static and dynamic pressure is calculated and the difference between these two can be calculated to determine the fluid flow.

Advantages of Annubar

- Easy installation

- Low-pressure drop

- Low maintenance

- High accuracy

Disadvantages of Annubar

- It can’t be used with high viscous fluids

- Measurement is single point

Applications of Annubar

- Used for liquid and gas flow

- It can be used for low and high-pressure applications

Flow nozzle

This is another type of differential pressure flow sensor and it can handle a higher flow rate than the orifice plate. This type of flow meter is similar to the venturi but there is no recovery cone. Basically flow nozzle is a restriction to fluid flow and it has a cylindrical throat section. Pressure taps are required to measure the difference in static pressure which is created by the flow nozzle, and it will be located, upstream and downstream in the pipe. This type of flow meter can be used to determine the flow of liquids with suspended solids. The cost and size of this meter are very less, the pressure loss of this meter is really high. This type of flow meter is used when high velocity and pressure recovery are needed.

Advantages of the flow nozzle

- It can be used to detect high flow

- Measurement of liquids with solid particles is possible

- Low-pressure drop than the orifice plate

Disadvantages of the flow nozzle

- It can’t be used with viscous fluids

- It must not be used with fluids that have sticky particles

- More maintenance

- It can’t be used with large size pipes

Applications of the flow nozzle

- High-pressure steam flow

- High-temperature steam flow

- Mostly it is used for gas measurement than fluids

- It is used with a pressure transmitter

- It is used with flow control valves

Types of velocity flow sensors

Magnetic flow sensor

In this type of flow sensor, a magnetic field would be applied to the pipe or conduit in which the flow is meant to be measured. This operating principle of this flow sensor is based on Faraday’s law, which states that when a conductive fluid passes through a magnetic flux an EMF will be created. So when the conductive fluid passes the magnetic field then a voltage will be induced. The voltage which is formed will be proportional to the flow velocity.

Advantages of the magnetic flow sensor

- It doesn’t have any moving parts and also there is no fluid obstruction

- Very less pressure drop

- Non-contact measurement

- Good electrical insulation and corrosion resistant

- It can be used with extremely low flow

- It can be used for bidirectional flow measurement

- Measurement won’t be affected by viscosity

Disadvantages of the magnetic flow sensor

- Only conductive fluid can be measured, we won’t be able to measure gases and hydrocarbons with this

- Expensive

Applications of the magnetic flow sensor

- Measurement of slurries and dirty fluids can be done

- It can be used with acid, base, water, and also for aqueous solution

Vortex flow sensor

In this type of flow measurement, an obstruction would be placed perpendicular to the flow. When the fluid passes through the obstruction then the flow would be disrupted and vortices would be formed. This vortex shedding frequency can be used to determine the velocity of the fluid. Mostly pressure transducers are utilized to measure the vortices.

Advantages of the vortex flow sensor

- High accuracy

- There are no moving parts so less maintenance

- It can be used with liquid, gas, and steam

- Pressure drop is really low

- It can be used with fluids with different density

Disadvantages of the vortex flow sensor

- It can’t be used with abrasive or dirty fluids

- Measurement would be affected if the flow velocity is low

- In order to create proper vortices, a specified straight pipe run is required for the upstream and downstream of the sensor

Applications of the vortex flow sensor

- Cryogenic fluids

- Hot and chilled water

- Condensate measurement

- Acids

- Solvents

- Measurement of steam

Types of volumetric flow sensors

Positive displacement flow sensor

Positive displacement flow sensor

This type of flow sensor is used for the measurement of gases and liquids. There are several types of positive displacement sensors such as rotating paddle sensors, oscillating piston sensors, oval gear sensors, sliding vane sensors, and bi rotor sensors. Mostly a positive displacement sensor has a moving part, the mechanical components of the PD sensors are driven due to the energy from the flow. The energy that drives the sensor would create a pressure drop in the inlet and outlet of the meter.

Advantages of positive displacement flow sensors

- It can be used with viscous liquids

- Certain type of PD meter doesn’t need electrical power for their operations

- Good rangeability

Disadvantages of positive displacement sensors

- It can’t be used with liquids that have suspended particles

- Chances of mechanical wear are high because of the moving parts

- Over-speeding could damage the sensor

Applications of the positive displacement flow sensors

- Measurement of very low and very high viscous fluids

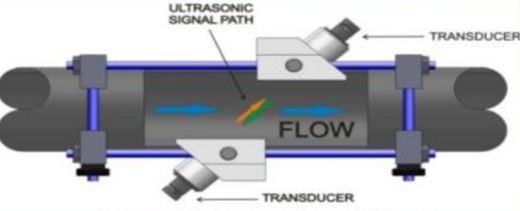

Ultrasonic flow sensor

In this type of flow sensor, sound waves would be used to determine the flow rate. There are three methods of measurement in this type of sensor the Doppler shift method, deflecting beam method, and the transit time method. In the above image, we can see two transducers are placed in opposite directions. Both these transducers would emit sound waves to each other and the time taken to receive the two signals is measured to determine the fluid velocity.

Doppler shift method

In this method, the sound waves would be transmitted through the fluid and these waves would be reflected from the fluid to the receiver in the flow sensor. The received sound wave frequency can be measured to determine the flow rate.

Deflecting beam method

In this method, sound waves are transmitted at the right angle to the flow. The liquid would deflect the sound wave. This deflection can be measured to determine the flow rate.

