P&ID and Common Abbreviation

INTRODUCTION

A piping and instrumentation diagram (P&ID) is a diagram in the process industry which shows the piping of the process flow together with the installed equipment and instrumentation. The P&ID are also used to operate the process system. P&ID shows all of piping including the physical sequence of branches, reducers, valves, equipment, instrumentation and control interlocks.In this session we are going to discuss about P&ID and Common Abbreviation.

Based on Institute of Instrumentation and Control, a piping and instrumentation diagram (P&ID)is defined by the diagram which shows the interconnection of process equipment and the instrumentation used to control the process. In the process industry, a standard set of symbols is used to prepare drawings of processes. The instrument symbols used in these drawings are generally based on International Society Automation (ISA) Standard S5.1

Functions of P&ID

The main function of P&ID is related with a significant role in the maintenance and modification of the process that it describes. It is critical to demonstrate the physical sequence of equipmenvt and systems, as well as how these systems connect. During the design stage, the diagram also provides the basis for the development of system control schemes, allowing for further safety and operational investigations, such as the hazard and operability study (HAZOP).

There are a few rules in preparing a P&ID whereby there are item that should be included and some items should not.

A P&ID should include:

- Instrumentation and designations

- Mechanical equipment with names and numbers

- All valves and their identifications

- Process piping, sizes and identification

- Miscellaneous – vents, drains, special fittings, sampling lines, reducers, increasers and swaggers

- Permanent start-up and flush lines

- Flow directions

- Interconnections references

- Control inputs and outputs, interlocks

- Interfaces for class changes

- Seismic category

- Quality level

- Annunciation inputs

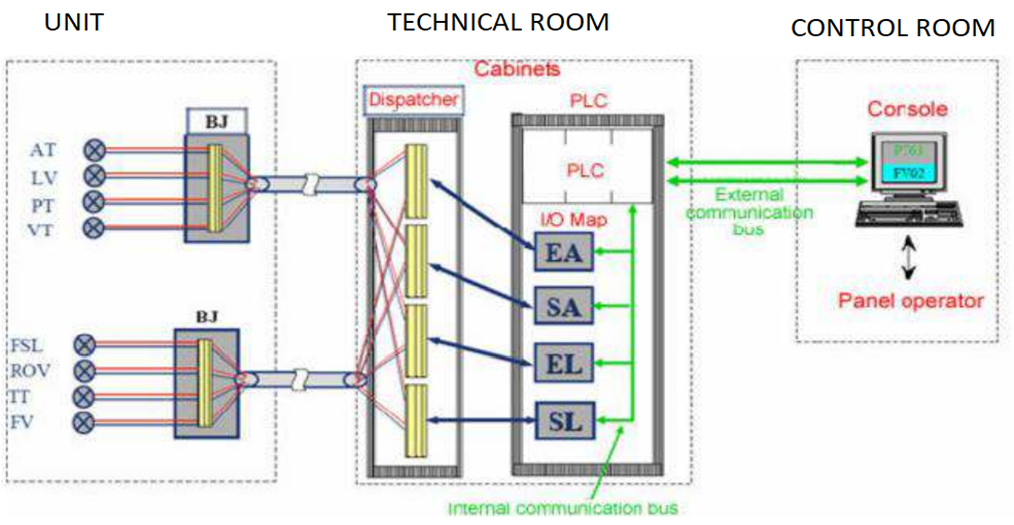

- Computer control system input

- Vendor and contractor interfaces

- Identification of components and subsystems delivered by others

- Intended physical sequence of the equipment

A P&ID should not include:

- Instrument root valves

- control relays

- manual switches

- primary instrument tubing and valves

- pressure temperature and flow data

P&ID Common Abbreviation

| AEAOV BE CR DP DT FC FCV FE FG FHC FHS FI FIC FM FQR FQI FR FRC FS FT Ftd HCV HS LC LCV LG LHC LI LIC LR LS LT Ltd MOV | Analyzer Element (Chemical Composition)Air Operated Valves Burner Element (flame detector) Conductivity Recorder Differential Pressure Density Transmitter (also specific gravity and Baume) Flow Controller Flow Control Valve Flow Element Flow Sight Glass Flow Hand Control (manual) Hand Switch in Flow Loop Flow Indicator Flow Indicating Controller Flow Meter (Pos. Displ. or Turb) Flow Qantity Recorder Flow Quantity Indicator Flow Recorder Flow Recorder Controller Flow Switch Flow Transmitter Flow Transducer Hand operated Control Valve Hand switch Level Controller Level Control Valve Level Gage Glass Level Hand Control (manual) Level Indicator Level Indicating Controller Level Recorder Level Switch Level Transmitter Level Transducer Motor Operated Valve | MTPA PC PCV PdI pHT PI PIC PIT PR PS PT PTd PZV RO ST SV TC TCV TE TI TIC TR TRAP TS TSA TT TTd TW TY WE XA XVE XVS ZV | Motion TransmitterPressure Alarm Pressure Controller Pressure Control Valve Differential Pressure Indicator pH Transmitter Pressure Indicator Press. Indicating Controller Press. Indicating Transmitter Pressure Recorder Pressure Switch Pressure Transmitter Pressure Transducer Pressure Relief Valve Restriction Orifice Speed Transmitter Solenoid Valve Temp. Controller Temp. Control Valve Temp. Element Temp. Indicator Temp. Indicating Controller Temp. Recorder Steam Trap or Airvent Temp. Switch Temp. Switch Alarm Temp. Transmitter Temp. Transducer Thermowell Relay in Temperature Loop Weight Measuring Element Annunciator Vibration Detector Vibration Switch Safety Shut-down (Pilot) valve |