- Repeatability

- What is meant by Repeatability?

- What is the reason for poor repeatability?

- How to improve the measurement for repeatability?

- Reproducibility

- What is meant by Reproducibility?

- What are the possible causes of poor Reproducibility?

- How to improve the measurement for reproducibility?

- Difference between Repeatability Vs Reproducibility

- Why repeatability & reproducibility is important?

- What is meant by Gage R & R?

- Why do we use gage R&R?

- How do you measure repeatability & reproducibility?

- What is a good gage R&R value?

- What are methods to find GRR?

Repeatability & Reproducibility (R&R) studies evaluate the precision of a measurement in various fields. Before beginning the R&R investigation, it is essential to ensure that the equipment has been accurately calibrated.

Repeatability

What is meant by Repeatability?

Repeatability is the accuracy of output values acquired by applying the same input repeatedly over a short time period while maintaining the same measurement conditions (including environmental temperature), instrument, observer, location, and application.

Repeatability is the variation between successive measurement done using the same gauge

Eg: Measuring Result is “10.12mm, 10.11mm, 10.15mm, 10.14mm, 10.23mm”

What is the reason for poor repeatability?

There are two possible causes:

Equipment

- Instrument needs maintenance

- Instrument might be more rigid

Appraiser

- Environmental condition like lightning, noise

- Physical condition (Eyesight)

How to improve the measurement for repeatability?

- Taking average of multiple average.

- Mistakes proofing

- May need maintenance

Reproducibility

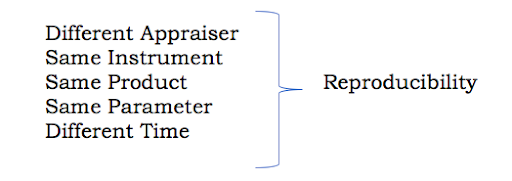

What is meant by Reproducibility?

Reproducibility describes the closeness of output readings for the same input when there are changes in the method of measurement, observer, measuring instrument, location, conditions of use & time of measurement.

Also reproducibility can be said as the difference in the average of the measurement made by different people using the same instrument when measuring the identical characteristics on the same part.

Example : In same instrument with two operators

Operator 1 measuring value – 10.12mm, 10.15mm, 10.13mm

Operator 2 measuring value – 12.13mm, 12.18mm, 12.19mm

What are the possible causes of poor Reproducibility?

- Measurement procedure is not clear

- The Operator does not have adequate training in reading and using gauge

- Operational definition not established

How to improve the measurement for reproducibility?

- Have several operator measure the same part and take average

- Improvement can be done with one operator only

- Mistake proofing

- Ensure consistency

- Calibration on the gauge dial may not clear

Difference between Repeatability Vs Reproducibility

| Repeatability | Reproducibility |

| Measurements is done in same instrument with same location, same procedure, same observer, same condition and repetition over a short interval of time | Measurement is done in same instruments, same part with different appraiser. |

| Occurs due to gauge error | Occurs due to operating error |

| Improve by one operator | Improve by collecting reading from different operator |

Why repeatability & reproducibility is important?

Repeatability is considered to be essential for obtaining accurate measurements, assuring reliability, meeting goals for product quality.

In terms of reproducibility, measurements must be consistent. It is the degree to which a tool can deliver the same outcome when used again in similar situations.

What is meant by Gage R & R?

If the measurement uncertainty is too great, the measurement system

might not work.Then the measurement system variance is analyzed by gage R&R.

Why do we use gage R&R?

A measuring system’s variation’s magnitude and its causes can both be determined with the use of gauge R&R. Gage R&R also helps to identify the sources of variation in a measurement system. After that, compare this variability to the overall variability to determine the measuring system’s actual variability.

How do you measure repeatability & reproducibility?

Repeatability

The repeatability is measured from standard deviation for repeatability (?ev)

The ?ev = R?k

where ?ev – Equipment Variation

k = 1/d2

R – Average of the range of trial of each part

d2 – function of the number of values (r) per part

Reproducibility

The repeatability is measured from standard deviation for reproducibility (?ov)

?ov=xdiff.k22 -EV2nr

where

?ov – Operator Variation

xdiff – Difference between High & Low Appraiser Averages (xh-xl)

n = number of parts

r = number of trials

k2= 1/d2& d2 is the function of the number of values (r) per part

What is a good gage R&R value?

- % Gage R&R is under 10%, the measurement system is considerable.

- % Gage R&R is between 10 % to 30%, the measurement system may be acceptable for some applications

- % Gage R&R is over 30%, the measurement system is unacceptable.

What are methods to find GRR?

The Gage Repeatability & reproducibility is found by following methods:

- Average and range Method

- ANOVA (Analysis of Variance)

- EMP (Evaluating the Measurement Process)