Transit time flow

In this method, a diagonal beam would be transmitted across the flow path and this beam would be transmitted against the flow. The sound travel against the flow would be slow and this can be measured to determine the flow rate.

Advantages of ultrasonic flow sensors

- Non-intrusive

- There is no pressure drop

- Good accuracy

- Good range

- High reliability

Disadvantages of the ultrasonic flow sensor

- It can’t be used with dirty liquids

- A straight pipeline would be required for the flow measurement

- The transmission path will be affected by attenuation

Types of Mass flow sensors

Coriolis mass flow sensor

The working principle of this flow sensor is based on newton’s second law which states that force is equal to the value of the mass multiplied by the acceleration. In this meter, the flow will be divided into two parallel tubes and these tubes would be vibrated by the electromagnetic drive coil. So when the fluid flows through these tubes then there will be an upward and downward force and due to this there will be a tube deflection and this deflection is known as the Coriolis effect. The deflection of the tube corresponds to the mass flow in the tube.

Advantages of Coriolis flow sensor

- High accuracy

- Very low-pressure drop

- It can be used for liquid and gas flow

Disadvantages of Coriolis flow sensor

- Costly

- Mounting is difficult

Applications of Coriolis flow sensor

- Metering of natural gas consumption

- Custody transfer

- Syrups and oil monitoring

- Gas & liquid flow measurement

- Solid content concentration can be determined

Thermal mass flow sensor

In this type of sensor, the flow measurement is done by utilizing the thermal properties of the fluid. In this sensor, a specified amount of heat will be provided to the heater which is situated inside the sensor. So when the fluid flows, a portion of the heat will be lost and if the flow is increased then the heat loss will be increased too. This loss of heat would be measured by the sensor’s temperature measuring instrument.

Advantages of thermal mass flow meter

- Measurement is not affected by variation in pressure

- Pressure drop is really low

- Less maintenance because there are no moving parts

- Installation is really easy

- Economical

Disadvantages of thermal mass flow meter

- Measurement would be affected by moistures

- Sensitivity is less for high flow

- If there is any variation in gas composition then it would require recalibration

- Accuracy would be reduced due to the flow sensor build-up

Applications of the thermal mass flow sensor

- Measurement of gases like nitrogen, hydrogen, helium

- Measurement of pure gases

How should we select a flow sensor for our application?

- It must be selected according to the type of liquid, like clean or dirty

- Properties of the liquid should be considered like pressure, density, viscosity, conductivity, temperature, pressure drop, etc.

- It should be selected by considering the plant conditions, as the size of the pipeline, straight pipe runs, enclosures, etc.

- Flow sensors should be selected according to the required performance like accuracy, repeatability, stability, and pressure loss

- Range requirements

- Installation space

- It must be selected by considering the flow stream like if it has corrosive or erosive materials

What could be the major cause of the errors in flow meters?

- It could be due to the variations in the fluid properties such as density, viscosity, pressure, and temperature

- Meter orientation

- Flow disturbance

What is a Flow Sensor?

A flow sensor is a device used to measure the flow rate of a fluid either liquid or gas through a pipeline or conduit. It quantifies the flow in terms of volume per unit time (e.g., liters per minute) or mass per unit time (e.g., kilograms per hour). Flow sensors are essential in various industrial applications, including water management, chemical processing, and HVAC systems, as they help monitor and control fluid flow to ensure optimal system performance.

How Many Types of Flow Sensors are Available?

There are several types of flow sensors, each suited for specific applications:

Velocity Flow Sensors:

- Magnetic Flow Sensor

- Vortex Flow Sensor

- Turbine Flow Sensor

- Ultrasonic Flow Sensor

- Thermal Mass Flow Sensor

Volumetric Flow Sensors:

- Positive Displacement Flow Sensor

- Oval Gear Flow Sensor

- Rotary Piston Flow Sensor

Mass Flow Sensors:

- Coriolis Mass Flow Sensor

- Thermal Mass Flow Sensor

Each type operates on different principles, making them suitable for specific fluid properties and application environments.

What is the Difference Between a Pressure Sensor and a Flow Sensor?

| Aspect | Pressure Sensor | Flow Sensor |

| Function | Measures the pressure of a fluid within a system, usually in terms of force per unit area (e.g., psi, bar). | Measures the rate at which fluid flows through a system, usually in terms of volume or mass per unit time. |

| Application | Used to monitor and control the pressure in systems like hydraulic presses, pneumatic systems, and fluid distribution networks. | Used in systems where monitoring the quantity of fluid moving through pipes or conduits is critical, such as in water treatment, fuel metering, and HVAC systems. |

| Key Feature | Measures the force exerted by the fluid on the sensor’s surface. | Quantifies the amount of fluid passing through the sensor, helping to manage flow rates and ensure proper system operation. |

How Do Water Flow Sensors Work?

Water flow sensors typically consist of a turbine or rotor that spins as water passes through it. The rotation speed of the turbine is proportional to the flow rate of the water. This rotational movement is converted into electrical pulses by a magnetic or optical sensor. The frequency of these pulses is then used to calculate the flow rate, providing real-time monitoring of water usage.

Some water flow sensors may also use ultrasonic waves, where sound waves are sent through the water, and the time it takes for these waves to travel through the flow is measured. The difference in travel time is used to calculate the flow rate.