Vibration measuring instruments, Accelerometers

The instruments which are used to measure the displacement, velocity or acceleration of vibrating body are called vibration measuring instruments.

What is Machine Vibration?

Machine vibration is simply the back-and-forth movement of machines or machine components. Any component that moves back and forth or oscillates is vibrating.

A machine component may vibrate over large or small distances, quickly or slowly, and with or without perceptible sound or heat. Machine vibration can often be intentionally designed and so have a functional purpose. At other times machine vibration can be unintended and lead to mechanical damage.

It is important to measure the unintended vibration to know about the machine condition, especially for motors and compressors.

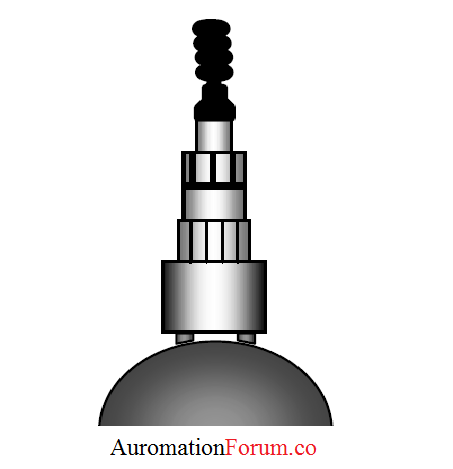

Accelerometers for measuring vibration

Three different accelerometers are required in most plants. A low-frequency accelerometer is required to measure the low frequencies that cannot be measured with a displacement transducer. A medium range accelerometer is also required for various measurements. The frequency response is often from about 2 Hz to about 10 KHz. 15 or 20% on the high end. The sensitivity of these accelerometers is often 100 mV/g. High-frequency accelerometers are also required in most plants. These accelerometers can measure frequencies up to 100 KHz, however, the amplitude accuracy may be +20%.

There are mainly two types of vibrometers which are used to measure the vibration of the piezoelectric Accelerometer and Seismic type.

Piezoelectric type

Most accelerometers are based on the piezoelectricity crystal principle. A piezoelectric crystal responds to a mechanical motion by generating an electric voltage.These crystals are used in this manner also for delay lines in some radar applications. In most applications, the frequency response of a crystal is determined by size. The larger the crystal, the lower the frequency. The smaller the crystal, the higher the frequency. Since the output of a crystal is so low, the signal must be amplified in, or very close to, the accelerometer. If this amplification is not accomplished, the signal may get lost in the electronic noise.

Seismic displacement measuring type

A seismic accelerometer is a displacement sensing accelerometer. It is a spring-mass-damper. The seismic mass is connected to a frame by damper and spring which is connected to the vibrating body. The displacement of the seismic body due to the instrument vibration is measured by the displacement transducer.

Mounting Vibrometer

The magnetic mount should sit securely on the surface with the accelerometer positioned in the prescribed orientation. To ensure that the accelerometer is firmly attached, the surface to which the magnetic mounting is stuck should be even.

The signal produced by the accelerometer is dependent on the orientation in which the accelerometer is mounted since the amplitude of vibration varies in different directions.