Integral (or Reset) Control

Integral control (also called Reset control) can be used when unacceptable amounts of offset occur in a process with proportional control. Integral control is used to return the value of the controlled variable to the set point. This mode of control is most often used along with proportional control. For example, if a process needs proportional control but must also be maintained very close to a set point, proportional plus integral control may be used.

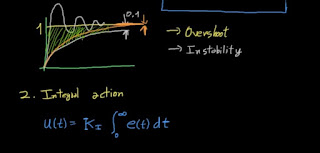

In very basic terms, integral control action will combine with the proportional control action to modify (or boost) the normal proportional output of a controller in the proper direction until offset is corrected.

“Integral” is a mathematical term used to describe how this type of control action is accomplished. A mathematical computation, called integration, determines how much to compensate for the offset. Using mathematical symbols, this is f(x) dx.

The integral value is set into the controller. The value of the manipulated variable is changed in proportion to the amount of offset. So, if the deviation from set point is doubled over a previous measurement, the final control element (a valve, for example) may be moved (closed or opened) twice as fast to compensate. Proportional plus integral control is also referred to as PI control and proportional plus reset control. The use of both means that the advantages of both are present, i.e., the elimination of offset.